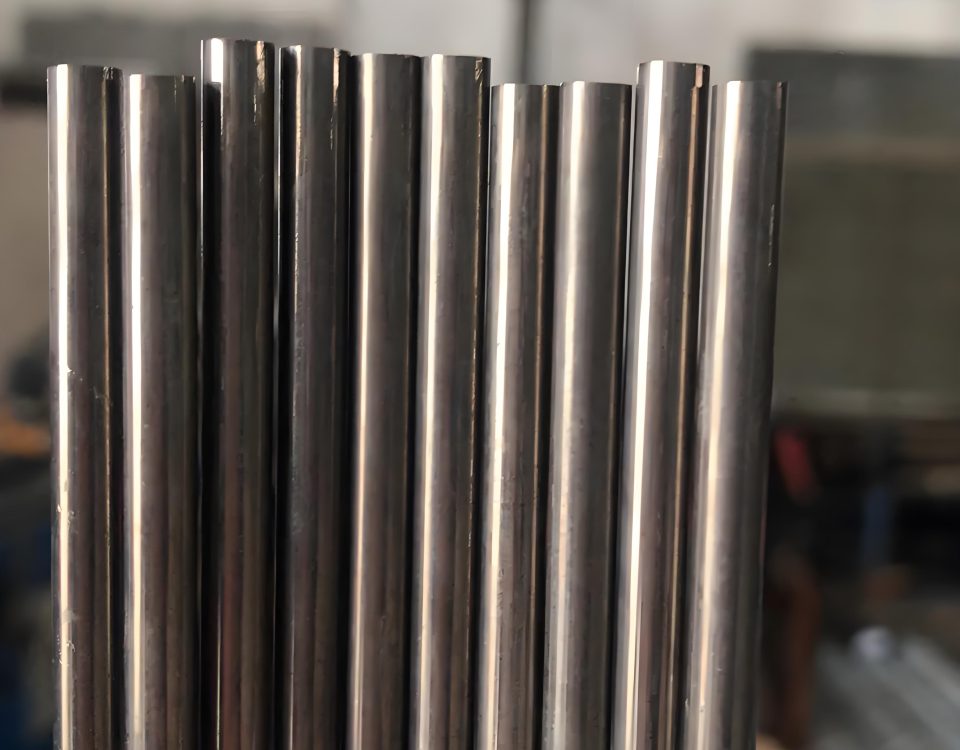

Super Duplex Alloy UNS S32750 steel pipes | F53 / 1.4410 / 32750 / Alloy 2507

July 24, 2025

Nickel Alloy 718 (Inconel® 718, UNS N07718, W. Nr. 2.4668) Steel Pipe

August 8, 2025

Incoloy 901 Nickel Alloy Steel Pipe (UNS N09901/DIN 1.4898): A Comprehensive Overview

Introduction to Incoloy 901

Incoloy 901, designated as UNS N09901 or DIN 1.4898, is a high-performance nickel-iron-chromium superalloy renowned for its exceptional mechanical strength, creep resistance, and corrosion resistance at elevated temperatures. Developed for demanding applications, particularly in aerospace and gas turbine industries, this alloy combines a robust composition with unique metallurgical properties to deliver reliability in extreme environments. Its ability to withstand high temperatures, resist corrosive atmospheres, and maintain structural integrity under stress makes it a preferred choice for critical components such as turbine discs, shafts, and seamless pipes. Incoloy 901’s versatility extends to its use in seamless and welded pipes, which are integral to high-temperature systems where durability and performance are paramount.

The alloy’s composition, featuring nickel, iron, chromium, titanium, aluminum, and molybdenum, is carefully engineered to achieve a balance of strength and workability. The substantial iron content enhances its forging characteristics, while titanium and aluminum contribute to precipitation hardening, ensuring high yield strength up to approximately 1110°F (600°C). Molybdenum provides solid-solution strengthening, further bolstering the alloy’s ability to resist deformation under prolonged stress. These attributes make Incoloy 901 pipes indispensable in applications requiring resistance to creep, fatigue, and oxidation in harsh operating conditions.

This article provides a detailed exploration of Incoloy 901 nickel alloy steel pipes, covering their material composition, mechanical properties, corrosion resistance, and practical applications. A comprehensive table of parameters is included to summarize key technical data, offering a clear reference for engineers, manufacturers, and researchers. By delving into the alloy’s characteristics and performance, this article aims to underscore its significance in modern industrial applications.

Incoloy 901 (UNS N09901/Din 1.4898)

Incoloy 901 Chemical composition:

| Alloy | % | Ni | Cu | Al | Fe | Ti | Co | Mn | S | C | Si | P | Cr | Mo | B |

| Incoloy 901 | Min. | 40.0 | 2.35 | 11.0 | 5.0 | 0.01 | |||||||||

| Max. | 45.0 | 0.50 | 0.35 | Balance | 3.10 | 1.0 | 1.0 | 0.03 | 0.10 | 0.60 | 0.03 | 14.0 | 7.0 | 0.02 |

Incoloy 901 Physical properties:

| Density | 8.14 g/cm3 |

| Melting point | 1280-1345ºC |

Incoloy 901 minimum mechanical properties in the room temperature:

| Status | Tensile strength Rm N/mm2 |

Yield strength RP0.2N/mm2 |

Elongation A5 % |

| Incoloy 901 | 1034 | 689 | 12 |

Chemical Composition and Material Analysis

Incoloy 901 is an austenitic age-hardening alloy based on a nickel-iron-chromium matrix, with strategic additions of titanium, aluminum, molybdenum, and trace elements like boron and carbon. The precise chemical composition is critical to its performance, as each element plays a specific role in enhancing the alloy’s properties. The typical composition, expressed as weight percentages, includes approximately 40.0–45.0% nickel, 11.0–14.0% chromium, 5.0–7.0% molybdenum, 2.35–3.10% titanium, 0.1–0.6% aluminum, and a balance of iron, with minor amounts of carbon (≤0.1%), manganese (≤1.0%), silicon (≤0.6%), sulfur (≤0.03%), and boron (≤0.02%).

Nickel provides the foundation for the alloy’s corrosion resistance and high-temperature stability, enabling it to perform reliably in aggressive environments such as jet engine exhausts. Chromium enhances oxidation resistance, forming a protective oxide layer that shields the material from scaling at elevated temperatures. Molybdenum contributes to solid-solution strengthening, improving resistance to creep and pitting corrosion in chloride-rich environments. Titanium and aluminum are key to the alloy’s precipitation hardening mechanism, forming the metastable γ” [Ni3(Ti, Al)] phase, which significantly boosts yield strength. The small amount of boron enhances grain boundary strength, reducing the risk of intergranular cracking during high-temperature exposure. The low carbon content minimizes carbide precipitation, stabilizing the microstructure during long-term use.

The material’s austenitic structure ensures excellent toughness and ductility, even at elevated temperatures, while the controlled addition of aluminum inhibits the transformation of the γ” phase to the less desirable η-Ni3Ti phase, maintaining long-term stability. This carefully balanced composition enables Incoloy 901 to combine high strength with good forging characteristics, making it suitable for manufacturing seamless pipes that meet stringent industry standards, such as those specified by ASME SB407 for nickel-iron-chromium alloys.

Mechanical Properties of Incoloy 901 Pipes

The mechanical properties of Incoloy 901 nickel alloy steel pipes are a defining feature, making them ideal for high-stress applications. The alloy’s high yield strength, creep resistance, and fatigue resistance are achieved through a combination of solid-solution strengthening and precipitation hardening. At room temperature, Incoloy 901 exhibits a minimum tensile strength of approximately 1150 MPa (167 ksi) and a yield strength of around 900 MPa (130 ksi), with an elongation of 12–15%. At elevated temperatures up to 1110°F (600°C), the alloy retains significant strength, with creep rupture strength exceeding that of many stainless steels.

The precipitation hardening process, driven by the formation of γ” phases, enhances the alloy’s ability to resist deformation under sustained loads, a critical factor for components like turbine discs and pipes in gas turbines. The creep resistance is particularly notable, with the alloy maintaining structural integrity under prolonged exposure to high temperatures and stresses. Fatigue resistance is also a key attribute, as Incoloy 901 pipes can endure cyclic loading without significant degradation, making them suitable for dynamic environments such as aerospace propulsion systems.

The alloy’s toughness and ductility allow it to be formed into seamless pipes through hot working processes, typically conducted between 1850°F and 2050°F (1010°C–1121°C). Light hot working can continue down to 1600°F (871°C), but temperatures below this are avoided to prevent cracking. Post-forming heat treatments, such as solution annealing followed by aging, optimize the microstructure for maximum strength and stability. These mechanical properties ensure that Incoloy 901 pipes deliver reliable performance in demanding applications, from high-pressure fluid transport to structural components in extreme environments.

Corrosion Resistance Characteristics

Incoloy 901 is engineered to offer robust corrosion resistance, particularly in the harsh atmospheres encountered in jet engine operations and industrial gas turbines. The alloy’s high nickel and chromium content forms a protective oxide layer that resists oxidation and scaling at temperatures up to 1110°F (600°C). While its scaling resistance is slightly lower than that of stainless steels like Types 309 and 310, Incoloy 901 excels in environments with complex corrosive agents, including sulfur-containing gases and chloride-rich conditions.

The presence of molybdenum enhances the alloy’s resistance to pitting and crevice corrosion, which are critical concerns in applications involving exposure to seawater or acidic media. This makes Incoloy 901 pipes suitable for use in marine exhaust systems and chemical processing plants, where localized corrosion can compromise structural integrity. The alloy also demonstrates good resistance to stress-corrosion cracking (SCC), a common failure mode in high-temperature environments with chloride ions. This is particularly important for seamless pipes used in high-pressure systems, where tensile stresses and corrosive media coexist.

Incoloy 901’s corrosion resistance is further enhanced by its stable microstructure, which resists sensitization and intergranular corrosion during prolonged exposure to elevated temperatures. The low carbon content and boron additions minimize the formation of deleterious phases, ensuring long-term durability. While not as resistant to highly oxidizing acids like nitric acid compared to alloys like Incoloy 825, Incoloy 901 performs admirably in moderately oxidizing and reducing environments, making it a versatile choice for applications requiring both corrosion resistance and mechanical strength.

Manufacturing and Processing of Incoloy 901 Pipes

The production of Incoloy 901 nickel alloy steel pipes involves sophisticated metallurgical and manufacturing processes to achieve the desired properties. The alloy is typically forged between 1850°F and 2050°F (1010°C–1121°C) to ensure optimal workability without compromising the microstructure. Rapid heating through the precipitation hardening range is critical to prevent undesirable phase transformations. Light hot working can be performed down to 1600°F (871°C), but temperatures below this are avoided to prevent cracking due to reduced ductility.

Seamless pipes are produced through processes like extrusion or rotary piercing, followed by heat treatments to enhance mechanical properties. Solution annealing, typically conducted at 2000°F (1093°C) followed by rapid cooling, dissolves precipitates and prepares the alloy for aging. Aging treatments at 1300–1400°F (704–760°C) promote the formation of γ” phases, maximizing strength and creep resistance. Welded pipes, while less common due to the alloy’s challenging weldability, can be fabricated using inert-gas-arc welding, with all welding performed in the solution-treated condition to minimize cracking.

The alloy’s substantial iron content facilitates forging, allowing manufacturers to produce pipes with consistent wall thickness and smooth surfaces. Cold working is possible for smaller diameter pipes, but re-solution treatment is required before welding to restore ductility. The resulting pipes meet stringent standards, such as ASME SB407, ensuring compliance with industry requirements for dimensions, tolerances, and performance. These manufacturing processes underscore Incoloy 901’s suitability for high-precision applications in aerospace, energy, and chemical processing.

Applications of Incoloy 901 Pipes

Incoloy 901 nickel alloy steel pipes are widely used in industries requiring materials that can withstand extreme temperatures, mechanical stresses, and corrosive environments. The aerospace sector is a primary consumer, where Incoloy 901 pipes are employed in gas turbine engines for components such as turbine rotors, compressor discs, and exhaust systems. The alloy’s high strength and creep resistance at temperatures up to 1110°F (600°C) make it ideal for these applications, where reliability under cyclic loading and thermal stress is critical.

In the energy sector, Incoloy 901 pipes are used in industrial gas turbines for power generation, particularly in high-temperature fluid transport systems. Their ability to resist oxidation and maintain structural integrity under prolonged exposure to hot gases ensures long service life. The alloy’s corrosion resistance also makes it suitable for chemical processing plants, where pipes may transport aggressive fluids or operate in environments with sulfur or chloride compounds. Marine applications, such as exhaust systems for naval vessels, benefit from the alloy’s resistance to seawater-induced corrosion.

Other applications include high-temperature bolting, seals, and structural components in advanced engineering systems. The alloy’s versatility in seamless and welded pipe forms allows it to be tailored to specific requirements, from small-diameter tubing to large-scale piping systems. Its combination of mechanical strength, corrosion resistance, and forgeability ensures that Incoloy 901 pipes meet the rigorous demands of modern industrial applications, contributing to efficiency and safety in critical operations.

Technical Specifications and Parameter Table

To provide a clear reference for engineers and manufacturers, the following table summarizes the key parameters of Incoloy 901 nickel alloy steel pipes, including chemical composition, mechanical properties, and physical characteristics.

| Parameter | Specification |

|---|---|

| Alloy Designation | Incoloy 901 (UNS N09901, DIN 1.4898, Werkstoff 2.4662) |

| Chemical Composition | Ni: 40.0–45.0%, Cr: 11.0–14.0%, Mo: 5.0–7.0%, Ti: 2.35–3.10%, Al: 0.1–0.6%, Fe: Balance, C: ≤0.1%, Mn: ≤1.0%, Si: ≤0.6%, S: ≤0.03%, B: ≤0.02% |

| Density | 8.14 g/cm³ (0.294 lb/in³) |

| Tensile Strength (Room Temp) | ≥1150 MPa (167 ksi) |

| Yield Strength (Room Temp) | ≥900 MPa (130 ksi) |

| Elongation (Room Temp) | 12–15% |

| Creep Rupture Strength | High at 1110°F (600°C), specific values depend on heat treatment |

| Corrosion Resistance | Good in jet engine atmospheres, resistant to pitting and stress-corrosion cracking |

| Oxidation Resistance | Effective up to 1110°F (600°C), slightly lower scaling resistance than Types 309/310 stainless steel |

| Hot Working Temperature | 1850–2050°F (1010–1121°C), light work down to 1600°F (871°C) |

| Heat Treatment | Solution annealing at 2000°F (1093°C), aging at 1300–1400°F (704–760°C) |

| Weldability | Difficult, requires inert-gas-arc welding in solution-treated condition |

| Standards | ASME SB407, ASTM B163, AMS 5660, AMS 5661, ISO 9723, ISO 9725 |

| Applications | Gas turbine components, chemical processing, marine exhaust systems |

This table serves as a quick reference for the alloy’s capabilities, ensuring that designers and engineers can select Incoloy 901 pipes for applications requiring specific performance criteria.

Comparison with Other Nickel Alloys

Incoloy 901 is often compared to other nickel-based superalloys, such as Inconel 625 and Incoloy 825, due to their overlapping applications in high-temperature and corrosive environments. Inconel 625, with a higher nickel content (≥58%) and additions of niobium, offers superior corrosion resistance in highly oxidizing environments, such as nitric acid, but is more expensive due to its composition. Incoloy 901, with its substantial iron content, provides a cost-effective alternative with comparable strength and good corrosion resistance for jet engine atmospheres. Its creep resistance is particularly advantageous for applications requiring long-term stability under stress.

Incoloy 825, another nickel-iron-chromium alloy, excels in resisting sulfuric and phosphoric acids due to its copper and molybdenum content. However, its lower strength at high temperatures makes it less suitable for applications like turbine discs, where Incoloy 901’s precipitation hardening provides a significant advantage. The alloy’s forging characteristics also set it apart, as its iron content allows for easier processing compared to high-nickel alloys like Inconel 718, which can be more challenging to work.

The choice between Incoloy 901 and other alloys depends on the specific requirements of the application. For environments requiring high strength and creep resistance up to 1110°F (600°C), Incoloy 901 is often preferred. For applications involving extreme corrosion, such as in nuclear fuel reprocessing, alloys like Incoloy 825 or Inconel 625 may be more suitable. Understanding these trade-offs allows engineers to select the optimal material for their needs.

Challenges and Limitations

Despite its impressive properties, Incoloy 901 has certain limitations that must be considered during design and manufacturing. One primary challenge is its weldability, as the alloy is prone to cracking during welding due to its high strength and precipitation-hardening characteristics. Welding must be performed in the solution-treated condition using inert-gas-arc methods, and post-weld heat treatments are often required to restore properties. This complexity can increase production costs and requires skilled expertise.

Another limitation is the alloy’s slightly lower scaling resistance compared to stainless steels like Types 309 and 310. While it performs well in jet engine atmospheres, prolonged exposure to highly oxidizing conditions above 1110°F (600°C) may lead to surface degradation. Engineers must carefully assess the operating environment to ensure the alloy’s performance aligns with expectations. Additionally, the alloy’s high strength can make cold working more difficult, necessitating precise control during manufacturing to avoid defects.

The cost of Incoloy 901, while lower than that of high-nickel alloys like Inconel 625, is still significant due to its complex composition and processing requirements. For applications where cost is a primary concern, less expensive materials like stainless steel may be considered, though they may not match Incoloy 901’s high-temperature performance. By understanding these challenges, manufacturers can implement strategies to mitigate limitations, such as optimizing heat treatments or selecting alternative alloys for less demanding conditions.

Future Trends and Innovations

The demand for high-performance materials like Incoloy 901 is expected to grow as industries such as aerospace, energy, and chemical processing continue to push the boundaries of technology. Advances in manufacturing techniques, such as additive manufacturing and precision forging, are likely to enhance the production of Incoloy 901 pipes, allowing for more complex geometries and improved material efficiency. Research into optimizing heat treatment processes could further enhance the alloy’s mechanical properties, extending its service life in extreme conditions.

Emerging applications in renewable energy, such as concentrated solar power and geothermal systems, may also drive demand for Incoloy 901 pipes due to their ability to withstand high temperatures and corrosive environments. Additionally, efforts to improve the alloy’s weldability through modified compositions or advanced welding techniques could expand its use in welded pipe systems, reducing production costs and increasing versatility.

Sustainability is another area of focus, with manufacturers exploring ways to reduce the environmental impact of producing nickel alloys. Recycling of Incoloy 901 scrap and the development of more energy-efficient processing methods could align the alloy with greener industrial practices. As industries strive for higher efficiency and durability, Incoloy 901’s unique combination of properties positions it as a material of choice for future innovations, ensuring its relevance in cutting-edge applications.

Incoloy 901 nickel alloy steel pipes (UNS N09901/DIN 1.4898) represent a pinnacle of materials engineering, offering a remarkable balance of high strength, creep resistance, and corrosion resistance for demanding applications. Its carefully engineered composition, featuring nickel, iron, chromium, titanium, and molybdenum, delivers exceptional performance in high-temperature environments, making it a cornerstone of aerospace, energy, and chemical processing industries. The alloy’s mechanical properties, including high yield strength and fatigue resistance, ensure reliability in critical components like turbine discs and seamless pipes.

The corrosion resistance of Incoloy 901, while slightly less robust than some stainless steels in scaling resistance, is well-suited to jet engine atmospheres and chloride-rich environments. Its manufacturing versatility, facilitated by good forging characteristics, allows for the production of high-quality seamless pipes that meet rigorous industry standards. Despite challenges such as difficult weldability and higher costs compared to standard steels, Incoloy 901’s advantages make it indispensable for applications where performance cannot be compromised.

As industries evolve, Incoloy 901 is poised to remain a vital material, with ongoing innovations in processing and applications expanding its utility. The comprehensive parameter table provided in this article serves as a valuable resource for engineers and manufacturers, highlighting the alloy’s capabilities and guiding its use in real-world applications. By understanding its properties, limitations, and potential, stakeholders can leverage Incoloy 901 to drive advancements in technology and engineering, ensuring safety, efficiency, and durability in the most challenging environments.