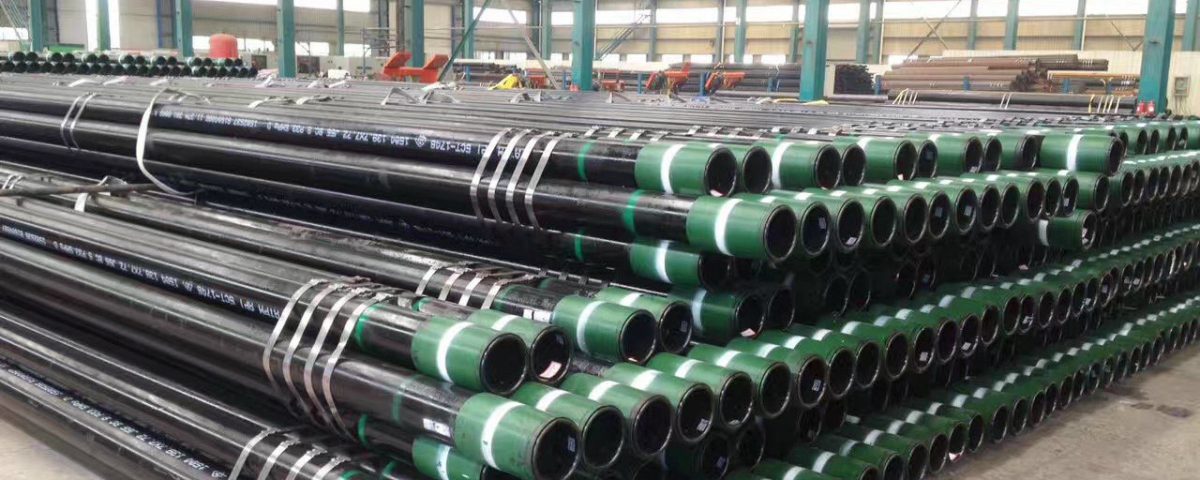

K55 Casing pipe Project for Azerbaijan and Kazakhstan oilfield

April 28, 2018

casing seamless steel API 5CT K-55, 8-5/8″, 9 5/8″ For Cairo, Egypt

May 3, 2018Product Number: Sumitomo Metal SM 2535 / Tubing 23 Lb/ft / OD: 7″ / ID: 6.366″ / Tubing 26 Lb/ft / OD: 7″ / ID: 6.276″.

TECHNICAL SPECIFICATIONS:

- General Definition of Equipment

1.1 Tubing / Liner

1.1.1.: 28% Cr Material

7” OD tubing, 23, 26 Lb/ft, range II, 100-130 ksi yield strength.

Pup joints 0.75 m, 1 m, 1.25 m, 1.5 m, 3 m and 6 m long with the same specification.

1.2 Accessories

1.2.1.: 28% Cr Material

7” coupling

7” drift caliper (Teflon material).

Pipe dope.

2.Material requirements

2.1 28% CRA

All tubulars and accessories shall be manufactured with corrosion resistance alloy ( Min. pitting index 36) , CRA material ( 25 – 28% Cr , 30 – 35% Ni). Required grade is 110 ksi obtained by cold – working.

Mechanical properties and chemical analysis shall comply with the following requirements :

Mechanical Properties :

|

GRADE YIELD ULTIMATE ELONGATION HARDNESS FINAL STRENGTH TENSILE % MIN. RC MAX. CONDITION STRENGTH |

|

|

Min. 110 ksi 115 ksi 11% 33 Cold work Max. 130 ksi |

|

Chemical Analysis

|

Ni Cr Mo Cu Mn Si P S C Fe N Max max max max max max max |

|

|

29 25 ,28 3 Weight % 1.50 1.00 0.50 0.030 0. 030 0. 030 Remainder 0.20 36.5 27.5 4 |

|

- Quantitiy:

7 in.( OD: 7″ / ID: 6.276″ ) x 26 ppf x 28 to 34 ft. / Total quantity: 24,000 Meters

7 in.( OD: 7″ / ID: 6.366″ ) x 23 ppf x 32 to 38 ft. / Total quantity 63,000 Meters

Pitting Index

The minimum pitting index required is 36. This index is calculated by the following formula : % CR + ( % Mo x 3.3 ) + ( % N x 16 )

This index is requird not only for well corrosion aspects but also to combat strong atmospheric corrosion during storage in the Persian Gulf Area.

– Please, would it be possible to have an quote/ogffer for OCTG Corrosion Resistance Alloy Tubings for Sour Gas Drilling Services ( see details- ATTACHMENT )

in two different Sizes;

- A) 7″ OD x 26 ppf x 28 to 34 ft and Total Quantity : 24,0000 METERS ( Twenty Four Thousands Meters )

- B) 7″ OD x 23 ppf x 32 to 38 ft and Total quantity : 63,000 METERS ( Sixty Three Thousands Meters )

If you need to know : Quote/Offer is requested on FOB Basis, to your Nearest International port along with Technical Sepecification, Delivery Time and Packing Details. please ask us….