Nickel 200 (UNS N02200) Alloy Tubes

September 26, 2025

API 5L X70 Line Pipe Production Capability Overview

October 4, 2025Carbon Steel Pipe Caps: An Authoritative Guide to Engineering, Manufacturing, and Applications

Introduction: A Crucial Component in Industrial Piping Systems

Carbon steel pipe caps, also known as heads or plugs, are crucial components in industrial piping systems used to permanently or temporarily close a pipe opening.[1] Their role extends far beyond a simple plugging function. They are essential for maintaining the integrity and leak-tightness of a piping system, effectively preventing the leakage of liquid or gaseous media, and protecting the interior from foreign object contamination during construction or operation.[1] Furthermore, during hydrostatic or pneumatic pressure testing, a pipe cap plays a decisive role by sealing the system, allowing it to withstand the test pressure.[1]

Carbon steel is the preferred material for manufacturing these components because it provides a perfect balance of strength, durability, and cost-effectiveness.[2, 3] Its superior mechanical properties are particularly crucial when facing demanding service conditions like high pressure and temperature, making it an indispensable choice for critical industries such as oil and gas, petrochemical, and power generation. A seemingly simple pipe cap is more than just a plug; it is a structural component engineered to withstand a full spectrum of operational stresses, from internal pressure to external environmental factors. This functional demand directly dictates its engineering, manufacturing, and quality standards, which form the foundation of its reliable performance. This cause-and-effect relationship demonstrates that the intended function of the cap (e.g., for pressure testing or sealing) determines the material, manufacturing, and testing standards that must be met, a key element of an expert analysis rather than a simple product description.

Chapter One: Analysis of Cap Uses and Functions

1.1 Pipe Cap Types Classified by Connection Method

Carbon steel pipe caps are available in several main types based on how they connect to the pipe, with each type designed to meet specific application needs and operational pressure ratings.

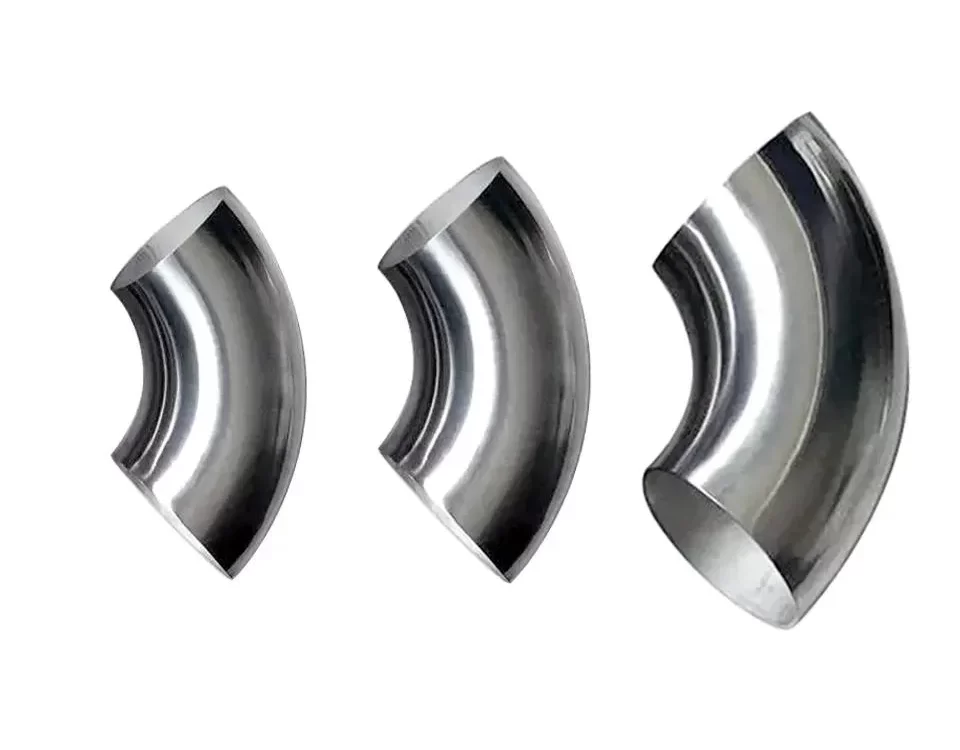

- Butt-Weld Caps: These are factory-made wrought fittings designed for permanent connection to the end of a pipe by butt welding.[1, 4] They are typically used in high-pressure applications where a complete seal is critical and are governed by industry standards such as ASME B16.9.[1, 4] The manufacturing of butt-weld caps often involves a seamless process, where the cap is stamped from a single piece of steel, which minimizes potential weak points from welded joints.[5]

- Socket-Weld Caps: These caps are connected by inserting the pipe into a recessed area (the “socket”) of the cap before welding.[4] This method is detailed in ASME B16.11 and is often used for high-pressure applications up to Class 9000.[1, 4]

- Threaded Caps: These caps have internal threads designed to screw onto the external threads of a pipe end.[1, 6] They provide a tight seal for liquids or gases and are also governed by ASME B16.11, typically for lower pressure ratings such as Class 2000, 3000, and 6000.[1, 6] The threads can be tapered (such as NPT, BSP) or straight.[5, 6]

The choice among butt-weld, socket-weld, and threaded connections directly depends on the required pressure rating and permanence of the connection. Butt-weld connections offer the highest strength and most permanent seal, making them the preferred choice for critical high-pressure systems. In contrast, threaded caps provide a temporary or semi-permanent seal, suitable for systems that may need future expansion or maintenance, such as during pressure testing.[1] The process of manufacturing butt-weld caps often involves forming a seamless product from a single piece of steel [5], which minimizes potential weak points at weld seams. In contrast, socket-weld and threaded fittings are typically made using the forging process.[7] Forging imparts a fine-grained structure and high mechanical strength to the material [8], which is essential for these connection types as they must withstand complex stresses from the joint (socket-weld) or threads (threaded). This suggests a nuanced manufacturing strategy: seamless stamping for permanent, high-integrity connections, and forging for other types to achieve the necessary strength. The entire manufacturing process, from raw material selection to final inspection, reflects the rigorous standards that the industry follows. Adherence to dimensional standards such as ASME B16.9 and B16.11 [1, 4, 9] ensures that fittings from different manufacturers are interchangeable and reliable, which is a critical factor for large infrastructure projects.

Technical parameters

| Nominal diameter | End outer diameter | Distance from back face to end face | ||||

| DN | NPS | Series A | Series B | E | Ultimate thickness T at length E | E1 |

| 15 | 1/2 | 21.3 | 18 | 25 | 4.57 | 25 |

| 20 | 3/4 | 26.9 | 25 | 25 | 3.81 | 25 |

| 25 | 1 | 33.7 | 32 | 38 | 4.57 | 38 |

| 32 | 1.1/4 | 42.4 | 38 | 38 | 4.83 | 38 |

| 40 | 1.1/2 | 48.3 | 45 | 38 | 5.08 | 38 |

| 50 | 2 | 60.3 | 57 | 38 | 5.59 | 44 |

| 65 | 2.1/2 | 76.1(73) | 76 | 38 | 7.11 | 51 |

| 80 | 3 | 88.9 | 89 | 51 | 7.62 | 64 |

| 90 | 3.1/2 | 101.6 | 64 | 8.13 | 76 | |

| 100 | 4 | 114.3 | 108 | 64 | 8.64 | 76 |

| 125 | 5 | 139.7 | 133 | 76 | 9.65 | 89 |

| 150 | 6 | 168.3 | 159 | 89 | 10.92 | 102 |

| 200 | 8 | 219.1 | 219 | 102 | 12.7 | 127 |

| 250 | 10 | 273 | 273 | 127 | 12.7 | 152 |

| 300 | 12 | 323.9 | 325 | 152 | 12.7 | 178 |

| 350 | 14 | 355.6 | 377 | 165 | 12.7 | 191 |

| 400 | 16 | 406.4 | 426 | 178 | 12.7 | 203 |

| 450 | 18 | 457.2 | 478 | 203 | 12.7 | 229 |

| 500 | 20 | 508 | 529 | 229 | 12.7 | 254 |

| 550 | 22 | 559 | 254 | 12.7 | 254 | |

| 600 | 24 | 610 | 630 | 267 | 12.7 | 305 |

| 650 | 26 | 660 | 267 | 1 | 1 | |

| 700 | 28 | 711 | 720 | 267 | 1 | |

| 750 | 30 | 762 | 267 | 1 | ||

| 800 | 32 | 813 | 820 | 267 | ||

| 850 | 34 | 864 | 267 | 1 | ||

| 900 | 36 | 914 | 920 | 267 | 1 | |

| 950 | 38 | 965 | 305 | 1 | ||

| 1000 | 40 | 1016 | 1020 | 305 | ||

| 1050 | 42 | 1067 | 305 | |||

| 1100 | 44 | 1118 | 1120 | 343 | ||

| 1150 | 46 | 1168 | 343 | |||

| 1200 | 48 | 1220 | 1220 | 343 | ||

| Note: Height E is applicable when T does not exceed the value in brackets, otherwise E1 height should be used. | ||||||

1.2 Overview of Common Shapes and Designs

In addition to connection types, pipe caps are available in a variety of shapes and designs to meet different functional and aesthetic needs. Pipe caps come in various shapes, including hemispherical, oval, round, square, and rectangular.[5, 6]

- Round Caps: The most common type, round caps may feature a flange for easy removal and added protection; a slotted head for screwdriver installation; or a knurled or faceted head for easy manual installation and removal, which are typical characteristics of threaded caps and plugs.[5, 6]

- Square/Rectangular Caps: These are specifically designed for square pipe applications, such as for fencing or furniture manufacturing. The key dimensional considerations are the length and width.[5, 6]

Chapter Two: The Cornerstone Material: ASTM A234 WPB

2.1 Detailed Chemical Composition and Properties

Carbon steel pipe caps are predominantly manufactured from the ASTM A234 WPB grade, a standard specification for wrought carbon and alloy steel fittings for moderate and elevated temperature service.[10, 11] The “WPB” designation stands for “Wrought Grade B,” which is a specific grade within this standard. The letter ‘W’ signifies weldable, ‘P’ stands for pressure, and ‘B’ refers to its grade, which relates to its minimum yield strength.[11]

The chemical composition of ASTM A234 WPB is precisely controlled to ensure a balance of strength, durability, and weldability. The following table lists the key elements and their percentages.[10, 11, 12] The carbon content is kept relatively low (0.30% max) to ensure good weldability, a crucial requirement for fittings designed to be welded.[2, 10]

2.2 Key Mechanical Properties Crucial for High-Performance Service

The mechanical properties of ASTM A234 WPB are what enable it to withstand high-stress, high-heat, and high-pressure environments without failure.[10]

- Yield Strength: A minimum yield strength of 240 MPa (35 ksi) [10, 11] or 32 ksi [13] represents the point at which the material begins to deform plastically. This value provides a safety margin for standard pressure piping systems.[10, 11, 14]

- Tensile Strength: Ranging from 415-585 MPa (60-85 ksi), the tensile strength is the maximum load the material can handle before fracturing.[10, 11, 13] This ensures it can handle significant stress in demanding environments.[10]

- Elongation: A minimum elongation of 22% indicates good ductility and flexibility, allowing the material to deform under stress without fracturing, a critical safety feature in high-pressure systems.[10, 15]

There may be slight variations in reported mechanical properties (e.g., yield strength of 35 ksi [11] or 32 ksi [13]) within the ASTM A234 standard. This is not a contradiction but rather a reflection of the tolerances allowed by the standard. These differences highlight the importance of obtaining a certified Material Test Certificate (MTC) to ensure that a specific batch of products meets the required specifications.[12] This nuanced understanding of material standards and the emphasis on quality control is a hallmark of true insight into industry operations.

2.3 The Role of Heat Treatment in Enhancing Performance

Heat treatment is a critical step in the manufacturing of ASTM A234 WPB fittings, designed to achieve the desired mechanical properties. The specific process depends on the final forming temperature.[16, 17]

- Hot-Formed Fittings: If the final forming operation is completed between 1150°F (620°C) and 1800°F (980°C), no additional heat treatment is required, and they can be cooled in still air.[16, 17] However, if the temperature exceeds 1800°F, subsequent annealing, normalizing, or normalizing and tempering must be performed.[17]

- Cold-Formed Fittings: For fittings formed at temperatures below 1150°F (620°C), they must be normalized or stress-relieved between 1100°F (595°C) and 1275°F (690°C) to relieve internal stresses and restore mechanical properties.[16, 17]

It’s worth noting that while ASTM A234 WPB is the most common material, there is a clear trend in modern sectors like oil and gas pipelines towards “High Yield” materials like ASTM A860 and WPHY grades.[14] These materials offer higher minimum yield strengths (42-70 ksi), allowing for higher pressures, increased fluid flow, and longer service life.[14] This shows that while WPB is the industry workhorse, the market is evolving towards more specialized, higher-performance alternatives for the most demanding applications.

Chapter Three: From Raw Material to Finished Product: The Manufacturing Journey

3.1 Main Manufacturing Methods

The production of carbon steel pipe caps involves several key manufacturing methods, each chosen based on the desired shape, strength, and production volume.[8]

- Forging: In this process, the metal is heated to a plastic state and then shaped under high pressure using dies.[8] Forging creates components with high mechanical strength, durability, and a refined grain structure, making it ideal for high-pressure applications.[7, 8]

- Stamping: This method uses a stamping press to cut and shape metal sheets into the desired cap form. It is highly efficient for mass production and ensures dimensional consistency.[8, 18]

- Casting: Casting involves pouring molten metal into a mold where it cools and solidifies. This is suitable for producing complex designs and can use a wide variety of materials, but the resulting caps may have lower mechanical properties than forged or welded ones.[8]

- Welding: Welded caps are made by joining two flat metal plates, which offers versatility in size and shape. However, welded caps may have potential weak points at the joints, making them less suitable for high-stress applications than forged caps.[8]

3.2 In-depth Exploration of the Forging Process

The forging process for pipe fittings is a multi-step journey.[7]

- Raw Material Selection: High-quality carbon steel billets or plates are chosen, and their chemical composition is verified to meet ASTM standards.[7, 10]

- Heating and Forging: The raw material is heated in a furnace to a temperature where it is malleable, then shaped in a forging press using specialized dies. Common forging methods include:

- Open-Die Forging: The metal is shaped by repeated blows from a hammer and is not fully enclosed by the die. This method is used for producing large, simple shapes and relies on the operator’s skill.[7]

- Closed-Die Forging: The metal is placed between two pre-machined dies and shaped under pressure, offering precise control for smaller, more intricate fittings.[7]

- Finishing: After forging, any excess material is trimmed, and the fitting may undergo further machining to achieve specific features.[7]

The manufacturing method is not an arbitrary choice but a direct consequence of the product’s intended application. Forged caps are the preferred choice for high-pressure, high-stress environments due to their superior integrity.[7, 8] In contrast, stamped caps are better suited for high-volume, low-cost applications where strength is not the primary driver. This is a fundamental engineering logic that links a manufacturer’s process choice directly to the product’s market positioning. The entire manufacturing process, from raw material selection to final inspection, demonstrates the rigorous standards followed by the industry. Adherence to dimensional standards like ASME B16.9 and B16.11 [1, 4, 9] ensures that fittings from different manufacturers are interchangeable and reliable, which is a critical factor for large-scale infrastructure projects.

Chapter Four: Ensuring Integrity and Reliability: Quality Assurance and Standards

4.1 The Importance of Non-Destructive Testing (NDT)

Non-destructive testing is a cornerstone of quality assurance in the manufacturing of pipe fittings. It provides accurate insight into the condition of a material without causing any damage to the component, which is crucial for safety-critical applications in oil and gas, power generation, and other high-pressure industries.[19]

4.2 Overview of Main Non-Destructive Testing Methods

- Radiographic Testing (RT): This method uses X-ray or gamma energy to detect internal flaws within welds and castings, such as porosity or incomplete fusion.[19]

- Ultrasonic Testing (UT): UT sends high-frequency sound waves into a material to locate internal flaws, measure thickness, and detect cracks or voids. It only requires access to one side, making it ideal for in-service inspections.[19, 20]

- Magnetic Particle Inspection (MPI): Used on ferromagnetic materials like carbon steel, MPI magnetizes the component and applies iron particles to reveal surface and near-surface flaws like fatigue cracks or forging defects.[19]

- Liquid Penetrant Testing (PT): A dye is applied to the surface, which is drawn into open defects by capillary action. A developer then highlights these surface-breaking flaws. This method is effective on both magnetic and nonmagnetic materials.[19]

- Positive Material Identification (PMI): PMI uses X-ray fluorescence to verify the chemical composition of an alloy on-site without damaging the part. This ensures the correct material grade has been used, preventing critical failures from material mix-ups.[19]

The widespread use of NDT and material verification standards is a direct response to the potentially catastrophic consequences of failure in high-pressure systems. It is not merely a quality control step but a risk mitigation strategy. By guaranteeing a product’s integrity through certified testing, a manufacturer builds a reputation for reliability and safety, which is essential for securing contracts in high-risk industries. The detailed heat treatment requirements for ASTM A234 WPB [17] are directly linked to the necessity of NDT. For example, cold-formed fittings must be stress-relieved or normalized. Without NDT methods like ultrasonic or visual inspection, there would be no way to verify if the heat treatment was successful or if it introduced internal defects or surface cracks. This creates a tight, cyclical relationship between engineering specifications, the manufacturing process, and quality assurance, highlighting the manufacturer’s expertise at every stage.

Chapter Five: Key Applications and Strategic Advantages

5.1 Industrial Sectors Where Carbon Steel Pipe Caps Are Crucial

Carbon steel pipe caps are indispensable in many industrial sectors, valued for their superior strength, durability, and cost-effectiveness.[21]

- Oil and Gas: Extensively used in pipelines that transport crude oil, natural gas, and other hydrocarbons, where they must withstand high pressure and temperature.[2, 10, 21]

- Power Plants: Critical for connecting pipes in steam and water systems.[21]

- Petrochemical Industry: Key components in systems handling a wide range of fluids and chemicals.[10, 21]

- Other Applications: They are also widely used in water treatment, mining, food processing, and shipbuilding.[5, 21]

5.2 Economic and Performance Advantages of Carbon Steel

- Cost-Effectiveness: Carbon steel is significantly cheaper than its stainless steel or alloy steel counterparts, making it the most cost-effective choice for large-scale projects with budget constraints.[2, 3, 22, 23]

- Superior Strength and Durability: The high carbon content provides excellent mechanical properties, allowing the caps to withstand significant stress, strain, and wear without deforming or failing. This robustness is the key reason for their selection in high-pressure, high-temperature environments.[2]

- Ease of Fabrication: Carbon steel is easier to weld, cut, and shape than stainless steel, which means lower labor costs, faster installation times, and greater flexibility for on-site modifications.[2, 3, 21]

The true value of carbon steel lies in its optimal cost-to-performance ratio. While other materials may excel in a single property (e.g., corrosion resistance), carbon steel provides a robust combination of high strength and affordability, making it the default choice for the vast majority of industrial applications.[22] In industries like oil and gas, where the piping infrastructure is immense, material cost is a major driving factor. Unless the conveyed media is highly corrosive, it is economically unfeasible to choose a more expensive material like stainless steel for the entire pipeline system.[3] The combination of strength to handle extreme pressures and low cost makes carbon steel a strategic choice, proving that the most “advanced” material is not always the most practical or effective solution.

Chapter Six: Comparative Analysis: Carbon Steel vs. Other Materials

6.1 Carbon Steel vs. Stainless Steel

- Composition: The key difference is the presence of chromium (minimum 10.5%) in stainless steel, which forms a passive, corrosion-resistant layer of chromium oxide when exposed to oxygen. Carbon steel lacks this layer and is thus prone to rust.[3, 22]

- Corrosion Resistance: Stainless steel is the undisputed “corrosion champion,” making it ideal for marine environments, chemical processing, and other corrosive applications.[3, 22] Carbon steel requires protective coatings (e.g., galvanization or epoxy) to resist corrosion, which adds to long-term costs and maintenance.[22]

- Cost and Fabrication: Carbon steel holds the cost advantage and is easier to weld and fabricate. While stainless steel is also weldable, its chromium content presents different challenges.[2, 3, 22]

6.2 Carbon Steel vs. Alloy Steel

- Composition: Alloy steel contains additional elements like chromium, nickel, and molybdenum to enhance specific properties.[11, 23]

- Properties: Alloy steel offers superior strength, hardness, and wear resistance. It can also be formulated for enhanced corrosion and heat resistance, making it suitable for more demanding, specialized applications in oil and gas and aerospace.[23, 24]

- Cost: Alloy steel is significantly more expensive than carbon steel, positioning it as a premium material for high-stress, specialized environments.[23]

6.3 Carbon Steel vs. Ductile Iron

- Composition and Structure: Ductile iron is a type of cast iron where the high carbon content is treated to form spherical graphite nodules, which makes it more malleable and ductile than traditional cast iron.[25, 26, 27]

- Properties: Ductile iron is stronger and more corrosion-resistant than carbon steel. It also has better machinability and can be cast into complex shapes.[25, 27, 28]

- Applications and Cost: Due to its strength and corrosion resistance, ductile iron is commonly used for municipal water systems and infrastructure.[27, 29, 30] It is more expensive than carbon steel, and carbon steel is easier to weld.[25, 28]

This comparative analysis provides engineers with a strategic decision-making matrix. The choice of material is a trade-off between initial cost, long-term maintenance, and performance requirements. For standard vent or steam pipes in non-corrosive environments, carbon steel is the most logical and cost-effective choice. For a high-pressure line carrying saltwater, the higher upfront cost of stainless steel is justified by the long-term savings on corrosion management.[3, 22] The existence of these different materials reinforces carbon steel’s market position as a foundational, versatile workhorse for the industry.

Chapter Seven: Technical Data and Specifications

This chapter provides a detailed, comprehensive table that consolidates key technical parameters, serving as a quick reference for engineers and purchasing professionals. The data is directly sourced from research materials and presented in a professional table format.

Technical Specifications of ASTM A234 WPB Carbon Steel Pipe Caps

| Property | Value/Specification | Source |

|---|---|---|

| Chemical Composition | ||

| Carbon (C) | 0.30% maximum | [10, 11] |

| Manganese (Mn) | 0.29% – 1.06% | [11, 12] |

| Phosphorus (P) | 0.05% maximum | [10, 11] |

| Sulfur (S) | 0.05% maximum | [10, 11] |

| Silicon (Si) | 0.10% minimum | [11, 12] |

| Molybdenum (Mo) | 0.15% maximum | [12] |

| Chromium (Cr) | 0.40% maximum | [12] |

| Mechanical Properties | ||

| Tensile Strength | 415-585 MPa (60-85 ksi) | [10, 13] |

| Yield Strength | 240 MPa minimum (35 ksi) | [10, 11] |

| Elongation | 22% minimum | [10] |

| Hardness | 197 HB maximum | [10] |

| Dimensional Standards (ASME B16.9) | ||

| Nominal Pipe Size (NPS) | 1/2″ to 48″ | [1, 9] |

| Outside Diameter at Bevel | 21.3 mm to 1219 mm | [9] |

| Length E | 25 mm to 343 mm | [9] |

| Limiting Wall Thickness | 3.81 mm to 12.70 mm | [9] |

The value of this table lies in its ability to consolidate disparate technical data into a single, easy-to-understand reference. It provides the precise, quantitative information that engineers and purchasing professionals need to make informed decisions. Its accuracy and direct link to industry standards establish its credibility and authority.

Conclusion: The Enduring Value of Carbon Steel Pipe Caps in Modern Industry

A central finding of this report is that carbon steel pipe caps are far more than simple fittings. They are carefully engineered components whose design, material, and manufacturing are strictly governed by international standards to ensure reliability and safety.[1, 7, 8] The choice of carbon steel is a strategic one, as it offers the optimal balance between strength, durability, and cost-effectiveness, making it the default standard for the vast majority of industrial applications.[2, 22]

Despite the emergence of new materials and technologies, the foundational role of carbon steel pipe caps remains irreplaceable in many sectors. Their proven reliability and economic advantages ensure that they will continue to be a vital component of modern industrial infrastructure for the foreseeable future.