ASTM A53-98 fluid pipe for conveying of petroleum and gas

February 27, 2017

API 5CT J55 seamless casing pipe,OCTG casing with LTC Thread

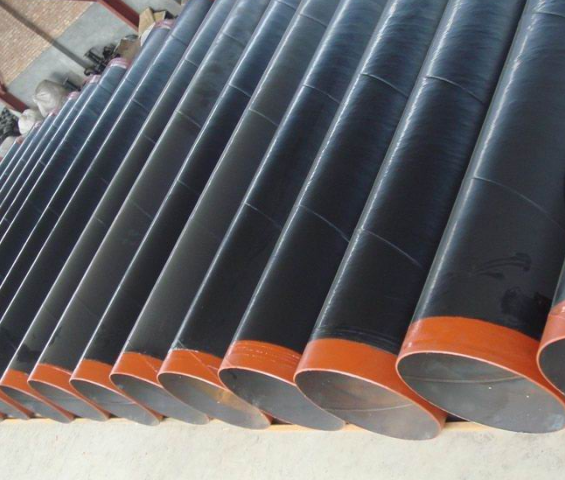

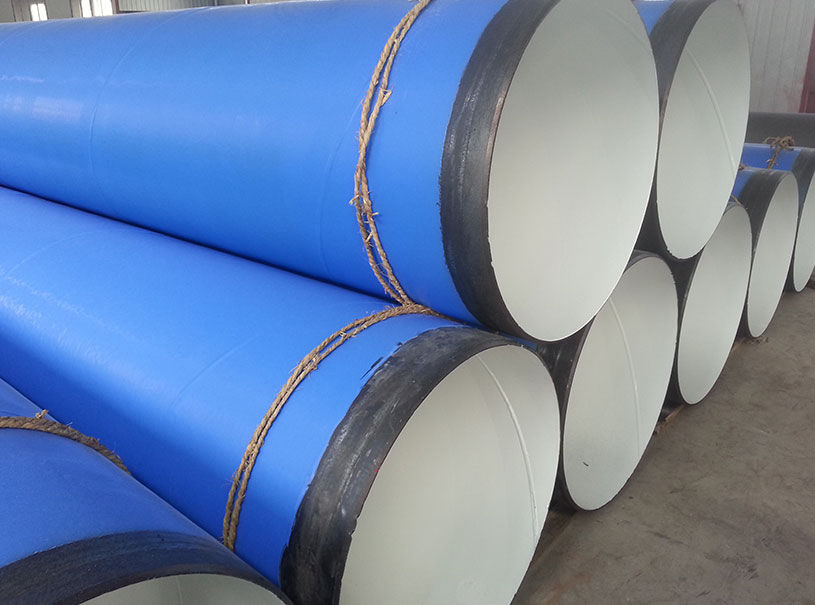

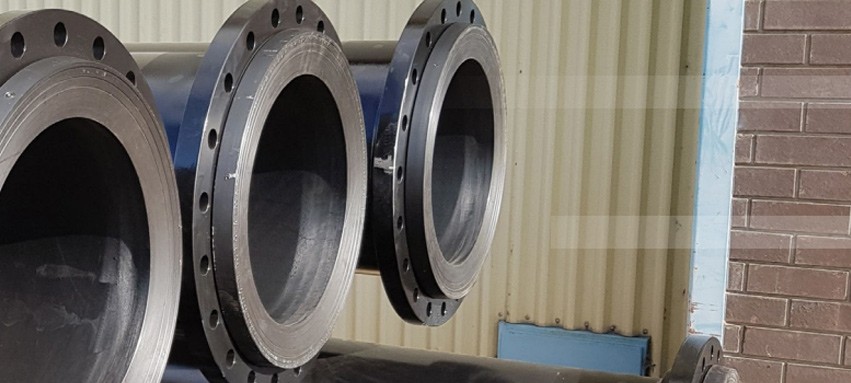

March 6, 2017Coating pipe is the pipe that is by the processing after the corrosion, which can effectively prevent or slow the steel pipe occurs in the course of transport and chemical or electrochemical reaction corrosion phenomena. Coated steel pipe can effectively prevent or slow down the corrosion of steel pipes to extend service life and reduce operating costs pipe.

The coatings are suitable for the protection of buried or submerged steel pipes at design temperatures of –40 °C up to +80 °C.

The present standard specifies requirements for coatings that are applied to longitudinally or spirally welded or seamless steel pipes and fittings used for the construction of pipelines for conveying liquids or gases.

Standard:

DIN 30670: Polyethylene coatings of steel pipes adn fittings.

DIN 30678: Polythylene coatiing of steel pipes and fittings.

SY/T0413-2002: Technical standard of polythelene coating for buried steel pipeling.

Anti-corrosion coating:

Various steel pipe external coating projects are currently implemented by our company including single-layer/double-layer FBE, 2PE,3PE,3PP and other anti-corrosion coatings with the performed standards such as DIN30670, DIN30671,DIN30678,CAN/CSA-Z245.21-M92,SY/T4013-2002 and SY/T0315-97 etc.

| Coating Type | Coating Layer | Coating thickness |

| Three layers polyethylene | Inside layer: epoxy (Green) | 2.0 -4.5mm |

| Mid layer: adhesive (White) | ||

| Outside layer:polyethylene (Black) | ||

| Two layers polyethylene | Inside layer: adhesive | 2.0 -4.5mm |

| Outside layer: polythene | ||

| Epoxy | Epoxy | 200-400um |

| Two layers epoxy | Inside layer: epoxy (Green) | 400-800um |

| Outside layer:intensity epoxy (sage green) | ||

| Three layers polyethylene | Inside layer: epoxy (Green) | 2.5 -3mm |

| Mid layer: adhesive (White) | ||

| Outside layer: polypropylene (White) |