Analysis of WP304 Stainless Steel Elbows Hot Bending Forming

January 18, 2026Technical Characteristics, Manufacturing, and Industrial Applications of ASTM A234 WP5 Alloy Steel Pipe Fittings

Abstract: ASTM A234 WP5 alloy steel pipe fittings are critical components in high-temperature and high-pressure (HTHP) piping systems, widely used in petrochemical, power generation, and refining industries. This paper conducts an in-depth technical analysis of ASTM A234 WP5 alloy steel pipe fittings, focusing on their material composition, mechanical properties, heat treatment requirements, manufacturing processes, and performance under service conditions. The chemical composition of ASTM A234 WP5, dominated by chromium (4.0-6.0%) and molybdenum (0.44-0.65%), endows it with excellent high-temperature strength, corrosion resistance, and creep resistance. Through systematic analysis of manufacturing technologies such as forging, forming, and welding, combined with mechanical property tests and non-destructive testing methods, the quality control system of these fittings is elaborated. Furthermore, the industrial applications of ASTM A234 WP5 pipe fittings in petrochemical refineries, thermal power plants, and chemical processing units are discussed, along with their advantages compared to other material grades under moderate to elevated temperature conditions. Parameter tables detailing chemical compositions, mechanical properties, and heat treatment parameters are provided to support technical discussions. This research aims to provide a comprehensive technical reference for engineering applications, material selection, and quality assurance of ASTM A234 WP5 alloy steel pipe fittings in the piping industry.

Keywords: ASTM A234 WP5; Alloy Steel Pipe Fittings; High-Temperature Performance; Manufacturing Process; Quality Control; Industrial Application

1. Introduction

In the modern piping industry, especially in critical fields such as petrochemical engineering, power generation, and oil refining, pipe fittings are essential components that ensure the integrity, efficiency, and safety of piping systems. These components are responsible for connecting pipes, changing flow direction, adjusting pipe diameter, and accommodating thermal expansion, making them subject to complex loads including internal pressure, temperature cycling, and corrosive media erosion. With the trend of industrial equipment towards large-scale, high-efficiency, and high-reliability operation, the demand for pipe fittings with excellent high-temperature strength, corrosion resistance, and structural stability has become increasingly prominent.

ASTM A234 WP5 alloy steel pipe fittings, as a key grade under the ASTM A234 standard, are specifically designed for moderate to elevated temperature service conditions (ranging from 300℃ to 600℃) and medium to high pressure environments. The designation “ASTM A234” refers to the standard specification for wrought carbon steel and alloy steel pipe fittings, while “WP” denotes “wrought pipe” (indicating the fitting is manufactured from wrought material rather than cast), and “5” identifies the alloy grade—specifically a chromium-molybdenum (Cr-Mo) alloy with approximately 5% chromium and 0.5% molybdenum. This alloy composition distinguishes ASTM A234 WP5 from carbon steel fittings (e.g., ASTM A234 WPB) and other alloy grades (e.g., WP9, WP11, WP22), enabling it to perform reliably in environments where carbon steel may fail due to insufficient high-temperature strength or corrosion resistance.

This paper focuses on the technical characteristics and industrial applications of ASTM A234 WP5 alloy steel pipe fittings. The structure is organized as follows: Section 2 introduces the relevant standards and material designation system of ASTM A234 WP5; Section 3 details the chemical composition and mechanical properties, supported by parameter tables; Section 4 analyzes the heat treatment process and its influence on material performance; Section 5 discusses the manufacturing processes including forging, forming, and welding; Section 6 evaluates the service performance under high-temperature and high-pressure conditions; Section 7 presents typical industrial applications; Section 8 elaborates on quality control and testing methods; and Section 9 provides conclusions and prospects. This comprehensive analysis aims to provide valuable technical insights for undergraduate students, engineers, and researchers in the piping industry.

2. ASTM A234 Standard and Material Designation System

2.1 Overview of ASTM A234 Standard

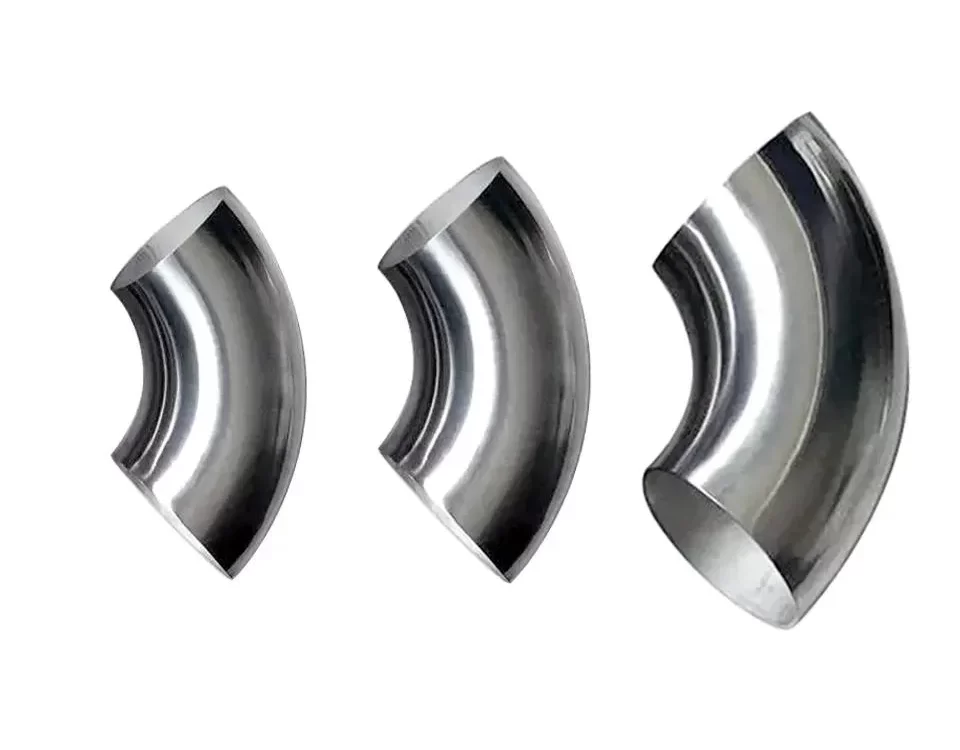

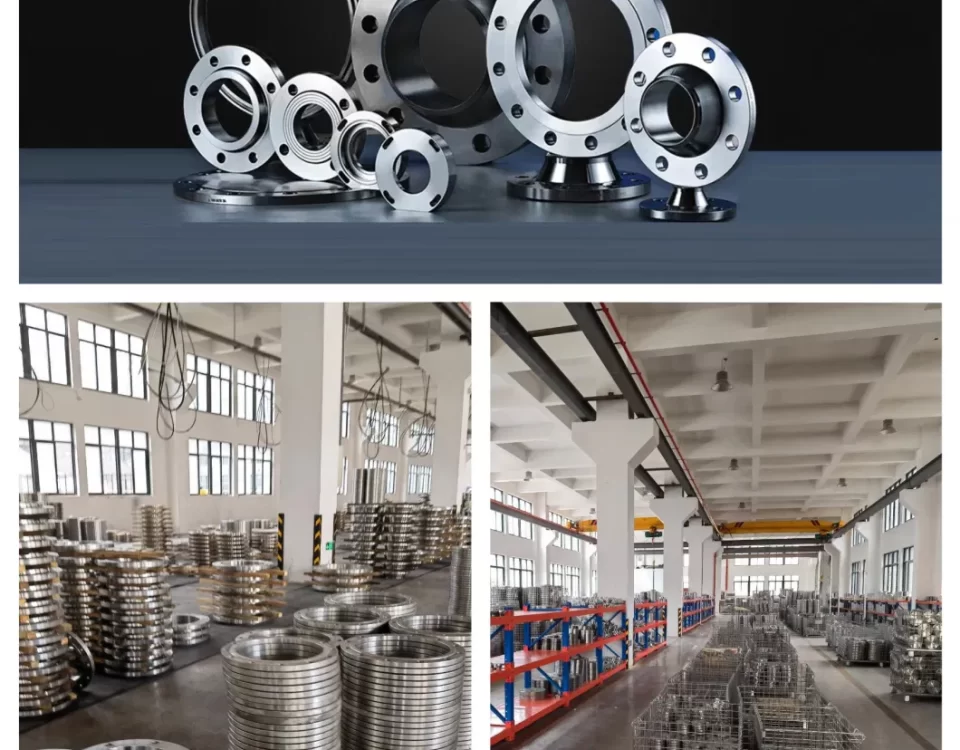

The ASTM A234 standard, issued by the American Society for Testing and Materials (ASTM), specifies the requirements for wrought carbon steel and alloy steel pipe fittings used in pressure piping and pressure vessel fabrication for moderate and elevated temperature service. This standard covers both seamless and welded fittings, including elbows, tees, reducers, caps, crosses, and lap joint stub ends, which comply with the latest revisions of ASME B16.9, ASME B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, and MSS-SP-97. Fittings that deviate from these ASME and MSS standards must be supplied in accordance with Supplementary Requirement S58 of ASTM A960/A960M.

A key feature of the ASTM A234 standard is its classification of material grades based on chemical composition and mechanical properties to meet diverse service requirements. Common grades include carbon steel grades (WPB, WPC) and alloy steel grades (WP5, WP9, WP11, WP12, WP22, WP91). Among these, alloy steel grades are formulated with additional alloying elements (chromium, molybdenum, nickel, etc.) to enhance high-temperature strength, corrosion resistance, and creep resistance, making them suitable for more severe service conditions compared to carbon steel grades.

2.2 Designation System of ASTM A234 WP5

The designation “ASTM A234 WP5” follows a standardized naming convention that conveys critical information about the material and its intended use:

-

ASTM: Abbreviation for the American Society for Testing and Materials, the issuing organization of the standard.

-

A234: The standard number, specifically governing wrought carbon steel and alloy steel pipe fittings.

-

WP: Stands for “Wrought Pipe,” indicating that the fitting is manufactured from wrought material (processed by forging, rolling, or extrusion) rather than cast material. Wrought materials typically exhibit better mechanical properties and structural uniformity compared to cast materials.

-

5: The alloy grade identifier, specifying a Cr-Mo alloy steel with a chromium content of 4.0-6.0% and a molybdenum content of 0.44-0.65%. This grade is specifically designed for moderate high-temperature service.

It should be noted that when ASTM A234 WP5 fittings are of welded construction, the grade designation must be supplemented with the letter “W” (e.g., WP5W) to indicate the welded structure. Additionally, ASTM A234 WP5 is available in two classes (CL1 and CL3) with different mechanical property requirements, as detailed in Section 3.2.

2.3 Equivalent Materials and Standard Compliance

ASTM A234 WP5 has equivalent materials in different standard systems to facilitate international industrial applications. For example, its equivalent material in the Chinese standard (GB) is Cr5Mo. These equivalent materials have similar chemical compositions and mechanical properties, ensuring interchangeability in specific applications. However, it is crucial to verify compliance with local standards and engineering requirements when selecting equivalent materials.

In addition to complying with ASTM A234, WP5 pipe fittings must also meet the requirements of relevant pressure vessel and piping standards, such as ASME Boiler and Pressure Vessel Code (BPVC) Section VIII (Pressure Vessels) and Section B31 (Pressure Piping). These standards specify additional requirements for material testing, manufacturing processes, and quality assurance to ensure the safety and reliability of fittings in critical applications.

3. Chemical Composition and Mechanical Properties of ASTM A234 WP5

The excellent performance of ASTM A234 WP5 alloy steel pipe fittings is fundamentally determined by their chemical composition. The precise control of alloying elements (chromium, molybdenum, carbon, etc.) ensures the material’s high-temperature strength, corrosion resistance, and weldability. This section details the chemical composition and mechanical properties of ASTM A234 WP5, supported by standardized parameter tables.

3.1 Chemical Composition

ASTM A234 WP5 is a low-alloy steel primarily alloyed with chromium and molybdenum. The chromium content enhances corrosion resistance and high-temperature oxidation resistance, while molybdenum improves overall strength and creep resistance by refining the grain structure and increasing the material’s resistance to plastic deformation at elevated temperatures. The chemical composition of ASTM A234 WP5 (CL1 and CL3) is specified in Table 1, in accordance with ASTM A234 and relevant industrial standards.

|

Element

|

ASTM A234 WP5 CL1 & CL3

|

Function

|

|---|---|---|

|

Carbon (C)

|

≤ 0.15

|

Enhances strength and hardness; controlled to ≤ 0.15% to ensure good weldability and avoid excessive carbide precipitation at elevated temperatures.

|

|

Silicon (Si)

|

≤ 0.50

|

Acts as a deoxidizer during steelmaking; improves oxidation resistance and strength.

|

|

Manganese (Mn)

|

0.30 – 0.60

|

Improves strength and toughness; enhances the hardenability of the material.

|

|

Phosphorus (P)

|

≤ 0.040

|

Harmful impurity; controlled to a low level to avoid reducing toughness and increasing brittleness.

|

|

Sulfur (S)

|

≤ 0.030

|

Harmful impurity; causes hot brittleness during processing; strictly controlled to ensure good ductility and toughness.

|

|

Chromium (Cr)

|

4.0 – 6.0

|

Key alloying element; improves high-temperature oxidation resistance and corrosion resistance; enhances strength at elevated temperatures.

|

|

Molybdenum (Mo)

|

0.44 – 0.65

|

Key alloying element; improves creep resistance and high-temperature strength; refines grain structure and enhances toughness.

|

|

Nickel (Ni)

|

≤ 0.40 (typical)

|

Trace element; improves toughness and corrosion resistance in certain environments.

|

The chemical composition of ASTM A234 WP5 is strictly controlled to ensure consistent performance. For example, the carbon content is limited to a maximum of 0.15% to prevent the formation of excessive chromium carbides (Cr₃C₆) at elevated temperatures, which could reduce the material’s toughness and corrosion resistance. The combination of chromium and molybdenum forms a synergistic effect, significantly improving the material’s resistance to high-temperature oxidation and creep deformation, making it suitable for long-term service at temperatures up to 600℃.

3.2 Mechanical Properties

The mechanical properties of ASTM A234 WP5, including tensile strength, yield strength, elongation, and hardness, are critical indicators of its performance in piping systems. These properties are influenced by the chemical composition and heat treatment process. ASTM A234 WP5 is available in two classes (CL1 and CL3) with different mechanical property requirements, as shown in Table 2. The elongation requirements vary with the thickness of the fitting, as detailed in Table 3.

|

Property

|

ASTM A234 WP5 CL1

|

ASTM A234 WP5 CL3

|

Test Standard

|

|---|---|---|---|

|

Tensile Strength (TS), min

|

415 MPa (60 ksi)

|

520 MPa (75 ksi)

|

ASTM E8/E8M

|

|

Yield Strength (YS, 0.2% offset), min

|

205 MPa (30 ksi)

|

310 MPa (45 ksi)

|

ASTM E8/E8M

|

|

Hardness (HB), max

|

217 HB

|

217 HB

|

ASTM E10

|

|

Sample Type/Thickness

|

Longitudinal

|

Transverse

|

Notes

|

|---|---|---|---|

|

Standard round specimen (4D gauge length)

|

22

|

14

|

Applicable to all thicknesses

|

|

Rectangular specimen (thickness ≥ 7.94 mm, 2 in. gauge length)

|

30

|

20

|

Full-section or small-size specimen

|

|

Thickness = 7.14 mm (9/32 in.)

|

28.5

|

19.0

|

Calculated by linear interpolation

|

|

Thickness = 6.35 mm (1/4 in.)

|

27.0

|

18.0

|

Calculated by linear interpolation

|

|

Thickness = 1.59 mm (1/16 in.)

|

18.0

|

–

|

Transverse elongation not required

|

The mechanical properties of ASTM A234 WP5 are closely related to the heat treatment process. For example, CL3 fittings have higher tensile and yield strengths compared to CL1 fittings, which is achieved through a more rigorous heat treatment process (e.g., normalizing and tempering). The elongation requirements decrease with decreasing specimen thickness, which is accounted for by the formula E = 48t + 15.00 (longitudinal) and E = 32t + 10.00 (transverse), where E is the elongation (%) and t is the specimen thickness (in.). This ensures that the material maintains sufficient ductility even for thin-walled fittings, preventing brittle fracture during installation and service.

Comparative analysis with other ASTM A234 grades (Table 4) shows that ASTM A234 WP5 has higher tensile strength and yield strength than carbon steel grades (WPB, WPC) and similar strength to low-alloy grades such as WP11, but lower strength than high-alloy grades such as WP22 and WP91. However, WP5 offers a balance of cost and performance, making it a preferred choice for moderate high-temperature and pressure applications.

|

Grade

|

Tensile Strength (MPa), min

|

Yield Strength (MPa), min

|

Elongation (%), min

|

Max Service Temperature (℃)

|

|---|---|---|---|---|

|

WPB (Carbon Steel)

|

415

|

240

|

22

|

425

|

|

WPC (Carbon Steel)

|

485

|

275

|

22

|

425

|

|

WP5 CL1 (Alloy Steel)

|

415

|

205

|

22

|

600

|

|

WP5 CL3 (Alloy Steel)

|

520

|

310

|

22

|

600

|

|

WP11 (Alloy Steel)

|

415

|

205

|

22

|

595

|

|

WP22 (Alloy Steel)

|

415

|

205

|

22

|

650

|

|

WP91 (Alloy Steel)

|

585

|

415

|

20

|

650

|

4. Heat Treatment of ASTM A234 WP5

Heat treatment is a critical process in the manufacturing of ASTM A234 WP5 alloy steel pipe fittings, as it directly affects the material’s microstructure and mechanical properties. The goal of heat treatment is to refine the grain structure, reduce residual stresses, improve toughness, and ensure consistent performance. This section details the heat treatment requirements, processes, and their effects on the performance of ASTM A234 WP5.

4.1 Heat Treatment Requirements

According to the ASTM A234 standard, ASTM A234 WP5 pipe fittings must be delivered after heat treatment, which typically includes full annealing or normalizing and tempering. The specific heat treatment requirements are as follows:

-

Full Annealing: The fitting is heated to a temperature of 815-870℃ (1500-1600℉), held at this temperature for a sufficient time to ensure uniform heating, and then cooled slowly in the furnace to below the critical range (approximately 595℃, 1100℉). This process reduces hardness, improves ductility and toughness, and eliminates residual stresses.

-

Normalizing and Tempering: Normalizing involves heating the fitting to 890-950℃ (1635-1740℉), holding for a sufficient time, and then cooling in still air. Tempering is performed by reheating the normalized fitting to a minimum temperature of 675℃ (1250℉), holding for a sufficient time, and then cooling in air or water. This process refines the grain structure, improves strength and toughness, and ensures consistent mechanical properties. CL3 fittings typically require normalizing and tempering to achieve higher strength requirements.

A key requirement is that after hot forming (at temperatures exceeding 980℃, 1800℉), fittings must be cooled to below the critical range at a rate no faster than the cooling rate in still air to prevent the formation of harmful microstructures (e.g., martensite) that could reduce toughness and increase brittleness. The heat treatment temperature is measured as the metal temperature (part temperature), not the furnace temperature, to ensure accurate control.

4.2 Heat Treatment Process Parameters

The heat treatment process parameters for ASTM A234 WP5 are critical to achieving the desired mechanical properties. Table 5 summarizes the typical heat treatment parameters for CL1 and CL3 fittings.

|

Heat Treatment Type

|

Heating Temperature (℃)

|

Holding Time (min/in. of thickness)

|

Cooling Method

|

Applicable Grade

|

|---|---|---|---|---|

|

Full Annealing

|

815-870

|

30-60

|

Furnace cooling (≤ 55℃/h below 595℃)

|

CL1, CL3

|

|

Normalizing

|

890-950

|

15-30

|

Air cooling

|

CL3 (prior to tempering)

|

|

Tempering

|

≥ 675

|

30-60

|

Air cooling or water cooling

|

CL3 (after normalizing)

|

The holding time is determined based on the thickness of the fitting to ensure uniform heating and microstructure transformation. For example, a fitting with a thickness of 20 mm (0.79 in.) would require a holding time of 60-120 minutes for full annealing. The cooling rate during annealing is strictly controlled to avoid the formation of hard and brittle microstructures. For normalizing, air cooling ensures the formation of a fine-grained pearlitic microstructure, which provides a good balance of strength and toughness. Tempering after normalizing further reduces residual stresses and improves ductility.

4.3 Effect of Heat Treatment on Microstructure and Performance

The microstructure of ASTM A234 WP5 after heat treatment is primarily composed of ferrite and pearlite, with fine grain size. This microstructure ensures good mechanical properties, including high-temperature strength, ductility, and toughness. The effect of heat treatment on the performance of ASTM A234 WP5 is as follows:

-

Strength and Hardness: Normalizing and tempering increase the tensile and yield strengths of the material compared to full annealing. For example, CL3 fittings treated with normalizing and tempering have a yield strength of 310 MPa, which is 51% higher than the 205 MPa yield strength of CL1 fittings treated with full annealing.

-

Ductility and Toughness: Full annealing results in the highest ductility and toughness, making it suitable for fittings that require extensive forming or welding. Normalizing and tempering provide a balance of strength and toughness, suitable for high-pressure applications.

-

Residual Stresses: Heat treatment effectively reduces residual stresses introduced during hot forming and welding, minimizing the risk of stress corrosion cracking during service.

-

High-Temperature Performance: The fine-grained microstructure resulting from proper heat treatment enhances the material’s creep resistance and high-temperature oxidation resistance, ensuring long-term service reliability at temperatures up to 600℃.

Improper heat treatment (e.g., insufficient heating temperature, inadequate holding time, or excessive cooling rate) can lead to undesirable microstructures, such as martensite or bainite, which reduce the material’s toughness and increase brittleness. Therefore, strict process control during heat treatment is essential to ensure the quality and performance of ASTM A234 WP5 pipe fittings.

5. Manufacturing Processes of ASTM A234 WP5 Pipe Fittings

The manufacturing of ASTM A234 WP5 alloy steel pipe fittings involves a series of processes, including raw material selection, forging, hot forming, welding, heat treatment, and machining. Each process step must be strictly controlled to ensure the dimensional accuracy, structural integrity, and performance of the final product. This section details the key manufacturing processes and their technical requirements.

5.1 Raw Material Selection

The raw material for ASTM A234 WP5 pipe fittings must be fully killed steel, which is steel that has been completely deoxidized to minimize the oxygen content and avoid the formation of porosity and other defects. The raw material can be in the form of forgings, bars, plates, sheets, or seamless/fusion-welded pipes with filler metal added, and must comply with the chemical composition requirements specified in Table 1. Prior to processing, the raw material must be inspected for chemical composition (through material test reports, MTR) and surface defects (e.g., cracks, inclusions) to ensure quality.

Positive Material Identification (PMI) is typically performed on the raw material to verify the chemical composition, ensuring that the material is consistent with the ASTM A234 WP5 specification. This is particularly important to prevent material mixing, which could lead to performance failures in critical applications.

5.2 Forging and Hot Forming

Forging is a key process for shaping ASTM A234 WP5 pipe fittings, as it improves the material’s microstructure, enhances mechanical properties, and eliminates internal defects. The forging process involves heating the raw material to a temperature of 1050-1200℃ (1920-2190℉), where the steel has good plasticity, and then shaping it using hammering, pressing, piercing, upsetting, or rolling techniques. Hot forming is typically used for fittings such as elbows, tees, and reducers, where complex shapes are required.

Key technical requirements for forging and hot forming include:

-

Forming Temperature: The forming temperature must be controlled within the range of 1050-1200℃ to ensure good plasticity and avoid the formation of harmful microstructures. Forming at temperatures exceeding 980℃ (1800℉) requires subsequent heat treatment (annealing, normalizing, or normalizing and tempering) as specified in Section 4.

-

Cooling Rate: After hot forming, the fitting must be cooled to below the critical range (≤ 595℃) at a rate no faster than the cooling rate in still air to prevent the formation of martensite and other brittle microstructures.

-

Dimensional Accuracy: The forging process must be controlled to ensure the dimensional accuracy of the fitting, including outer diameter, inner diameter, wall thickness, and angle (for elbows). Dimensional tolerances must comply with ASME B16.9 and other relevant standards.

-

Defect Prevention: Forging must be performed to avoid the formation of injurious defects, such as cracks, laps, seams, and internal porosity. These defects can significantly reduce the structural integrity and performance of the fitting.

5.3 Welding Process

Welding is used to manufacture welded ASTM A234 WP5 fittings (designated as WP5W) or to repair defects in forged fittings. The welding process must be carefully controlled to ensure good weld quality, as welds are often the weak point in piping systems. Common welding processes for ASTM A234 WP5 include shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW), and gas metal arc welding (GMAW).

Key technical requirements for welding include:

-

Welding Consumables: The welding consumables (electrodes, filler metal) must be compatible with ASTM A234 WP5, with a chemical composition similar to the base material to ensure consistent performance. For example, E410NiMo electrodes are commonly used for SMAW of WP5 fittings.

-

Preheating and Post-Weld Heat Treatment (PWHT): Preheating to a temperature of 150-250℃ is typically required to reduce the cooling rate of the weld, prevent the formation of martensite, and avoid cold cracking. Post-weld heat treatment (tempering at ≥ 675℃) is necessary to reduce residual stresses, improve weld toughness, and ensure the weld metal has mechanical properties consistent with the base material.

-

Weld Quality Control: Welds must be inspected for defects using non-destructive testing (NDT) methods, such as radiographic testing (RT), ultrasonic testing (UT), magnetic particle testing (MT), or liquid penetrant testing (PT). Weld defects such as cracks, porosity, and incomplete fusion must be repaired and re-inspected before the fitting is accepted.

5.4 Machining and Finishing

After forging, forming, and heat treatment, ASTM A234 WP5 fittings undergo machining to achieve the final dimensional accuracy and surface finish. Machining processes include turning, milling, and drilling, which are used to machine the end faces, grooves, and threads (if required) of the fittings.

Key technical requirements for machining include:

-

Surface Finish: The surface finish of the fitting must comply with ASME B16.9, typically requiring a surface roughness (Ra) of ≤ 6.3 μm to ensure good weldability and prevent stress concentration.

-

Dimensional Tolerances: Machining must be controlled to ensure tight dimensional tolerances, including wall thickness variation (≤ ±10% of the nominal wall thickness), end face perpendicularity, and groove dimensions.

-

Deburring and Cleaning: After machining, the fitting must be deburred to remove sharp edges and cleaned to remove oil, grease, and debris, which could affect welding quality and service performance.

6. Service Performance of ASTM A234 WP5 Under High-Temperature and High-Pressure Conditions

ASTM A234 WP5 alloy steel pipe fittings are primarily designed for service in moderate to elevated temperature (300-600℃) and medium to high pressure (up to 10 MPa) environments. Their service performance, including high-temperature strength, creep resistance, corrosion resistance, and fatigue resistance, is critical to the reliability and safety of piping systems. This section evaluates the service performance of ASTM A234 WP5 based on experimental data and industrial practice.

6.1 High-Temperature Strength and Creep Resistance

High-temperature strength and creep resistance are key performance indicators for materials used in elevated temperature applications. Creep is the time-dependent plastic deformation of a material under constant load and elevated temperature, which can lead to premature failure of fittings over long-term service. The chromium and molybdenum content in ASTM A234 WP5 enhances its creep resistance by forming stable carbides and refining the grain structure.

Table 6 presents the typical creep properties of ASTM A234 WP5 at different temperatures. The data shows that the creep rupture strength decreases with increasing temperature, as expected. At 500℃, the creep rupture strength for 10,000 hours is approximately 120 MPa, which is sufficient for most moderate high-temperature applications (e.g., petrochemical refineries, thermal power plants).

|

Temperature (℃)

|

Creep Rupture Strength (MPa) for 10,000 h

|

Creep Rupture Strength (MPa) for 100,000 h

|

|---|---|---|

|

450

|

150

|

110

|

|

500

|

120

|

85

|

|

550

|

85

|

55

|

|

600

|

50

|

30

|

Experimental studies have shown that ASTM A234 WP5 maintains good high-temperature strength up to 600℃. At temperatures above 600℃, the creep rate increases significantly, and the material’s service life is greatly reduced. Therefore, the maximum recommended service temperature for ASTM A234 WP5 is 600℃, as shown in Table 4.

6.2 Corrosion Resistance

ASTM A234 WP5 exhibits good corrosion resistance in a variety of environments, including high-temperature steam, hydrocarbon media, and weak corrosive media. The chromium content forms a protective oxide layer (Cr₂O₃) on the surface of the material, which prevents further oxidation and corrosion. Molybdenum enhances the material’s resistance to pitting corrosion and crevice corrosion in chloride-containing environments.

The corrosion resistance of ASTM A234 WP5 is evaluated by its corrosion rate in different environments (Table 7). The data shows that the corrosion rate is low in high-temperature steam and hydrocarbon media, making it suitable for use in refineries and petrochemical plants. In chloride-containing environments, the corrosion rate increases, but it is still acceptable for moderate chloride concentrations (≤ 100 ppm).

|

Environment

|

Temperature (℃)

|

Corrosion Rate (mm/year)

|

|---|---|---|

|

High-temperature steam (10 MPa)

|

500

|

0.01-0.03

|

|

Hydrocarbon gas (methane + ethane)

|

550

|

0.02-0.04

|

|

Weak acid solution (pH = 4-6)

|

100

|

0.05-0.10

|

|

Chloride-containing water (100 ppm Cl⁻)

|

200

|

0.08-0.12

|

It should be noted that ASTM A234 WP5 is not suitable for highly corrosive environments, such as strong acids, strong bases, or high chloride concentrations (≥ 1000 ppm), where more corrosion-resistant materials (e.g., stainless steel, nickel-based alloys) should be used.

6.3 Fatigue Resistance

Fatigue failure is a common failure mode for pipe fittings subjected to cyclic loads, such as temperature cycling and pressure fluctuations. The fatigue resistance of ASTM A234 WP5 is influenced by its mechanical properties, microstructure, and surface finish. The fine-grained microstructure resulting from proper heat treatment enhances the material’s fatigue resistance.

The fatigue strength of ASTM A234 WP5 (CL3) at room temperature is approximately 200 MPa for 10⁷ cycles. At elevated temperatures (500℃), the fatigue strength decreases to approximately 120 MPa for 10⁷ cycles. Proper design (e.g., avoiding sharp corners, minimizing stress concentration) and quality control (e.g., ensuring good surface finish, reducing residual stresses) can further improve the fatigue resistance of the fittings.

7. Industrial Applications of ASTM A234 WP5 Pipe Fittings

Due to its excellent high-temperature strength, creep resistance, and corrosion resistance, ASTM A234 WP5 alloy steel pipe fittings are widely used in critical industrial applications, including petrochemical refineries, thermal power plants, chemical processing units, and boiler systems. This section details the typical applications and advantages of ASTM A234 WP5 in these industries.

7.1 Petrochemical Refineries

Petrochemical refineries involve processes such as distillation, cracking, and reforming, which operate at moderate to elevated temperatures (300-600℃) and high pressures. ASTM A234 WP5 pipe fittings are used in various refinery systems, including:

-

Distillation Columns: Used in the piping systems connecting distillation columns, where the temperature ranges from 350-550℃ and the pressure ranges from 1-5 MPa. WP5 fittings ensure reliable connection and flow control of hydrocarbon fractions.

-

Cracking Units: Used in fluid catalytic cracking (FCC) and hydrocracking units, where the temperature can reach 500-600℃ and the pressure can exceed 10 MPa. WP5 fittings’ high-temperature strength and creep resistance make them suitable for these severe service conditions.

-

Heat Exchangers: Used in the inlet and outlet piping of heat exchangers, where the temperature changes between 200-550℃. WP5 fittings’ good thermal conductivity and corrosion resistance ensure efficient heat transfer and long service life.

The advantage of using ASTM A234 WP5 in refineries is its balance of cost and performance. Compared to carbon steel fittings (e.g., WPB), WP5 offers better high-temperature strength and corrosion resistance, reducing the risk of failure. Compared to high-alloy fittings (e.g., WP91), WP5 is more cost-effective, making it a preferred choice for moderate high-temperature applications.

7.2 Thermal Power Plants

Thermal power plants generate electricity by heating water to produce high-temperature steam, which drives turbines. The steam piping systems in thermal power plants operate at temperatures of 450-550℃ and pressures of 10-15 MPa. ASTM A234 WP5 pipe fittings are used in the following systems:

-

Boiler Piping: Used in the piping connecting the boiler to the turbine, where the steam temperature is 450-550℃ and the pressure is 10-15 MPa. WP5 fittings’ high-temperature strength and creep resistance ensure the integrity of the steam piping system.

-

Superheater and Reheater Piping: Used in the superheater and reheater systems, where the steam is heated to temperatures up to 550℃. WP5 fittings’ good oxidation resistance and high-temperature strength make them suitable for these applications.

-

Feedwater Piping: Used in the feedwater system, where the water temperature is 200-300℃ and the pressure is 15-20 MPa. WP5 fittings’ high-pressure strength and corrosion resistance ensure reliable water supply to the boiler.

In thermal power plants, the reliability of pipe fittings is critical to the safe and efficient operation of the plant. ASTM A234 WP5 fittings have a proven track record of reliability in steam piping systems, reducing the risk of unplanned downtime.

7.3 Chemical Processing Units

Chemical processing units involve the production of various chemicals, such as fertilizers, plastics, and pharmaceuticals, which often require high-temperature and high-pressure reactions. ASTM A234 WP5 pipe fittings are used in the following applications:

-

Reactor Piping: Used in the piping connecting reactors, where the temperature ranges from 300-500℃ and the pressure ranges from 5-10 MPa. WP5 fittings’ corrosion resistance and high-temperature strength ensure the safe transport of reactive chemicals.

-

Solvent Recovery Systems: Used in solvent recovery systems, where the temperature is 250-400℃ and the pressure is 1-3 MPa. WP5 fittings’ good chemical resistance ensures compatibility with various solvents.

The advantage of using ASTM A234 WP5 in chemical processing units is its versatility and compatibility with a wide range of chemicals. Its corrosion resistance makes it suitable for use with hydrocarbons, weak acids, and weak bases, while its high-temperature strength makes it suitable for high-temperature reaction processes.

8. Quality Control and Testing Methods

Quality control is essential to ensure the performance and reliability of ASTM A234 WP5 alloy steel pipe fittings. A comprehensive quality control system includes raw material inspection, in-process inspection, and final product testing. This section details the key quality control measures and testing methods for ASTM A234 WP5 fittings.

8.1 Raw Material Inspection

Raw material inspection is the first step in quality control, ensuring that the raw material meets the chemical composition and mechanical property requirements of ASTM A234 WP5. Key inspection items include:

-

Chemical Composition Analysis: Performed using optical emission spectroscopy (OES) or X-ray fluorescence (XRF) to verify the chemical composition of the raw material. The results must comply with the requirements specified in Table 1 (Chemical Composition of ASTM A234 WP5). For critical applications, additional wet chemical analysis may be required to confirm the content of key alloying elements such as chromium and molybdenum, ensuring no deviations that could affect the material’s high-temperature performance.

-

Mechanical Property Verification: Review of the Material Test Report (MTR) provided by the raw material supplier to confirm that the mechanical properties (tensile strength, yield strength, elongation, etc.) of the raw material meet the preliminary requirements of ASTM A234 WP5. If there are doubts about the MTR data, supplementary mechanical property tests (e.g., tensile test) may be conducted on the raw material samples.

-

Surface Defect Inspection: Visual inspection (VT) of the raw material surface to check for defects such as cracks, inclusions, scratches, and pits. For raw materials with a specified surface finish requirement, a surface roughness tester may be used to verify the surface roughness. Any surface defects that exceed the allowable range must be repaired or the raw material rejected.

-

Macrostructure and Microstructure Inspection: Forging blanks or thick-walled raw materials may require macrostructure inspection (e.g., acid etching test) to check for internal defects such as porosity, segregation, and shrinkage. Microstructure inspection (using optical microscopy) can be performed to confirm that the raw material has a uniform ferrite-pearlite structure without harmful phases such as martensite or bainite, which could affect subsequent processing and performance.

In addition to the above items, the raw material’s dimensions (e.g., diameter, thickness, length) must be inspected to ensure they meet the requirements of subsequent processing. Any raw material that fails to pass the inspection must be isolated and not used for manufacturing ASTM A234 WP5 pipe fittings.

8.2 In-Process Quality Control

In-process quality control covers all key manufacturing stages from forging/hot forming to welding and heat treatment, aiming to detect and correct defects in a timely manner and ensure the stability of the manufacturing process. Key in-process inspection items include:

-

Forging and Hot Forming Inspection: Real-time monitoring of the forming temperature using infrared thermometers or thermocouples to ensure it remains within the range of 1050-1200℃. After forming, dimensional inspection of the semi-finished fittings (including outer diameter, inner diameter, wall thickness, angle, and length) is conducted using calipers, micrometers, and angle gauges, with tolerances complying with ASME B16.9. Visual inspection is also performed to check for surface defects such as cracks, laps, and seams caused by improper forming.

-

Welding Process Inspection: Monitoring of welding parameters (welding current, voltage, welding speed, and shielding gas flow rate) to ensure they are consistent with the qualified Welding Procedure Specification (WPS). Preheating temperature and interpass temperature are measured using temperature-indicating crayons or thermocouples to prevent cold cracking. After welding, visual inspection of the weld seam is carried out to check for appearance defects such as undercut, overlap, incomplete penetration, and excessive reinforcement. The weld seam width and height must meet the specified requirements.

-

Heat Treatment Process Inspection: Recording and monitoring of the heat treatment furnace temperature curve to ensure the heating temperature, holding time, and cooling rate comply with the requirements specified in Table 5 (Typical Heat Treatment Parameters for ASTM A234 WP5). The metal temperature of the fittings during heat treatment is verified using thermocouples attached to the fitting surface. After heat treatment, hardness testing (using Brinell hardness tester) is performed to confirm that the hardness does not exceed the maximum limit of 217 HB, ensuring the material has appropriate toughness.

In-process inspection also includes process documentation control, such as recording the operator, equipment, time, and parameters for each process step. This documentation provides a traceable record for subsequent quality tracing and problem investigation.

8.3 Final Product Testing

Final product testing is the last quality control barrier before the fittings leave the factory, ensuring that the finished ASTM A234 WP5 pipe fittings meet all technical requirements and can be safely used in practical applications. Key final testing items include:

-

Non-Destructive Testing (NDT): NDT methods are widely used in final product testing due to their ability to detect internal and surface defects without damaging the product. Common NDT methods for ASTM A234 WP5 fittings include: – Radiographic Testing (RT): Used to inspect internal defects of welds and forged parts, such as cracks, porosity, incomplete fusion, and slag inclusions. The inspection scope and acceptance criteria comply with ASME Section V, Article 2. – Ultrasonic Testing (UT): Suitable for detecting internal defects in thick-walled fittings and welds, with high sensitivity to planar defects such as cracks. It is often used as a supplementary or alternative method to RT. – Magnetic Particle Testing (MT): Used to detect surface and near-surface defects (e.g., cracks, seams) in ferromagnetic materials like ASTM A234 WP5. It is typically applied to the fitting surface and weld seams after machining. – Liquid Penetrant Testing (PT): Used to detect surface open defects (e.g., cracks, pinholes) in non-magnetic or magnetic materials. It is suitable for fittings with complex shapes where MT is not applicable. The specific NDT methods and inspection ranges are determined based on the fitting’s size, thickness, and application requirements. Defects that do not meet the acceptance criteria must be repaired, and re-testing is required after repair until qualified.

-

Final Dimensional Inspection: Comprehensive dimensional inspection of the finished fittings using precision measuring tools (e.g., coordinate measuring machine, laser range finder) to confirm that all dimensions (including end face perpendicularity, groove dimensions, thread dimensions if applicable) meet the requirements of ASME B16.9 and the product drawing. Dimensional deviations must be within the allowable tolerance range to ensure interchangeability and assembly performance with pipes.

-

Mechanical Property Testing of Finished Products: Sampling testing of finished fittings is conducted in accordance with ASTM A234 requirements. Common tests include tensile test, impact test, and creep test. The tensile test verifies the tensile strength and yield strength of the finished product, ensuring they meet the requirements of CL1 or CL3 (Table 2). The impact test (especially at low temperatures or service temperatures) evaluates the material’s toughness, preventing brittle fracture. For fittings used in long-term high-temperature service, creep rupture test may be performed to confirm the creep resistance meets the design requirements.

-

Corrosion Resistance Testing: For fittings used in corrosive environments, supplementary corrosion resistance tests may be conducted, such as salt spray test, high-temperature steam oxidation test, or immersion test in simulated service media. These tests verify that the fitting’s corrosion rate is within the allowable range, ensuring long-term service reliability in corrosive environments.

-

Cleanliness and Surface Finish Inspection: Inspection of the finished fitting’s surface finish using a surface roughness tester to confirm Ra ≤ 6.3 μm. Check the cleanliness of the fitting interior and exterior to ensure no oil, grease, debris, or rust remains. For fittings used in high-purity media (e.g., petrochemical refined products), additional cleaning and inspection procedures may be required.

After all final product tests are completed, a Final Inspection Report is issued, summarizing the test results and confirming that the finished fittings comply with ASTM A234 WP5 and relevant application standards. Only fittings that pass the final inspection can be labeled, packaged, and delivered.

8.4 Quality Documentation and Traceability

A complete quality documentation system is an important part of quality control for ASTM A234 WP5 pipe fittings, ensuring traceability of the entire production process. Key quality documents include:

-

Material Test Report (MTR): Provided for each batch of raw materials, including chemical composition, mechanical properties, heat treatment history, and inspection results.

-

Welding Procedure Specification (WPS) and Procedure Qualification Record (PQR): Documenting the welding parameters and qualification results, ensuring the welding process is qualified and repeatable.

-

Heat Treatment Record: Recording the furnace temperature curve, heating time, holding time, cooling rate, and operator information for each batch of fittings.

-

Non-Destructive Testing Report: Detailing the NDT methods used, inspection scope, defect location and size (if any), and acceptance results.

-

Final Inspection Report: Summarizing the final dimensional inspection, mechanical property testing, corrosion resistance testing, and cleanliness inspection results.

Each finished fitting should be marked with a unique identification code (e.g., batch number, heat number), which can be traced back to the raw material, manufacturing process, and inspection results. This traceability system allows for quick investigation and handling in case of quality problems, ensuring the safety and reliability of the piping system.

9. Conclusions and Prospects

ASTM A234 WP5 alloy steel pipe fittings, as a key component in moderate to elevated temperature and medium to high pressure piping systems, exhibit excellent comprehensive performance due to their reasonable chromium-molybdenum alloy composition, strict manufacturing processes, and standardized heat treatment. This paper systematically analyzes the technical characteristics, manufacturing processes, service performance, industrial applications, and quality control methods of ASTM A234 WP5, leading to the following conclusions:

-

The chemical composition of ASTM A234 WP5 (4.0-6.0% Cr, 0.44-0.65% Mo) endows it with excellent high-temperature strength, creep resistance, and corrosion resistance, making it suitable for long-term service at temperatures up to 600℃. The two classes (CL1 and CL3) with different mechanical properties meet the diverse requirements of different pressure and load conditions.

-

Proper heat treatment (full annealing or normalizing and tempering) is crucial to ensuring the performance of ASTM A234 WP5. Strict control of heat treatment parameters (heating temperature, holding time, cooling rate) can refine the grain structure, reduce residual stresses, and achieve the desired balance of strength and toughness.

-

The manufacturing processes of ASTM A234 WP5 (raw material selection, forging/hot forming, welding, machining) require strict technical control. Especially in forging temperature control, welding process parameter monitoring, and post-weld heat treatment, any deviation may lead to defects and affect product performance.

-

ASTM A234 WP5 pipe fittings have broad industrial applications in petrochemical refineries, thermal power plants, and chemical processing units, providing reliable support for the safe and efficient operation of critical industrial systems. Their balance of cost and performance makes them a preferred choice for moderate high-temperature and pressure applications compared to carbon steel and high-alloy steel fittings.

-

A comprehensive quality control system covering raw material inspection, in-process inspection, and final product testing, combined with complete quality documentation and traceability, is an effective guarantee for the quality and reliability of ASTM A234 WP5 pipe fittings. The application of multiple non-destructive testing methods and mechanical property tests ensures that the finished products meet the requirements of relevant standards.

Looking forward, with the continuous development of industrial technology towards higher efficiency, higher reliability, and lower carbon emissions, the requirements for pipe fittings in high-temperature and high-pressure environments will become more stringent. For ASTM A234 WP5 alloy steel pipe fittings, future research and development directions may include:

-

Optimization of Alloy Composition: On the basis of the existing chromium-molybdenum composition, adding trace alloying elements (e.g., vanadium, niobium) to further improve high-temperature creep resistance and corrosion resistance, expanding the application range to higher temperature and more severe corrosive environments.

-

Advancement of Manufacturing Processes: Adopting advanced manufacturing technologies such as precision forging, additive manufacturing (3D printing), and automated welding to improve dimensional accuracy, reduce defects, and enhance production efficiency. The application of intelligent monitoring systems in the manufacturing process can realize real-time tracking and control of process parameters, improving the stability of product quality.

-

Improvement of Testing and Evaluation Methods: Developing more efficient and accurate non-destructive testing technologies (e.g., phased array ultrasonic testing, eddy current testing) to detect micro-defects in fittings more effectively. Establishing a more comprehensive performance evaluation system that combines long-term service data and accelerated aging tests to predict the service life of ASTM A234 WP5 fittings more accurately.

-

Promotion of Standardization and Internationalization: Strengthening the alignment and integration of ASTM A234 standards with international and regional standards (e.g., EN, JIS) to facilitate the global circulation and application of ASTM A234 WP5 pipe fittings. Formulating more detailed application guidelines for different industries to provide more targeted technical support for engineering practice.

In conclusion, ASTM A234 WP5 alloy steel pipe fittings will continue to play an important role in the critical piping systems of the energy and chemical industries. Through continuous technological innovation and quality improvement, their performance and application scope will be further expanded, contributing to the safe, efficient, and sustainable development of the global industrial sector.