Developed Seamless Steel Pipe Products for Boilers

October 21, 2023

STRUCTURAL and MECHANICAL STEEL SQUARE PIPE

October 26, 2023Steel pipes are an integral part of mechanical engineering and machine components. They offer strength, durability, and high resistance to wear and tear. These pipes are used in several applications, from the automotive industry to construction, and are available in different grades according to various standards.

Steel Grades

There are different steel grades available for these pipes, each providing unique properties. Some of the popular ones are:

EN 10297-1 Mechanical Engineering steel pipe

The EN 10297-1 standard is a European standard for seamless circular steel tubes for mechanical and general engineering purposes. This steel grade is known for its excellent machinability and weldability, making it ideal for various mechanical applications.

Steel grade: E235, E275, E315, E355, E470

Certification: CPR(305/2011/EU)

Chemical composition

| Steel

grade |

Elements content, % | ||||||||||||

| C | Si | Mn | P | S | Cr | Mo | Ni | Al | Cu | N | Nb | V | |

| E235 | ≤0.17 | ≤0.35 | ≤1.2 | ≤0.030 | ≤0.035 | – | – | – | – | – | – | – | – |

| E275 | ≤0.21 | ≤0.35 | ≤1.4 | ≤0.030 | ≤0.035 | – | – | – | – | – | – | – | – |

| E315 | ≤0.21 | ≤0.30 | ≤1.5 | ≤0.030 | ≤0.035 | – | – | – | – | – | – | – | – |

| E355 | ≤0.22 | ≤0.35 | ≤1.6 | ≤0.030 | ≤0.035 | – | – | – | – | – | – | – | – |

| E470 | 0.16-

0.22 |

0.10-

0.50 |

1.30-1.70 | ≤0.030 | ≤0.035 | – | – | – | – | ≥0.010 | ≤0.020 | ≤0.07 | 0.08-

0.15 |

Mechanical properties

| Steel

grade |

Delivery

condition |

Yield strength Min (MPa) | Tensile strength Min (MPa) | Elongation A, % | |||||

| Wall thickness (mm) | Wall thickness (mm) | ||||||||

| <16 | 16<T≤40 | 40<T≤65 | <16 | 16<T≤40 | 40<T≤65 | Longitudinal

direction |

Transverse

direction |

||

| E235 | +AR or +N | 235 | 225 | 215 | 360 | 360 | 360 | 25 | 23 |

| E275 | +AR or +N | 275 | 265 | 255 | 410 | 410 | 410 | 22 | 20 |

| E315 | +AR or +N | 315 | 305 | 295 | 450 | 450 | 450 | 21 | 19 |

| E355 | +AR or +N | 355 | 345 | 335 | 490 | 490 | 490 | 20 | 18 |

| E470 | +AR | 470 | 430 | — | 650 | — | — | 17 | 15 |

Dimensional tolerances

| Outer diameter

D mm |

Tolerance on D | Tolerance on T for T/D ratio | ||

| T/D≤0.025 | 0.025<T/D≤0.05 | T/D>0.05 | ||

| D≤219.1 | ±1% or 0.5mm

Whichever is the greater |

±12.5% or ±0.4mm

Whichever is the greater |

||

| D>219.1 | ±1% | ±20% | ±15% | ±12.5% |

EN 10083-2 Mechanical Engineering steel pipe

EN 10083-2 is a European standard. It specifies the technical delivery conditions for hot-rolled and general engineering steel, including non-alloy and alloy steels. The steel according to this standard is commonly used for manufacturing parts like pins, shafts, and gears.

EN 10083-2 C45 Carbon Steel Seamless Pipes Specification

| Standard | AISI, DIN, EN, GB, IS, JIS, ASTM, ASME Pipe |

| Steel C45 En 10083-2 EFW Pipe size | 5.0 mm – 1219.2 mm |

| Steel Bs En 10083-2 Tube Swg & Bwg | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg. |

| Steel Bs En 10083-2 Welded Tube Size | 6.35 mm OD To 152 mm OD |

| Carbon Steel En 10083-2 C45e Tube wall thickness | 0.020″ –0.220″, (special wall thicknesses available) |

| Carbon EN 10083-2 Grade C45 Steel Length | Single Random, Double Random, Standard & Cut length Pipe & Tube |

| Material Test Certificates (MTC) | Material Test Certificates (MTC) as per EN 10204/3.1B, EN 10204 3.1 and EN 10204 3.2, 100% Radiography Test Report, Raw Materials Certificate, Third Party Inspection Report, Fumigation Certificates, Heat Treatment Charts, EN 10083-2 Gr C45 Pipe HS Code Commercial Invoice, Form A for Generalized System of Preferences (GSP) |

| EN 10083-2 Gr C45 Form | Round, Hydraulic, ‘U’ bent or Hollow,LSAW, Boiler, Straight Pipe, Clad Pipe, Rectangular, Square Pipe Etc |

| Steel C45 En 10083-2 Value Added Service | Draw & Expansion as per required Size & Length, Polish (Electro & Commercial) Annealed & Pickled Bending, Machining Etc. |

EN 10083-2 C45 Carbon Steel Seamless Pipes Properties

| Chemical Properties | |||||||||

| Carbon | Silicon | Manganese | Phosphorous | Sulphur | Molybdenum | Nickel | Chromium | Copper | Others |

| 0.42-0.50 | max 0.40 | 0.50-0.80 | 0.045 | 0.045 | max 0.10 | max 0.40 | max 0.40 | – | – |

| Mechanical Properties | |||||

| Yield Strength | Tensile Strength | Elongation A5 min | |||

| MPa min | ksi min | MPa min | MPa min | ksi min | Percentage |

| 620 | – | – | 14 | ||

| Equivalent Designation | |||||

| DIN | EN | BS | NFA | ASTM | ASME |

| DIN 17204 Grade C45 | EN 10083-2 Grade C45 | NFA A35-552 Grade XC 48 H 1 | ASTM A519 Grade 1045 | ASME SA 519 Grade 1045 | – |

EN 10083-2 C45 Carbon Steel Seamless Pipes Standard length tolerances

| Component length (mm) | OD 30-100 mm | OD 100-254 mm |

| 10-100 | + 1.0/- 0 | + 2.0/- 0 |

| 100-600 | + 2.0/- 0 | + 3.0/- 0 |

| 600-1200 | + 3.0/- 0 | + 4.0/- 0 |

| 1200-5000 | + 5.0/- 0 | + 6.0/- 0 |

ASTM A53/A530 Mechanical Engineering and Machine Components steel pipe

ASTM A53 (also known as ASME SA53 pipe) is a carbon steel alloy used as a structural steel or for low-pressure plumbing. Its applications include mechanical and pressure applications, as well as ordinary uses in steam, water, gas, and air lines.

ASTM SA53/SA530 Mechanical Engineering and Machine Components steel pipe

ASTM SA53/SA530 is a commonly used specification for seamless and welded carbon and alloy-steel tubes. It is suitable for high-temperature service. This grade is often used in the construction of boilers, superheaters, and heat exchanger tubes.

Description

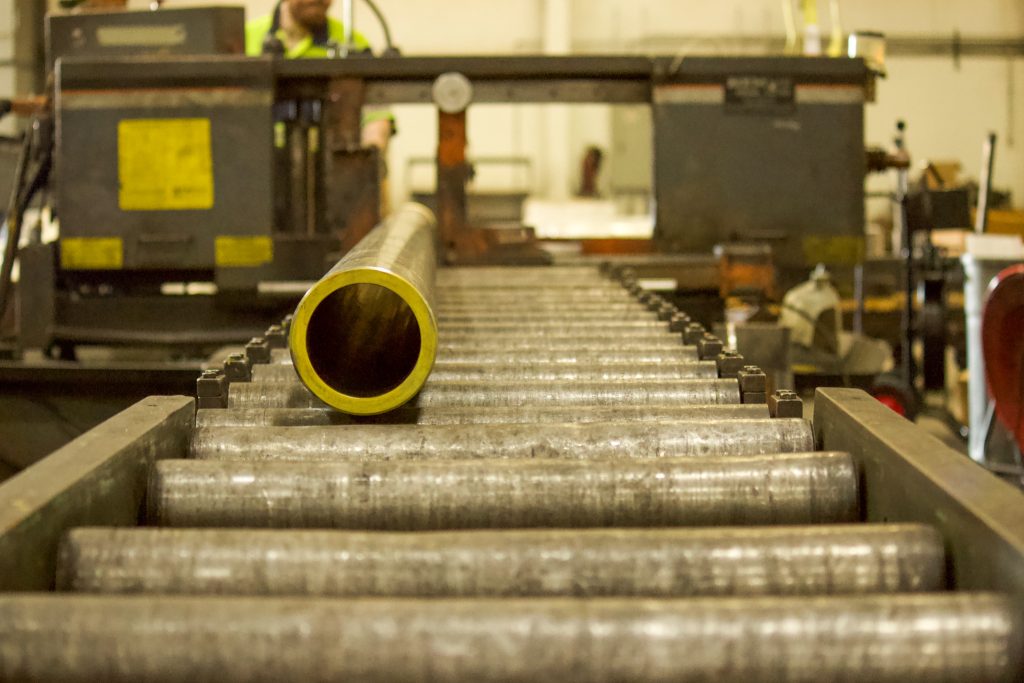

Steel pipes for mechanical engineering and machine components are generally round, but they can also be rectangular, square, or custom shapes, depending on the application. They are typically seamless or welded, with seamless pipes being preferred for high pressure or high temperature applications because of their stronger, uniform structure.

The diameter, thickness, and length of these steel pipes can vary widely based on their intended use. The surface finish can be raw, galvanized, or painted to enhance corrosion resistance or to fit the aesthetic requirements of the application.

Specification Standard

The specification standard of a steel pipe defines the mechanical and chemical properties of the steel, as well as the manufacturing processes, such as welding or heat treatment, that the pipe should undergo. The standard also outlines the testing methods and inspection protocols that should be used to ensure that the steel pipe meets the quality and safety requirements.

The mentioned standards, EN 10297-1, EN 10083-2, ASTM A53/A530, and ASTM SA53/SA530, are widely accepted and used around the world, each providing guidelines for specific types of steel and applications. These standards help ensure that the steel pipes used in mechanical engineering and machine components are safe, reliable, and high-quality.