Wire Wound Screen (Filter Pipe)

February 17, 2023

The inquiry for flanges

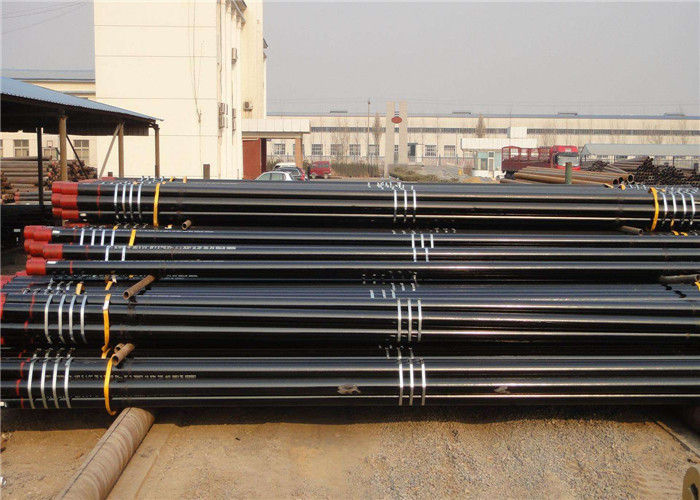

March 9, 2023Steel pipe production is a complex process that requires a combination of old-fashioned craftsmanship and modern technology. The process begins with the selection of the raw materials and ends with the delivery of the finished product. The entire process is divided into several stages, each Of which is essential in creating the highest quality steel pipes.

The first stage in steel pipe production is the selection of the raw materials. Steel pipe makers usually purchase steel in coils, although some manufacturers do process slabs of steel. The coils are cut into strips of the desired width and shape, which are then fur processed. The shape of the steel pipe can vary, depending on the final application. For example, a pipe used for a gas line may have a different shape than one used for water pipes.

The strips are then subject to a series of operations that turn them into round pipe. The strips are first heated in a furnace and then passed through a series of rollers. The rollers reduce the thickness of the steel strip and shape it into a round pipe .

The next stage in the process is welding. Steel pipe makers use several methods for welding including arc welding, resistance welding, and submerged arc welding. Each method has its advantages and disadvantages depending on the application. For example, arc welding is a fast and economical option, but it is not suitable for all applications.

The next step in steel pipe production is the addition of coatings and other treatments. The most common treatment is galvanization, which is the application of a zinc coating to the surface of the steel pipe. This coating helps to protect the pipe from corrosion and other environmental damage. Other coatings, such as epoxy and polyurethane, may also be applied to the pipe to improve its performance.

The final step in steel pipe production is the inspection and testing of the finished product. This is done to ensure that the pipe meets all of the applicable standards and specifications. The pipes are tested for strength, durability, and corrosion resistance, as well as for their size, shape, and wall thickness. The pipes are also inspected for any imperfections or damage that might have occurred during the manufacturing process.

Steel pipe production is a complex process that requires many years of experience and expertise. With the right combination of old-fashioned craftsmanship and modern technology, steel pipe makers can create high-quality pipes that are reliable, durable, and safe. With the right level of experience, steel pipe makers can ensure that their products meet the highest standards and specifications. With the right attention to detail, steel pipe makers can ensure that their products are of the highest quality and are safe for use in a variety of applications.

The steel pipe factory has been a staple of the manufacturing industry for four years, providing quality steel pipes to a variety of industries. During this time, the factory has seen a lot of growth and development, from the introduction of new technologies and processes to the expansion of its customer base. This article will explore the steel pipe factory’s four years of manufacturing experience, looking at how the company has evolved and what it has achieved.

Since its inception, the steel pipe factory has been dedicated to producing the highest quality steel pipes for a variety of applications. The company manufactures a range of standard and custom steel pipes using advanced cold-forming and hot-forming technologies. All pipes are manufactured from raw materials that meet stringent quality standards, ensuring the pipes are durable and reliable. The factory has also adopted a range of advanced techniques, such as welding and threading, to ensure the pipes are of the highest quality.

In addition to its commitment to producing high-quality steel pipes, the steel pipe factory has also been dedicated to providing excellent customer service. This is evident in the factory’s focus on providing timely delivery and competitive prices. The company has worked hard to build strong relationships with its customers, ensuring that all orders are fulfilled quickly and accurately. The factory also provides a comprehensive range of services, including on-site installation and maintenance, to ensure that customers have the best experience possible.

Over the past four years, the steel pipe factory has also seen a number of changes and improvements. In order to stay ahead of the competition, the company has adopted advanced production techniques, such as robotic welding and automated cutting. This has enabled the factory to produce higher-quality pipes with greater consistency and efficiency. The factory has also invested in state-of-the-art equipment, such as robotic arms and automated inspection machines, to ensure that all pipes meet strict quality standards.

In order to ensure that its customers have the best experience possible, the steel pipe factory also provides a range of after-sales services. The company offers technical support and advice, as well as on-site installation and maintenance. The factory also provides training and education to its customers, helping them to better understand the processes and technologies used to produce steel pipes.

During its four years of operation, the steel pipe factory has also experienced significant growth. The company has expanded its customer base, increasing its presence in a number of markets. In addition, the factory has also increased its production capacity, allowing it to meet the rising demand for steel pipes. The company has also seen a marked improvement in its efficiency, with production times becoming shorter and customer satisfaction increasing.

The steel pipe factory has had a successful four years of manufacturing experience, developing and expanding its customer base, investing in advanced production techniques, and providing excellent customer service. The factory has also seen a marked improvement in its efficiency, and customer satisfaction increasing. As the steel pipe factory continues to grow and develop, it is sure to remain a leader in the industry for many years to come.

-steel-pipe.jpg)