New Type Seamless Steel Pipes Manufacturing for Automobiles

October 14, 2023

Steel Pipe for Mechanical Engineering and Machine Components steel pipe

October 21, 2023Abstract

Boilers play an integral role in many industries, and the quality of their construction significantly impacts their performance, efficiency, and safety. This paper examines the development of seamless steel tubes and pipes, pivotal components of boilers, their manufacturing processes, properties, and the advancements that have led to the creation of superior products in recent years.

Introduction

Boilers, whether in power plants, industrial setups, or residential heating systems, are incredibly important. A critical component in boiler construction is the tubes and pipes, which primarily facilitate the transfer of heat. The use of seamless steel tubes and pipes has become the industry standard due to their high tensile strength, heat resistance, and ability to withstand high pressure, among other properties.

Manufacturing Process of Seamless Steel Tubes and Pipes

Seamless steel tubes and pipes are manufactured from solid steel billets. These billets are heated to a specific temperature and then pierced to create a hollow tube shell in a process known as rotary piercing and elongation. The shell is then elongated further to achieve the desired wall thickness.

The tubes then undergo a sizing process where they are passed through a series of rollers to achieve the required diameter and thickness. After sizing, the tubes are cooled, cut to the desired length, and straightened. The final step involves rigorous inspection and testing to ensure each pipe and tube adheres to the necessary standards.

Quality Control in Seamless Steel Tubes and Pipes Production

Quality control is an essential part of the production process for seamless steel tubes and pipes. It begins with the selection of high-quality steel billets that are free from impurities. The heating process is carefully controlled to prevent the formation of undesirable by-products that could compromise the quality of the final product.

During sizing, precision is critical to achieving uniform wall thickness and diameter. Non-destructive testing methods such as ultrasonic testing and electromagnetic inspection are employed to detect any flaws or defects in the tubes and pipes. Lastly, samples are taken for mechanical and chemical analysis to ensure they meet the required properties.

Developed Seamless Steel Tubes and Pipes for Boilers

The development of seamless steel tubes and pipes over the years has been driven by the need for improved efficiency, safety, and durability in boiler systems. Modern seamless tubes and pipes have been developed to have superior mechanical strength, improved heat resistance, and better resistance to high pressure.

For example, T91 and T92 seamless steel tubes have been developed specifically for high-pressure, high-temperature boiler applications. These tubes have excellent creep resistance and are able to withstand long periods of exposure to high temperature and pressure.

In addition to material improvements, advancements have also been made in the manufacturing process. Computer-aided design and manufacturing processes have led to more precise control over the tube dimensions, ensuring consistent quality. Additionally, advanced non-destructive testing techniques have been developed to detect flaws and defects, significantly improving the reliability of the tubes.

Conclusion

The development of seamless steel tubes and pipes for boilers has been driven by the need for better efficiency, safety, and durability. Advances in material science and manufacturing technology have led to the creation of superior products that can withstand the demanding conditions in boilers. The future of seamless steel tubes and pipes for boilers is promising, with ongoing research likely to lead to even more improvements.

Future Trends and Developments

The future of seamless steel tubes and pipes for boilers is promising, with several potential advancements on the horizon. There is a growing focus on developing even more heat-resistant steel types, which could further enhance the efficiency and safety of boilers.

Moreover, advances in manufacturing technology, such as the use of AI and machine learning in quality control processes, could further improve the quality and reliability of these tubes and pipes. The trend towards sustainable manufacturing could also see the development of more environmentally-friendly production processes.

- Standards:

ASME(American society of mechanical engineers)

(1)ASME SA-106: Standard Specification for Seamless Carbon Steel Pipe for High-Temperature Service

(2)ASME SA-192M: Seamless Carbon Steel Boiler Tubes for High Pressure

(3)ASME SA-209M: Seamless carbon-Molybdenum Alloy-Steel Boiler and Superheater Tubes

(4)ASME SA-210M: Seamless Medium-carbon Steel Boiler and Superheater Tubes

(5)ASME SA-213M: Seamless ferritic and austenitic alloy steel boiler, superheater and heat exchanger tubes

(6)ASME SA178: Electric-Resistance-Welded Carbon Steel and Carbon-Manganese Steel Boiler and SuperheaterASTM(National standards)

(1)ASTM A213: Seamless ferritic and austenitic alloy steel boiler, superheater and heat exchanger tubes

(2)SA213-T2: ASME SA213 T2 has allowable stresses listed up to 1000F in the ASME Boiler Code.

(3)SA213-T9

(4)SA213-T12: Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, Heat-Exchanger Tubes.

(5)SA213-T11: The tubes are used in heat exchangers, super heaters and in boilers.

(6)SA213-T22: ASM T22 Boiler Tube is a high temperature tolerance tube that is used in acidic and corrosive environments such as the hydrochloric processing and in aluminum chloride catalyst involving applications.

(7)ASTM A 106M: Seamless Carbon Steel Pipe for High-Temperature Service

(8)ASTM A192M: Seamless Carbon Steel Boiler Tubes for High Pressure

(9)ASTM A210M: Seamless Medium-carbon Steel Boiler and Superheater Tubes

(10)ASTM A 335M: Seamless ferritic alloy-steel pipe for high-temperature servicEN(Deutsche industrie normen)

EN 10216-2 : Seamless steel tubes for pressure purposesDINDIN 17175:Seamless Tubes of Heat-resistant Steels – Technical Conditions of DeliveryJIS

(1)JIS G3461: Carbon steel boiler and heat exchanger tubes

(2)JIS G3462: Alloy steel boiler and heat exchanger tubes

(3)JIS G3463: Stainless Steel for Boiler and Heat Exchanger TubesSTAINLESS STEELS

SA213-T304:– The SA 213 Tp 304 Material consists of 18% chromium and carbon, manganese, phosphorus, sulfur, silicon and nickel in the composition.

SA213-T316: – SA213 TP316 Tube is a material standard for heat exchanger tubes that are made from 316 austenitic stainless steel.

SA213-TP321 & 347– SA213 TP321 is a specification of heat exchanger tubes that are made from the 321 austenitic stainless steel.

Standards and material for steel pipe is available at carbon, alloy, and stainless steel material.

Carbon steel: ASTM/ASME A/SA 106, ASTM A179, ASTM A192, ASTM/ASME A/SA 210, ASTM A333 Gr 1, 6,7 to Gr 9,

Alloy steel: ASTM/ASME A/SA 213 T1, T2, T5, T9, T11, T12, T22, T91, T92; ASTM A335 P1, P2, P5, P9, P11, P12, P22, P91, P92

Stainless Steel: ASTM A268, ASTM A213, TP304/L, TP316/L, 310S,309S,317,317L,321,321H, and duplex stainless steel material etc.

Common Sizes: OD from 6mm to 1240mm, thickness from 1mm to 50mm

Types: Straight boiler pipe, and U boiler steel pipe for tube exchanger bundle.

These standards specify the classification, size, shape, weight and allowable deviation, technical requirements, inspection and test, packaging, marking and quality certificate of seamless steel tubes for boiler.

Outer Diameter (OD): 13.72-914.4mm

Wall Thickness(WT): 1.65-22mm

LENGTH: 0.5mtr-20mtr

Pipe Standard:ASTM A192 ASTM A179 ASTM A556 ASTM A210 ;EN10216/BS3059;JIS G3454/G3456/G3461 ;A213 T5,T9,T11,T22,T91

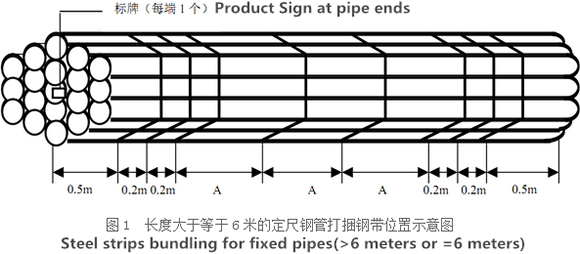

- There are probably hundreds of different methods for packing a pipe, and most of them have merit, but there are two principles that are vital for any method to work prevent rusting and Sea transportation security.Our packing can meet any needs of the customers.

w

w- Plastic caps plugged at the two sides of pipe ends

- Should be avoided by the steel strapping and transport damage

- Bundled signs should be uniform and consistent

- The same bundle(batch) of steel pipe should be came from the same furnace.

- The steel pipe has the same furnace number, the same steel grade, the same specifications.

- Standard of boiler tube

-steel-pipe.jpg)