Iraqi customers purchase list: DUCTILE IRON PIPE

April 11, 2018

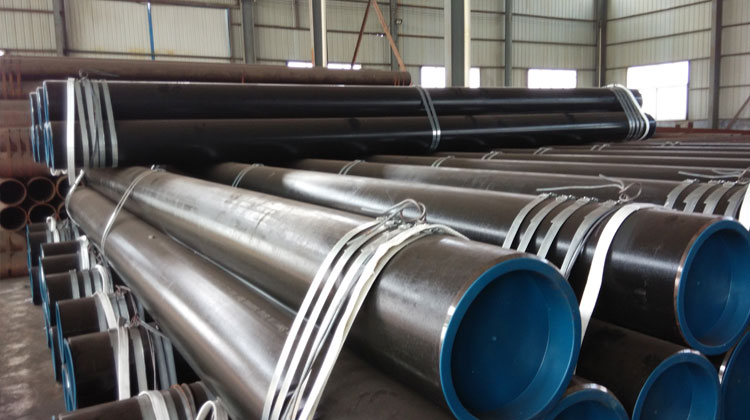

ASTM A53 GR.B STEEL PIPES stock with lower cost than market

April 17, 2018Different types of steel are produced according to the mechanical and physical properties required for their application. Various grading systems are used to distinguish steels based on these properties, which include density, elasticity, melting point, thermal conductivity, strength, and hardness (among others). To make different steels, manufacturers vary the type and quantity of alloy metals, the production process, and the manner in which the steels are worked to produce particular products.

-

- Carbon Steels

- Alloy Steels

- Stainless Steels

- Tool Steels

Properties of Carbon Steels

Carbon steels are alloys made from a combination of iron and carbon. By varying the percentage of carbon, it is possible to produce steel with a variety of different qualities. In general, the higher the carbon level the stronger and more brittle the steel.

Low carbon steel is sometimes called “wrought iron.” It is easy to work and may be used for decorative products such as fencing or lamp posts. Medium carbon steel is very strong and is often used for large structures such as bridges. High carbon steel is used mainly for wires. Ultra high carbon steel, also called “cast iron,” is used for pots and other items. While it is a very hard steel, it is also quite brittle.

Alloy Steels

Alloy steels contain alloying elements (e.g. manganese, silicon, nickel, titanium, copper, chromium, and aluminum) in varying proportions in order to manipulate the steel's properties, such as its hardenability, corrosion resistance, strength, formability, weldability or ductility.

Applications for alloys steel include pipelines, auto parts, transformers, power generators and electric motors.

Properties of Alloy Steels

ALLOY STEEL PIPE FITTINGS

Alloy steels are so named because they are made with a small percentage of one or more metals besides iron. The addition of alloys changes the properties of steels. For example, steel made from iron, chromium, and nickel produces stainless steel. The addition of aluminum can make steel more uniform in appearance.

Properties of Stainless Steels

Stainless steels contain between 10-20% chromium, making the steel extremely resistant to corrosion (rusting). When a steel contains over 11% chromium, it is about 200 times more resistant to corrosion as steels that do not contain chromium. There are three groups of stainless steels:

- Austenitic steels, which are very high in chromium, also contain small amounts of nickel and carbon. These are very commonly used for food processing and piping. They are valued, in part, because they are non-magnetic.

- Ferritic steels contain about 15% chromium but only trace amounts of carbon and metal alloys such as molybdenum, aluminum, or titanium. These steels are magnetic, very hard and strong, and can be strengthened further by cold working.

- Martensitic steels contain moderate amounts of chromium, nickel, and carbon, They are magnetic and heat-treatable. Martensitic steels are often used for cutting tools such as knives and surgical equipment.

GRADES OF CARBON & ALLOY STEEL WE SUPPLY

There are four types of carbon steel based on the amount of carbon present in the alloy. Lower carbon steels are softer and more easily formed, and steels with a higher carbon content are harder and stronger, but less ductile, and they become more difficult to machine and weld. Below are the properties of the grades of carbon steel we supply:

Low Carbon Steel – Composition of 0.05%-0.25% carbon and up to 0.4% manganese. Also known as mild steel, it is a low-cost material that is easy to shape. While not as hard as higher-carbon steels, carburizing can increase its surface hardness.

Medium Carbon Steel – Composition of 0.29%-0.54% carbon, with 0.60%-1.65% manganese. Medium carbon steel is ductile and strong, with long-wearing properties.

High Carbon Steel – Composition of 0.55%-0.95% carbon, with 0.30%-0.90% manganese. It is very strong and holds shape memory well, making it ideal for springs and wire.

Very High Carbon Steel – Composition of 0.96%-2.1% carbon. Its high carbon content makes it an extremely strong material. Due to its brittleness, this grade requires special handling.