AISI 317L Stainless Steel Pipe | UNS S31703 DIN 1.4438

December 16, 2025

Corten Steel ASTM A242 Pipe

December 27, 2025

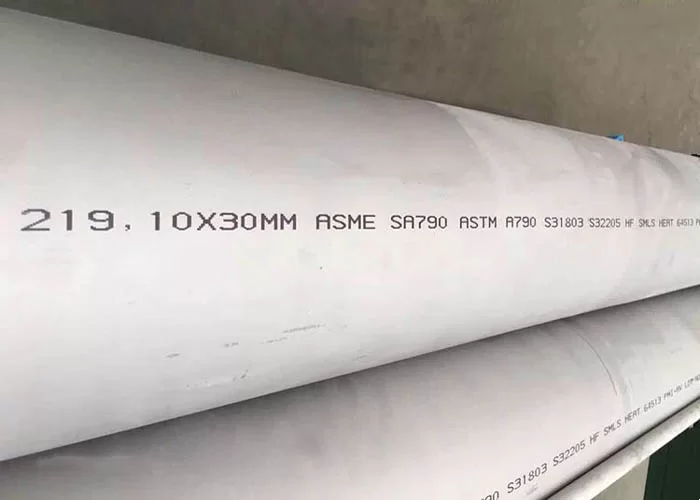

In the competitive landscape of industrial metallurgy, the selection of piping material is rarely a mere logistical decision; it is a commitment to the structural integrity, longevity, and safety of an entire engineering ecosystem. Our ASTM A276 Type 304 and 304L Stainless Steel Pipes represent the pinnacle of austenitic excellence, engineered specifically for those who refuse to compromise on material purity and mechanical reliability.

The Alchemy of Resilience: Chemical Precision

The legendary status of Type 304—the “18-8” stainless steel—is rooted in its precise chemical equilibrium. By maintaining a minimum of 18% Chromium and 8% Nickel, our pipes cultivate a resilient, self-healing passive oxide layer that acts as an impenetrable shield against atmospheric corrosion and oxidizing environments.

For applications involving heavy welding, our Type 304L (Low Carbon) variant is the definitive solution. By restricting carbon content to a maximum of 0.03%, we effectively eliminate the risk of chromium carbide precipitation during the welding process. This prevents “sensitization” at the heat-affected zone, ensuring that the pipe remains as corrosion-resistant at its joints as it is in its body.

Table 1: Chemical Composition Limits (ASTM A276)

| Element | Type 304 (wt%) | Type 304L (wt%) |

| Carbon (C) | 0.08 max | 0.03 max |

| Manganese (Mn) | 2.00 max | 2.00 max |

| Chromium (Cr) | 18.0 – 20.0 | 18.0 – 20.0 |

| Nickel (Ni) | 8.0 – 11.0 | 8.0 – 12.0 |

| Silicon (Si) | 1.00 max | 1.00 max |

| Phosphorus (P) | 0.045 max | 0.045 max |

Thermal Integrity and Microstructural Stability

The performance of a stainless steel pipe is determined long before it reaches the field; it is forged in the rigors of heat treatment. Our ASTM A276 products undergo a rigorous Solution Annealing process. By heating the material to temperatures exceeding $1040^{\circ}C$ and following with a rapid quench, we dissolve any secondary phases and “lock” the austenitic grain structure into its most stable, ductile state. This ensures that the pipes are free from internal stresses and possess a uniform grain size, which is critical for consistent performance under pressure.

Table 2: Heat Treatment Requirements

| Condition | Annealing Temperature (Min) | Cooling Method |

| Solution Treated | $1900^{\circ}F$ [$1040^{\circ}C$] | Rapid Water Quench or Forced Air |

Mechanical Superiority: Strength Meets Ductility

Whether operating in cryogenic temperatures or high-heat environments, our pipes provide a formidable combination of high tensile strength and exceptional elongation. The inherent toughness of the FCC (Face-Centered Cubic) crystal structure means that unlike ferritic steels, our 304/304L pipes do not undergo a ductile-to-brittle transition, making them the safest choice for liquid gas transport and volatile chemical processing.

Table 3: Mechanical Property Benchmarks

| Property | Type 304 | Type 304L |

| Tensile Strength, min | 75 ksi [515 MPa] | 70 ksi [485 MPa] |

| Yield Strength (0.2% Offset) | 30 ksi [205 MPa] | 25 ksi [170 MPa] |

| Elongation (in 50mm, min) | 40% | 40% |

| Hardness (Brinell, max) | 201 HBW | 201 HBW |

Why Partner With Us?

Our ASTM A276 Type 304/304L pipes are more than just conduits; they are the result of decades of metallurgical refinement.

-

Dual Certification: Most of our stock is dual-certified as both 304 and 304L, offering the higher strength of 304 with the superior weldability of 304L.

-

Surface Excellence: We utilize advanced pickling and passivation techniques to ensure a pristine surface finish, maximizing the life of the passive film.

-

Global Compliance: Fully compliant with ASTM, ASME, and EN standards, ensuring seamless integration into international projects.

From pharmaceutical cleanrooms to offshore oil rigs, our stainless steel pipes provide the silent, enduring strength that modern industry demands.

Would you like me to provide a detailed corrosion resistance guide comparing these pipes against specific chemical agents common in your industry?

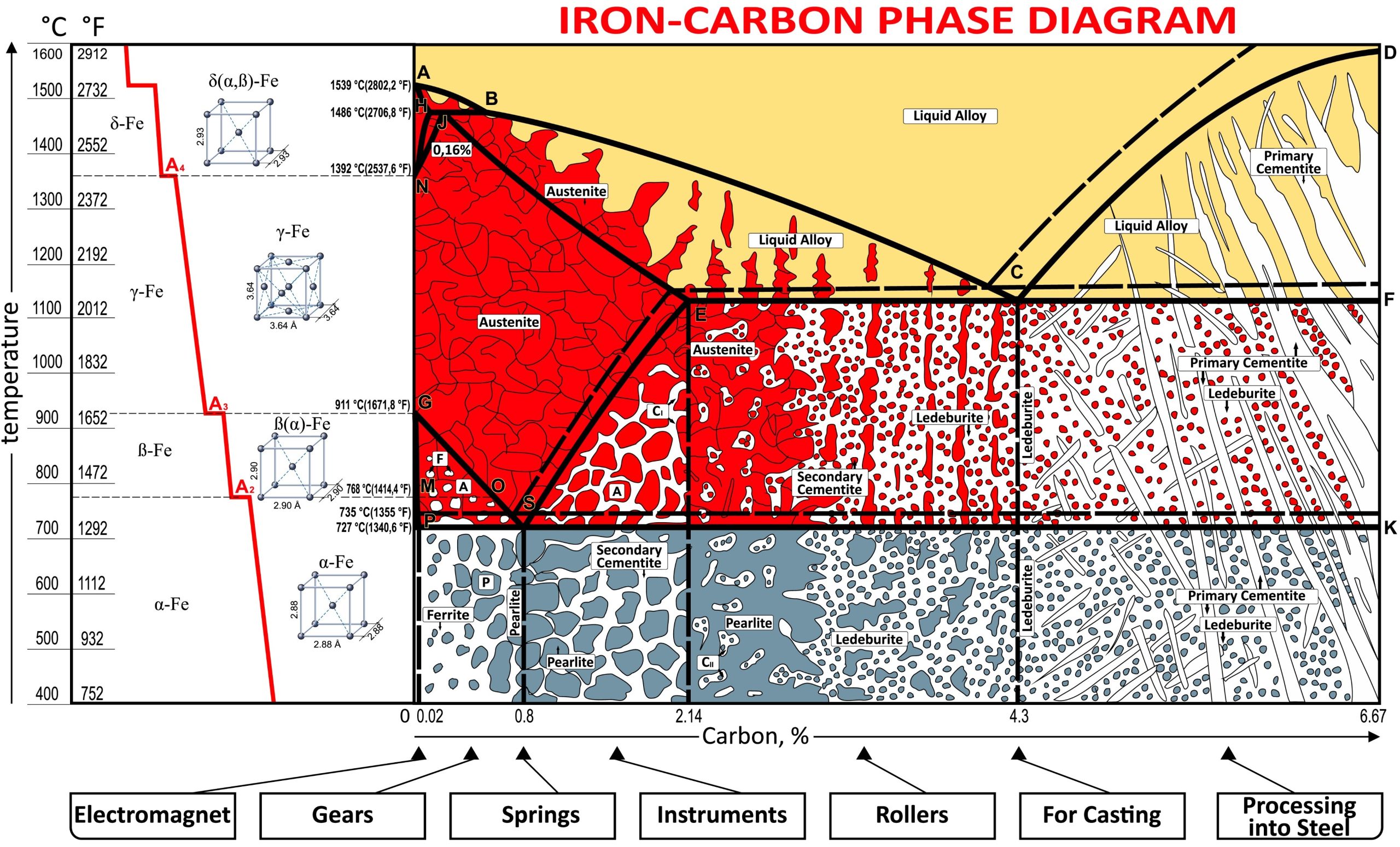

When we step into the world of metallurgical engineering, particularly the realm defined by ASTM A276 Type 304 and 304L, we aren’t just looking at pieces of hollow metal or rigid specifications; we are looking at the refined evolution of the 18-8 stainless steel family which has essentially built the modern industrial landscape. To understand these materials, one must first appreciate the subtle dance between carbon levels and corrosion resistance, because while 304 and 304L are often spoken of in the same breath, the “L” denotes a critical lower carbon threshold—specifically a maximum of 0.03%—that dictates how the steel behaves during the thermal trauma of welding. When we manufacture or specify ASTM A276, which technically covers hot-finished or cold-finished bars including rounds, squares, and hexagons, and apply its logic to the piping and tubular structures our company produces, we are committing to a standard of austenitic stability. The austenitic structure, characterized by its face-centered cubic (FCC) lattice, is what gives these pipes their remarkable toughness and ductility even at cryogenic temperatures, a feat that ferritic or martensitic steels simply cannot replicate without becoming brittle.

The chemical composition is the DNA of the pipe, and in the case of 304/304L, the chromium-nickel balance is the primary architect of the passive film. Chromium, usually sitting between 18% and 20%, is the element that reacts with atmospheric oxygen to form a microscopic, self-healing layer of chromium oxide that prevents further oxidation. However, the presence of Nickel (8% to 12%) is what truly stabilizes the austenite phase, ensuring that the material remains non-magnetic in its annealed state and providing enhanced resistance to reducing environments. If we look closer at the carbon content, we see the primary differentiator: in standard 304, the carbon can go up to 0.08%, which is perfectly fine for many applications, but during welding, this carbon tends to migrate to the grain boundaries and react with chromium to form chromium carbides. This phenomenon, known as sensitization, leaves the adjacent areas “chromium-depleted,” making the pipe vulnerable to intergranular corrosion. This is why our 304L variant is so vital for heavy-gauge welded structures; by keeping carbon low, we suppress carbide precipitation and maintain the integrity of the passive layer right up to the weld bead.

Table 1: Chemical Composition Limits (ASTM A276/A276M)

| Element | Type 304 (wt%) | Type 304L (wt%) |

| Carbon (C) | 0.08 max | 0.03 max |

| Manganese (Mn) | 2.00 max | 2.00 max |

| Phosphorus (P) | 0.045 max | 0.045 max |

| Sulfur (S) | 0.030 max | 0.030 max |

| Silicon (Si) | 1.00 max | 1.00 max |

| Chromium (Cr) | 18.0 to 20.0 | 18.0 to 20.0 |

| Nickel (Ni) | 8.0 to 11.0 | 8.0 to 12.0 |

| Nitrogen (N) | 0.10 max | 0.10 max |

Moving into the mechanical performance and the thermodynamic history of these pipes, we must discuss the heat treatment process, specifically solution annealing. For ASTM A276 materials, the goal of heat treatment isn’t to harden the steel—since austenitic grades cannot be hardened by heat treatment—but rather to dissolve any precipitates and relieve the internal stresses induced during the forming or cold-working processes. We typically heat the material to a range between $1040^{\circ}C$ and $1120^{\circ}C$ followed by a rapid quench in water or air. This rapid cooling is non-negotiable because it “freezes” the carbon in a solid solution, preventing it from having the time to find chromium and form those pesky carbides we mentioned earlier. If the cooling is too slow, we risk losing the very corrosion resistance we worked so hard to achieve. For our pipes, this ensures a homogenous microstructure that provides uniform mechanical properties throughout the length of the product.

Table 2: Heat Treatment Requirements

| Condition | Process Type | Temperature Range | Cooling Method |

| Annealed | Solution Treatment | $1900^{\circ}F$ [$1040^{\circ}C$] minimum | Rapid water quench or air cool |

The mechanical integrity of Type 304 and 304L is defined by a balance of strength and extreme elongation. While 304L has a slightly lower yield strength due to its lower carbon content (carbon acts as an interstitial strengthener), both grades offer excellent work-hardening characteristics. In many engineering applications, the tensile strength of 515 MPa and yield of 205 MPa for 304 are the benchmarks. However, the real “magic” of these pipes lies in their elongation percentages, often exceeding 40%. This means the pipe can undergo significant deformation before failure, a critical safety feature in high-pressure or seismic-sensitive environments. When we test these materials in our labs, we are looking for that classic stress-strain curve where the plastic deformation region is broad and smooth, indicating a material that is forgiving and reliable under the unpredictable stresses of industrial fluid transport.

Table 3: Tensile and Hardness Requirements

| Grade | Tensile Strength, min (ksi [MPa]) | Yield Strength, 0.2% offset, min (ksi [MPa]) | Elongation in 2 in. [50mm], min (%) | Brinell Hardness, max (HBW) |

| Type 304 | 75 [515] | 30 [205] | 40 | 201 |

| Type 304L | 70 [485] | 25 [170] | 40 | 201 |

Beyond the numbers, the technical superiority of our ASTM A276 Type 304/304L pipes is found in their versatility across diverse pH ranges and temperatures. Whether it is in the food and beverage industry where hygiene is paramount and the smooth surface finish prevents bacterial colonization, or in the chemical processing sector where resistance to nitric acid is required, these pipes perform. We must also consider the role of surface finish; a pipe that is properly pickled and passivated will always outperform a raw-finish pipe because the removal of “tramp iron” and scale allows the chromium oxide layer to form flawlessly. In the context of long-term lifecycle costs, choosing 304 or 304L is an investment in durability. The lack of maintenance requirements and the nearly infinite recyclability of the material align it with modern sustainability goals, making it not just a choice of engineering necessity, but one of environmental responsibility. As we continue to push the boundaries of what these alloys can do, particularly in the integration of “Dual Certified” materials (meeting both 304 and 304L specs), we provide our clients with the maximum allowable strength of 304 and the superior weldability of 304L, ensuring that every joint, flange, and length of pipe stands as a testament to metallurgical excellence.