Stainless Steel Heat Exchanger U Pipe

September 23, 2023

Induction pipe bending and steel elbow fittings differences

October 5, 2023Outline

- Introduction

- Definition of a Reducer in Piping

- Types of Reducers in Piping

- Selection of Reducers in Piping

- Advantages and Uses of Concentric Reducers

- Role of Reducers in Pipeline Systems

- Practical Application of Pipe Reducers

- Comparison between Increasers and Reducers

- Conclusion

| Type | concentric reducer(con reducer) , eccentric reducer(ecc reducer), seamless reducer , butt welding reducer,carbon steel reducer(CSreducer), mild steel reducer(MS reducer), alloy steel reducer(AS reducer), stainless steel reducer(SS reducer)… |

| Size | 1/2″-48*(DN15-DN1200) |

| Varieties | SCH5,SCH10,SCH20,SCH30,STD,SGP, SCH40, SCH60, XS, SCH80, XXS,SCH100,SCH120,SCH140,SCH160 |

| Standred | ANSI B 16.9/ANSI B16.28/MSS SP43/MSS P75/IS2311/JIS 2312/JIS2313/ DIN2615 /GB-12459/GB-T13401,Gost17378 |

| Materia | Carbon steel: ASTM A234 GR WPB , ST37.2 , ST35.8…… Alloy steel: A234 WP5/WP9/WP11/WP22/WP91, A420 WPL6,A860 WHPY 42/52/60/65/70/80….. Stainless stee: A403 WP304/TP304 , WP304L/TP304L, WP316/TP316,WP31 6L/TP316L, WP321/TP321 , WP310/TP310…… |

| Surface treatment | Carbon steel:Shot blasted, black painting, rust-proof oil, transparent oil, galvanizing,, hot galvanizing Alloy steel:Shot blasted, black painting, rust-proof oil, transparent oil, galvanizing. hot galvanizing Stainless steel: pickled,Polish |

| Application Fields | Chemical Industry /Petroleum Industry /Power Industry/Metallurgical Industry Building Industry /Ship-building Industry |

Introduction

The introduction sets the stage for the topic, explaining the importance of reducers in piping systems.

Definition of a Reducer in Piping

A reducer in piping is a component used in pipe systems to reduce the pipe size from a larger to a smaller bore (inner diameter). The length of the reduction is usually equal to the average of the larger and smaller pipe diameters. Reducers are used where the pipe on the upstream side of the reducer is larger in size than the downstream side.

Types of Reducers in Piping

There are two main types of reducers in piping: concentric and eccentric reducers.

- Concentric Reducers: In this type, the center line of the larger pipe end aligns with the center line of the smaller end. They are often used in vertical piping systems and for suction side (inlet) of pumps to ensure air does not accumulate in the pipe.

- Eccentric Reducers: The center line of the larger pipe end aligns with the bottom side of the smaller end. They are used in horizontal piping systems to prevent accumulation of gases.

Selection of Reducers in Piping

The selection of reducer type depends on various factors, including:

- The direction of fluid flow (vertical or horizontal).

- The nature of the fluid (whether it has a tendency to hold gases or solid particles).

- The velocity of the fluid.

- The pressure condition in the system.

Advantages and Uses of Concentric Reducers

Concentric reducers have several advantages:

- They allow for a smooth and gradual mixing of fluids.

- They ensure a steady and uniform velocity, which reduces the chances of erosion.

- They are easier to manufacture than eccentric reducers, making them more cost-effective.

Concentric reducers are used in a variety of applications, such as in pump inlets and installations where fluid accumulation is not a concern.

Role of Reducers in Pipeline Systems

Reducers play a vital role in pipeline systems. They allow for changes in pipe diameter, which can help control fluid velocity and pressure. They also enable the connection of pipes of different diameters, facilitating versatility in pipeline design and installation.

Practical Application of Pipe Reducers

This section could provide specific examples of how pipe reducers are used in various industries, such as oil and gas, chemical processing, power generation, and water treatment.

Comparison between Increasers and Reducers

While reducers decrease the diameter of the pipe, increasers (or expanders) increase it. The choice between using a reducer or increaser depends on the requirements of the piping system, including desired flow velocity, pressure conditions, and the need to prevent fluid accumulation.

Conclusion

The conclusion would summarize the main points discussed in the thesis, emphasizing the importance of understanding the role and application of reducers in piping systems.

Remember: each section of this outline could be expanded to a full chapter, with introduction, body, and conclusion segments. To reach your 6500-word count, you’ll need to conduct in-depth research on each topic and present detailed evidence, examples, and explanations.

Buttweld concentric reducer is also called welded concentric coupling. It allows from connecting a large pipe to a smaller pipe by means of welding. A concentric reducer allows welded connection between two pipes with the same center line.In concentric reducers the area reduction is concentric and the center line of the pipe on a bigger end and smaller end remains the same. These styles are normally used for vertical lines. So in concentric reducers, the pipe axis remains the same. Reducers are reversible and can be used in any direction.

Eccentric reducer is a fitting used in piping systems between two pipes of different diameters. The same fitting can be used in reverse as an eccentric increaser or expander. They are used where the diameter of the pipe on the upstream side of the fitting (i.e. where flow is coming from) is larger than the downstream side, and where there is a danger that vapor may accumulate. In Eccentric Reducer the reduction of the pipe size is achieved by decreasing the diameter of the fitting at a constant rate over a specified length, maintaining one side of the fitting horizontally.

Related posts

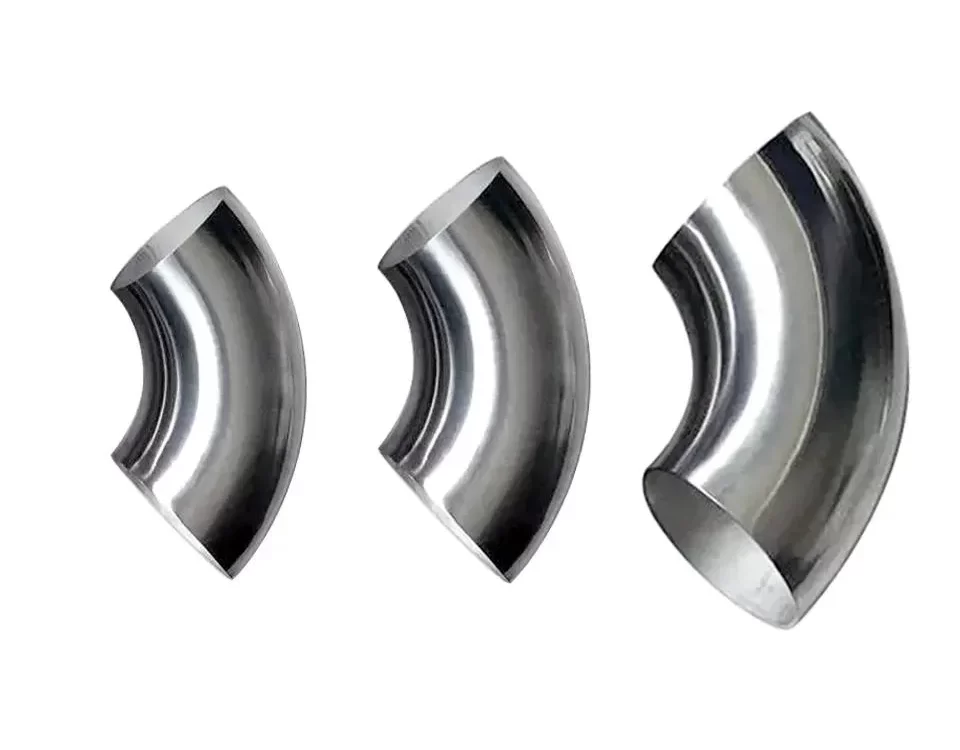

Induction bends come in standard bend angles (e.g. 45°, 90°, etc.) or can be custom made to specific bend angles. Compound bends (out-of-plane) bends in a single joint of pipe can also be produced. The bend radius is specified as a function of the diameter. For example, common bend radii for induction bends are 3D, 5D and 7D, where D is the nominal pipe diameter.

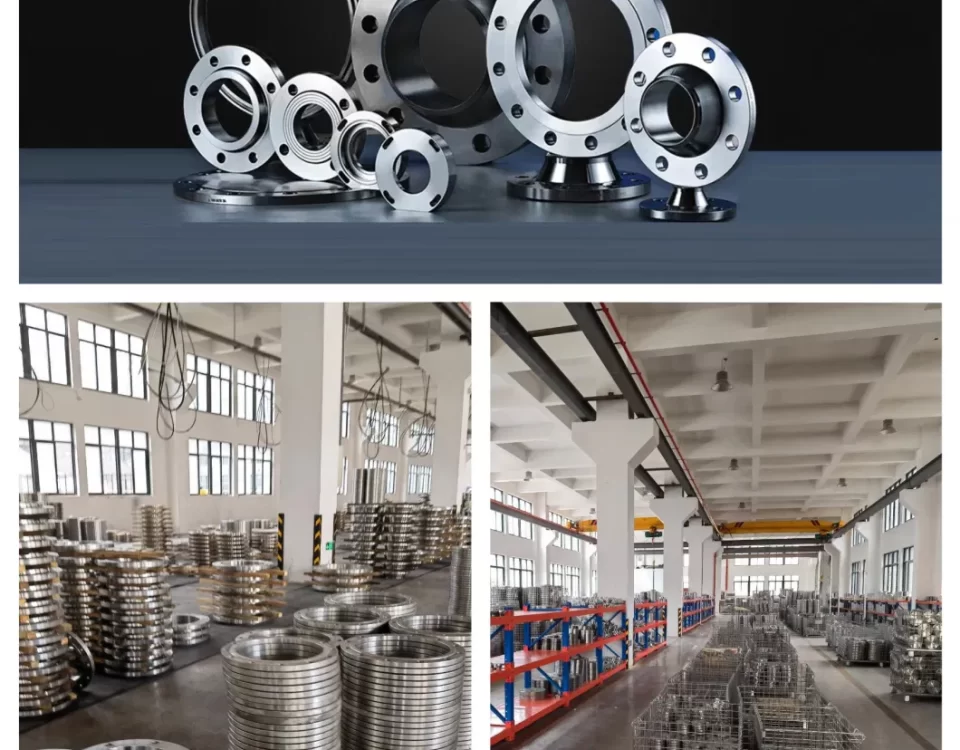

Duplex 2205 and Super Duplex 2507 stainless steel flanges are characterized by their high yield strength, which is twice that of the annealed yield strength of typical austenitic stainless steels, like 304 and 316 stainless steel flanges. Because of this, Duplex 2205 and Super Duplex 2507 steel are some of the most common grades of duplex used for flanges with Super Duplex 2507 flanges being the more corrosion resistant grade of the two.