1. Production status of cold-drawn stainless steel heat exchange tubes in Zhide Steel Industry

2. Water pressure test of stainless steel heat exchange tubes in Zhide Steel Industry

product description:

The stainless steel heat exchange tube is one of the components of the heat exchanger, which is placed in the cylinder and used for heat exchange between the two media. In addition to bare tubes, heat exchangers can also use a variety of enhanced heat transfer tubes, such as finned tubes, threaded tubes, spiral grooved tubes, etc. When the heat transfer coefficient on both sides of the inner diameter of the tube differs greatly, the fins of the finned tube should be arranged on the side with the lower heat transfer coefficient.

Dimensions:

The commonly used dimensions of heat exchange tubes (outer diameter × wall thickness) are mainly Φ19mm×2mm, Φ25mm×2.5mm and Φ38mm×2.5mm seamless steel pipes and Φ25mm×2mm and Φ38mm×2.5mm stainless steel tubes. Standard pipe lengths are 1.5, 2.0, 3.0, 4.5, 6.0, 9.0m, etc. The use of small pipe diameter can increase the heat transfer area per unit volume, compact structure, reduce metal consumption, and increase heat transfer coefficient. It is estimated that changing the heat exchange tube of the heat exchanger with the same diameter from Φ25mm to Φ19mm can increase the heat transfer area by about 40% and save more than 20% of metal. However, the fluid resistance of the small pipe diameter is large, it is inconvenient to clean, and it is easy to block the structure. Generally, large diameter pipes are used for viscous or dirty fluids, and small diameter pipes are used for cleaner fluids.

U-shaped center distance:

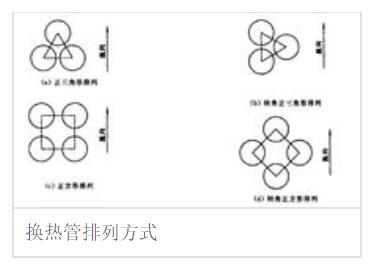

As shown in the figure, the arrangement forms of the heat exchange tubes on the tube sheet mainly include regular triangles, squares, regular triangles with corners, and squares with corners. The regular triangle arrangement can arrange the largest number of tubes on the same tube sheet area, so it is the most commonly used, but the outside of the tube is not easy to clean. In order to facilitate cleaning outside the tubes, tube bundles arranged in squares or corner squares can be used.

The center distance of stainless steel heat exchange tubes should ensure that when the tubes are connected to the tube sheet, the tube bridge (the clearance distance between two adjacent tubes) has sufficient strength and width. When the pipes need to be cleaned, there will be a channel for cleaning. The center distance of the stainless steel heat exchange tube should not be less than 1.25 times the outer diameter of the heat exchange tube. The most commonly used heat exchange tube center distance is as follows: