What is Rectangular Hollow Section (RHS) ?

October 26, 2023

ASTM A500 Steel Hollow Sections for Structural

November 4, 2023Ductile Iron Pipe vs. 3PE Coating Steel Pipe: A Comparative Analysis

Introduction

In the world of piping and fluid transportation, the materials used to fabricate pipes play a crucial role in determining their performance, durability, and suitability for specific applications. This essay aims to compare and contrast two widely used types of pipes: Ductile Iron Pipe (DIP) and Three-Layer Polyethylene Coating Steel Pipe (3PE CSP). We will delve into their characteristics, applications, advantages, and disadvantages to provide a comprehensive understanding of their use in various industries.

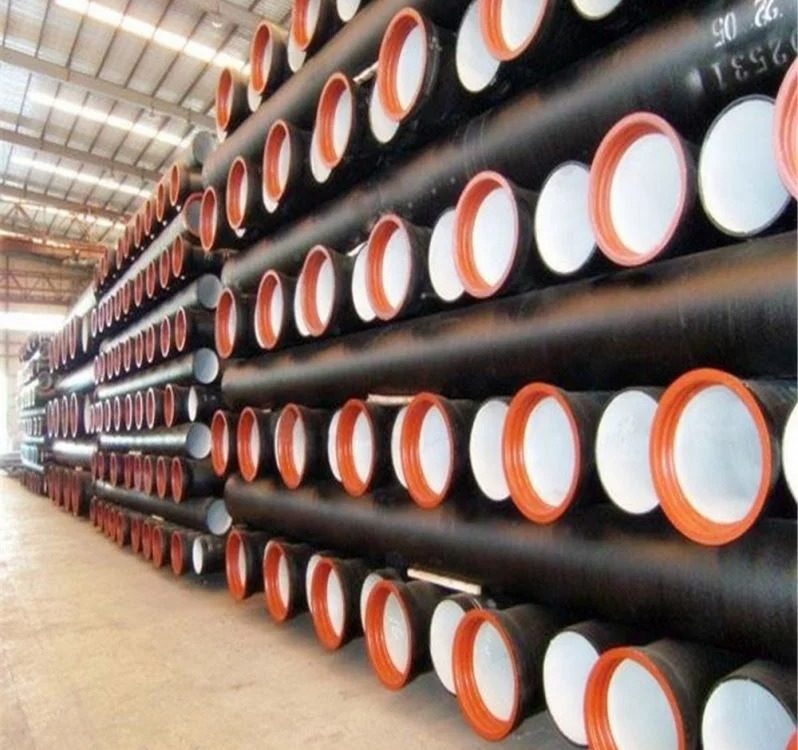

Ductile Iron Pipe: An Overview

Ductile iron pipes are a type of cast pipe made from ductile iron, a form of iron characterized by its high strength, ductility, and resistance to wear and environmental elements. These pipes are primarily used for potable water distribution, wastewater lines, and for certain gas lines.

Characteristics and Advantages

Ductile iron pipes offer several advantages:

Strength and Durability:

Ductile iron has greater mechanical strength and shock resistance than standard cast iron, which makes DIPs resistant to damage during handling, installation, and service.

Corrosion Resistance:

DIPs have good corrosion resistance, especially when they are lined with materials like cement, which further enhance their durability and lifespan.

Flexibility:

Despite their rigidity, DIPs possess a degree of deflection without suffering damage, making them suitable for use in areas subjected to ground movement or settlement.

Longevity:

With proper maintenance and monitoring, DIPs can function effectively for many decades, often over 100 years.

Disadvantages

Despite their advantages, DIPs also have certain disadvantages:

Weight:

Ductile iron is relatively heavy, making transport and installation more challenging and labor-intensive compared to lighter materials.

Cost:

DIPs can be more expensive than other pipe types, particularly for larger projects, due to their weight and the cost of the raw material.

3PE Coating Steel Pipe: An Overview

3PE Coating Steel Pipes are made from carbon steel or alloy steel pipes that are coated with a three-layer polyethylene coating (3PE). This coating is applied to provide additional protection against corrosion, abrasion, and other external factors.

Characteristics and Advantages

3PE CSPs offer several advantages:

Corrosion Resistance:

The 3-layer coating (comprising a fusion-bonded epoxy layer, an adhesive layer, and a polyethylene layer) provides excellent protection against corrosion, extending the pipe’s lifespan.

Durability:

3PE coating enhances the pipe’s resistance to chemical and physical damage, ensuring its durability in harsh environments.

Versatility:

These pipes can be used in a variety of applications, including oil and gas pipelines, water supply lines, and industrial processes.

Cost-Effectiveness:

The extended lifespan and reduced maintenance requirements of 3PE CSPs can lead to significant cost savings over time.

Disadvantages

3PE CSPs, while advantageous, have some limitations:

Coating Damage:

The coating can be damaged during handling and installation, affecting the pipe’s performance and lifespan.

Temperature Limits:

3PE coatings have temperature limitations and may not be suitable for high-temperature applications.

Comparison and Conclusion

While both DIPs and 3PE CSPs have their strengths and weaknesses, the choice between the two often depends on the specific application, project budget, and environmental conditions. Ductile iron pipes, with their strength and durability, are ideal for use in municipal water and wastewater systems. On the other hand, 3PE CSPs, with their superior corrosion resistance and versatility, are widely used in the oil and gas industry.

In conclusion, both ductile iron and 3PE-coated steel pipes play vital roles in modern infrastructure and industrial applications. By understanding their characteristics, advantages, and disadvantages, engineers and project managers can make informed decisions about the most suitable pipe type for their specific needs.

|

Standard

|

ISO2531, EN545, EN598 etc

|

|

Size

|

DN80- DN2600

|

|

Classs

|

K7, K8, K9, C40, C30, C25, etc

|

|

Length

|

6m, cut to 5.7m

|

|

NBR rubber, SBR rubber or EPDM rubber ring as per ISO4633

|

|

|

Application

|

Potable Water / Drinking Water

Sewage Water |

|

Packing

|

DN100-DN300 in bundles; DN350-DN2600 in bulk ship

|

|

Note

|

The pipe coating can be customized, such as, zinc-aluminum alloy, PU, etc.

|

Standard Offer, Drinking Water – Class 1

| DN | Prod Code | Prod Code | Pipe ClaTP | Length (mm) | Spigot OD mm (ØDE) | Socket OD mm (ØB) | Weight (Kg/m) | |||||||||

| DN80 | TPA80Q60 | C40 | 6000 | 98 | 167.0 | 12.0 | ||||||||||

| DN100 | TPB10Q60 | C40 | 6000 | 118 | 188.0 | 15.0 | ||||||||||

| DN150 | TPB15Q60 | C40 | 6000 | 170 | 242.0 | 22.0 | ||||||||||

| DN200 | TPB20Q60 | C40 | 6000 | 222 | 295.0 | 30.0 | ||||||||||

| DN250 | TPB25Q60 | C40 | 6000 | 274 | 352.0 | 42.0 | ||||||||||

| DN300 | TPB30F60 | C40 | 6000 | 326 | 409.2 | 55.5 | ||||||||||

| DN350 | TPB35G60 | C30 | 6000 | 378 | 464.2 | 69.0 | ||||||||||

| DN400 | TPB40G60 | C30 | 6000 | 429 | 516.2 | 79.5 | ||||||||||

| DN450 | TPB45G60 | C30 | 6000 | 480 | 574.2 | 94.0 | ||||||||||

| DN500 | TPB50G60 | C30 | 6000 | 532 | 629.2 | 111.0 | ||||||||||

| DN600 | TPB60G60 | C30 | 6000 | 635 | 738.5 | 150.5 | ||||||||||

| DN700 | TPB70H60* | TPB70G70 | C25/C30 | 6000/6960 | 738 | 863.0 | 188.0/217.9 | |||||||||

| DN800 | TPB80H70* | TPB80G70 | C25/C30 | 6950 | 842 | 974.0 | 213.0/267.0 | |||||||||

| DN900 | TPB90H70 | TPB90G70* | C25/C30 | 6950 | 945 | 1082.0 | 260.0/279.0 | |||||||||

| DN1000 | TPC10H70 | TPC10G70* | C25/C30 | 6960 | 1048 | 1191.0 | 311.5/334.0 | |||||||||

| DN1200 | TPC12H80 | C25 | 8190 | 1255 | 1412.5 | 461.5 | ||||||||||

| DN1400 | TPC14H80 | C25 | 8170 | 1462 | 1592.1 | 634.5 | ||||||||||

| DN1600 | TPC16H80 | C25 | 8160 | 1668 | 1815.9 | 807.5 | ||||||||||

| DN1800 | TPC18H80 | C25 | 8150 | 1875 | 2032.2 | 995.0 | ||||||||||

| DN2000 | TPC20H80 | C25 | 8130 | 2082 | 2259.0 | 1210.0 | ||||||||||

Standard Offer, Drinking Water – Class 2

| DN | Prod Code | Pipe ClaTP | Length (mm) | Spigot OD mm (øDE) | Socket OD mm (øDE) | Weight (Kg/m) | ||||||||||

| DN80 | 189486 | C40 | 5500 | 98 | 167.0 | 15.0 | ||||||||||

| DN100 | 189509 | C40 | 5500 | 118 | 188.0 | 17.5 | ||||||||||

| DN150 | 189515 | C40 | 5500 | 170 | 242.0 | 26.0 | ||||||||||

| DN200 | 197942 | C40 | 5500 | 222 | 295.0 | 35.0 | ||||||||||

| DN250 | 189518 | C40 | 5500 | 274 | 352.0 | 45.5 | ||||||||||

| DN300 | 189519 | C40 | 5500 | 326 | 409.2 | 57.0 | ||||||||||

| DN350 | TPB35G55EC | C30 | 5500 | 378 | 464.2 | 69.0 | ||||||||||

| DN400 | TPB40G55EC | C30 | 5500 | 429 | 516.2 | 79.5 | ||||||||||

| DN450 | TPB45G55EC | C30 | 5500 | 480 | 574.2 | 94.0 | ||||||||||

| DN500 | TPB50G55EC | C30 | 5500 | 532 | 629.2 | 111.0 | ||||||||||

| DN600 | TPB60G55EC | C30 | 5500 | 635 | 738.5 | 150.5 | ||||||||||

| DN700 | TPB70N55EC | C30 | 5500 | 738 | 863.0 | 188.0 | ||||||||||

Standard offer, Sewer

| DN | Integral Plus Prod code | Integral Prod code | Length (mm) | Spigot OD mm (øDE | Socket OD mm (øDE) | Weight (Kg/m) | |

| DN80 | 205667 | TPA80S60 | 6000 | 98 | 167.0 | 13.0 | |

| DN100 | 205669 | TPB10S60 | 6000 | 118 | 188.0 | 16.0 | |

| DN150 | 205670 | TPB15S60 | 6000 | 170 | 242.0 | 23.5 | |

| DN200 | 205711 | TPB20S60 | 6000 | 222 | 295.0 | 31.0 | |

| DN250 | 205718 | TPB25S60 | 6000 | 274 | 352.0 | 40.5 | |

| DN300 | 205712 | TPB30S60 | 6000 | 326 | 409.2 | 51.0 | |

| DN350 | 205719 | TPB35S60 | 6000 | 378 | 464.2 | 66.5 | |

| DN400 | 205720 | TPB40S60 | 6000 | 429 | 516.2 | 78.0 | |

| DN450 | 205731 | TPB45S60 | 6000 | 480 | 574.2 | 92.5 | |

| DN500 | 205732 | TPB50S60 | 6000 | 532 | 629.2 | 106.5 | |

| DN600 | 205733 | TPB60S60 | 6000 | 635 | 738.5 | 138.0 | |

| DN700 | 205735 | TPB70E69 | 6000/6950 | 738 | 863.0 | 201.0 | |

| DN800 | 206666 | TPB80E69 | 6950 | 842 | 974.0 | 243.5 | |

| DN900 | TPB90E69 | 6950 | 945 | 1082.0 | 291.5 | ||

| DN1000 | TPC10E69 | 6960 | 1048 | 1191.0 | 343.0 | ||

| DN1200 | TPC12N79 | 8190 | 1255 | 1412.5 | 507.5 | ||

| DN1400 | TPC14N80 | 8170 | 1462 | 1592.1 | 679.0 | ||

| DN1600 | TPC16N80 | 8160 | 1668 | 1815.9 | 851.5 | ||

| DN1800 | TPC18N80 | 8150 | 1875 | 2032.2 | 1036.5 | ||

| DN2000 | TPC20N80 | 8130 | 2082 | 2259.0 | 1242.0 | ||

Ductile iron pipe refers to the pipe made by high-speed centrifugal casting of centrifugal ductile iron machine after the addition of spheroidizing agent with cast iron of more than 18, referred to as ductile iron pipe, ductile iron pipe and ductile cast pipe, etc. Mainly used for the transmission of tap water, is the ideal choice of tap water pipeline materials.