The difference between ERW, SSAW, LSAW

November 2, 2021Introduction to basic knowledge of alloy structural steel

November 16, 2021Basic knowledge about oil pipeline

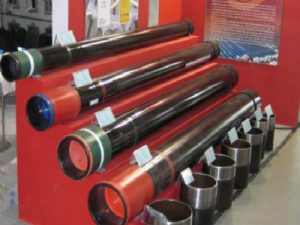

1. Explanation of special terms related to petroleum pipeline

API: It is the abbreviation of American Petroleum Institute in English, and Chinese means American Petroleum Institute.

OCTG: It is the abbreviation of Oil Country Tubular Goods in English, which means special oil pipes in Chinese, including product oil casing, drill pipe, drill collar, coupling, short joint, etc. According to statistics, for every one meter drilled, about 62kg of oil well pipe is required, including 48kg of casing, 10kg of tubing, 3kg of drill pipe, and 0.5kg of drill collar.

Tubing: The tubing used in oil wells for oil production, gas production, water injection and acid fracturing.

Casing: A pipe used to line the borehole from the ground surface to prevent the well wall from collapsing.

Drill pipe: A pipe used in a wellbore.

Line pipe: a pipe used to transport oil and gas.

Coupling: Used to connect two threaded pipes and a cylindrical body with internal threads.

Coupling material: the pipe used to make the coupling.

API thread: the pipe thread specified in the API 5B standard, including tubing round thread, casing short round thread, casing long round thread, casing buttress thread, line pipe thread, etc.

Special buckle: non-API thread buckle type with special sealing performance, connection performance and other properties.

Failure: Deformation, fracture, surface damage and loss of original functions under specific service conditions. The main forms of tubing and casing failure are: collapse, slippage, rupture, leakage, corrosion, adhesion, wear and so on.

2. Petroleum related standards

API 5CT: Specification for Casing and Tubing

API 5D: Drill Pipe Specification

API 5L: Specification for line pipe

API 5B: Specification for processing, measurement and inspection of casing, tubing and line pipe threads

GB/T 9711.1: Technical delivery conditions of steel pipes for oil and natural gas industry Part 1: Grade A steel pipes

GB/T 9711.2: Technical delivery conditions of steel pipes for oil and natural gas industry Part 2: Grade B steel pipes

GB/T 9711.3: Technical delivery conditions of steel pipes for oil and natural gas industry Part 3: Grade C steel pipes.

3. Converted value between English system and metric system

1 inch (in) = 25.4 millimeters (mm)

1 foot (ft) = 0.3048 meters (m)

1 square inch (sp.in) = 645.16 square millimeters (mm2)

1 pound (lb) = 0.45359 kilogram (kg)

1 pound per foot (lb/ft) = 1.4882 kilograms per meter (kg/m)

1 pound per square inch (psi) = 6.895 kilopascals (kPa)

=0.006895 megapascals (Mpa)

1 foot pound (ft-lb) = 1.3558 Joules (J)

4. Classification of tubing

The tubing is divided into flat tubing (NU), thickened tubing (EU) and integral joint tubing. Flat tubing means that the end of the pipe is directly threaded and fitted with a coupling without thickening. Thickened tubing means that after the two pipe ends are thickened outside, they are then threaded and fitted with couplings. Integral joint tubing means that one end is passed through the inner thickened car external thread, the other end is passed through the outer thickened car internal thread, and it is directly connected without a coupling.

5. The role of tubing

① Extracting oil and gas: After the oil and gas well is completed and cemented, the oil pipe is placed in the oil layer casing to extract the oil and gas to the surface.

② Water injection: When the downhole pressure is not enough, water is injected into the well through tubing.

③ Steam injection: In the process of thermal recovery of heavy oil, heat insulation tubing should be used to inject steam into the well.

④ Acidification and fracturing: In the later stage of well drilling or in order to increase the production of oil and gas wells, it is necessary to input acidification and fracturing media or solidifications into the oil and gas layer, and the media and solidifications are transported through tubing.

6. Steel grade of tubing

Tubing steel grades are: H40, J55, N80, L80, C90, T95, P110.

N80 is divided into N80-1 and N80Q. The similarity between the two is the same tensile performance, and the difference between the two is the difference in delivery state and impact performance. N80-1 is delivered in the normalized state or when the final rolling temperature is greater than the critical When the temperature is Ar3 and the tension is reduced after air cooling, the normalizing can be replaced by hot rolling, and the impact energy and non-destructive inspection are not required; N80Q must be quenched and tempered (quenched and tempered) heat treatment, and the impact energy should meet the requirements of API 5CT, and Non-destructive inspection should be carried out.

L80 is divided into L80-1, L80-9Cr and L80-13Cr. Their mechanical properties and delivery status are the same. The difference lies in the use, difficulty of production and price. L80-1 is a common type, and L80-9Cr and L80-13Cr are high corrosion resistance tubing, which is difficult to produce and expensive, and is usually used in heavy corrosion oil wells.

C90 and T95 are divided into type 1 and type 2, namely C90-1, C90-2 and T95-1, T95-2.