l555m steel pipeline (New technological inventions) with excellent low temperature toughness and manufacturing method thereof

September 17, 2023

Welded Spiral Steel Pipes – GOST 8696

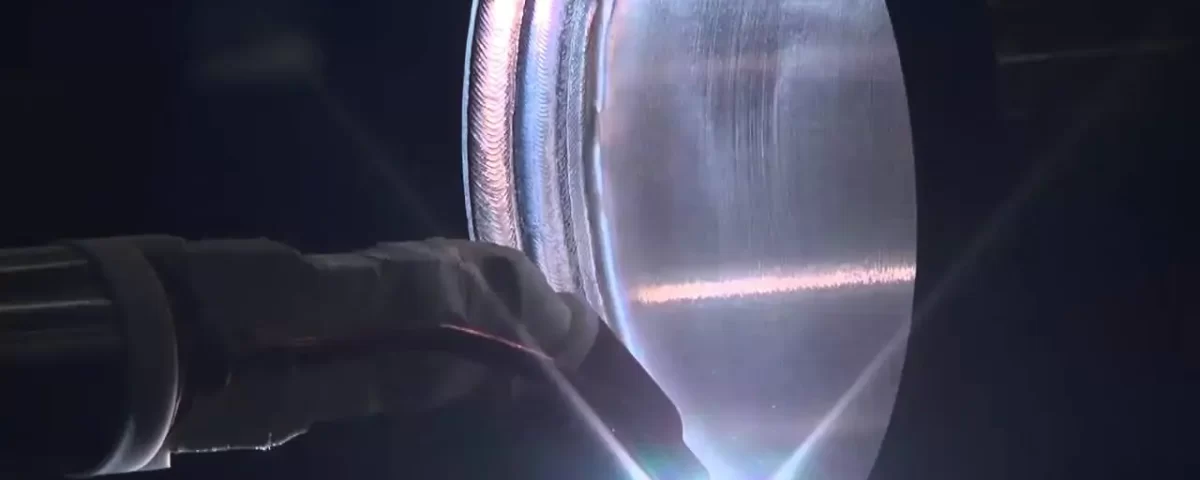

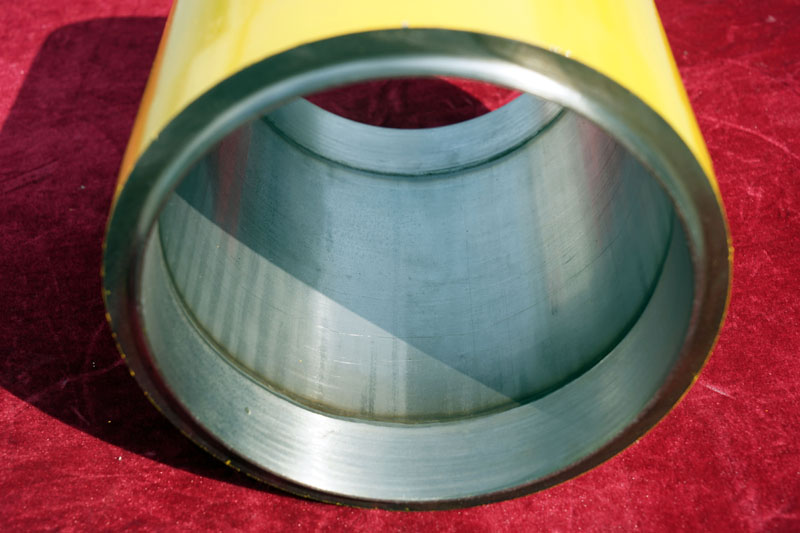

September 23, 2023Weld Overlay on Steel Pipe

Weld overlay, also known as cladding or hardfacing, is a process where one or more metals are joined together via welding to the surface of a base metal (substrate) as a layer. This is usually done to improve the base metal’s durability, corrosion resistance, or other properties. In the case of a steel pipe, a weld overlay can be used to enhance the pipe’s resistance to wear and corrosion.

Process

A common method for weld overlay is a process called Submerged Arc Welding (SAW). In this process, a welding arc is submerged in a flux, which prevents atmospheric contamination. Other methods can include Gas Metal Arc Welding (GMAW), Gas Tungsten Arc Welding (GTAW), and Plasma Transferred Arc Welding (PTAW).

The weld overlay process involves the following steps:

- Preparation: The surface of the steel pipe is cleaned and prepared. Any contaminants, rust, or old coatings are removed to ensure a clean surface for welding.

- Welding: The selected filler material (which could be a different type of steel or other metal) is melted and deposited onto the surface of the steel pipe. The filler material forms a bond with the base metal.

- Cooling: The newly formed overlay is allowed to cool and solidify.

- Inspection: The final product is inspected for any defects or inconsistencies.

Advantages of Weld Overlay

- Corrosion resistance: By selecting a corrosion-resistant material as the overlay, the steel pipe can better withstand harsh environments.

- Abrasion resistance: The overlay can be chosen for its ability to resist wear and tear, enhancing the lifespan of the steel pipe.

- Heat resistance: Certain overlays can improve the high-temperature resistance of the steel pipe.

- Restoration: Weld overlay can be used to restore damaged or worn-out sections of a steel pipe, saving the cost of replacing the entire pipe.

Disadvantages of Weld Overlay

- Cost: Weld overlay can be a costly process, particularly if expensive filler materials are used.

- Warpage: The heat from the welding process can cause distortion or warpage in the steel pipe.

- Complexity: The process requires skilled welders and careful control to achieve a successful overlay.

Overall, the weld overlay process can significantly improve the performance and lifespan of a steel pipe, making it a valuable technique in many industrial applications.

What are some common filler materials used in weld overlay for steel pipes?

Base materials that can be weld overlay:

| Base material | standard |

| Steel Pipe | API LX series, API 5L Gr.B series, ASTM A53 B series, ASTM A106 series, ASTM A333 GR 6 series, ASTM A312 series, ASTM 671 series, ASTM 691 series |

| flange | ASTM A105 series, ASTM A350 series, ASTM A694 series, ASTM A182 series, API K series, ASTM A29 4140 series, etc. |

| Pipe fittings | ASTM A234 series, ASTM A420 series, ASTM A860 series, ASTM A516 series, etc. |

Corrosion-resistant materials that can weld overlay:

| Welding consumables | Trademark |

| Stainless steel | 304, 316L, 321, 347, 310S, 904L, 309L, 317L, S31254, etc. |

| F | 625, 825, C22, C276, 400, K500, etc. |

| Copper-nickel alloy | B10(C70600), B30(C70500), etc. |

| Bronze and copper-nickel alloys | Aluminum bronze, tin bronze, silicon bronze, nickel aluminum bronze, B10 (C70600), B30 (C70500), etc. |

| Duplex steel | S31803, S32750, S32760, etc. |

| Iron-based alloy | TP405, TP409, TP410, etc. |

| Titanium | TA1、TA2、TA3等 |

| Cobalt based alloy Stellite | 6, 12, 21, etc. |

Implementation standards:

| API Spec 5LD | | Specification for corrosion-resistant alloy composite steel pipes covered or lined |

| ANSI/API Spec 6A | | Wellhead and Christmas Tree Equipment Specifications |

| ISO 15614-7 | | Metal Material Welding Process Specification and Qualification-Welding Process Qualification Experiment Part 7: Surfacing Welding |

| SYT 6623-2012 | | Specification for corrosion-resistant alloy composite steel pipes covered or lined |

| NB/T47014 | | Welding process qualification standards for pressure equipment (including corrosion-resistant surfacing welding process assessment, composite metal material welding process assessment) |

| ISO 3834-2 | | Quality requirements for fusion welding of metallic materials – Part 2: Complete quality requirements |

| NACE MRO175/ISO 15156 | | Oil and gas industry-Hydrogen sulfide-containing environmental materials used in oil and gas extraction |

| API PR 582 | | Guide to Welded Pipes for the Chemical, Oil and Gas Industry |

| DNV-OS-F101 | | Subsea pipeline system specifications |

| API 17D | | Design and operation of subsea production systems – subsea wellhead and Christmas tree design |

| API 6D | | Specifications for pipeline and duct valves |

| SY/T 7464-2020 | | Corrosion-resistant alloy bimetal composite pipe welding and non-destructive testing technology |