REQUIREMENT FOR PIPE & FITTINGS MATERIAL FOR DG Infrastructure Pvt. Ltd.

April 17, 2018

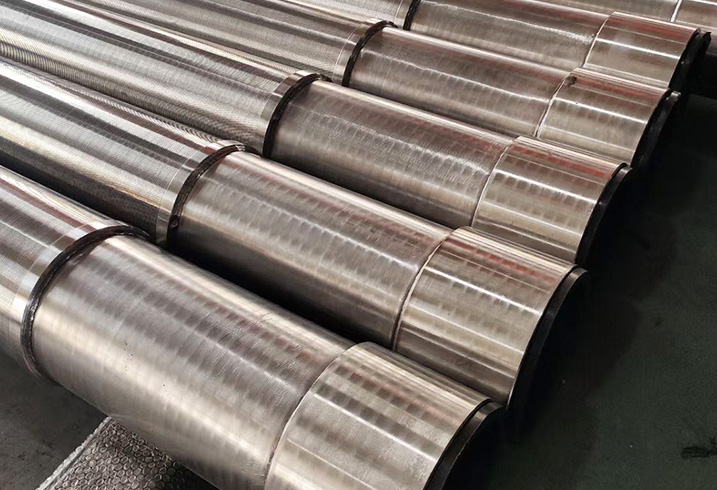

API 5CT PSL casing tubing product specification range

April 20, 2018Wire wrapped sand screen filter – TECHNICAL REQUIREMENTS FOR SAND SCREEN OF OIL WELL ON BELUGA FIELD

1. Purpose and area of application

Sand screen will be run into oil & gas wells to prevent propant and sand out after hydraulic fracturing

jobs (frack pack) in oil well of Beluga field, block 09-3/12. in block 09-3/12.

Design duration of using the equipment – not less 15 years.

Surface condition: Environment temperature up to 45°C, relative humidity up to 100 %.

2. Technical and operating conditions

• Thread type of down hole equipment: API EUE

• Tubing characteristics: as per Specification API 5CT, grade P-110, API EUE thread with

size 2-7/8″ 6.5 PPF; 3-1/2″ 9.3 PPF.

• Casing sizes: 7″ (26-29 PPF), 9-5/8″ (40-53.5 PPF).

• Maximum well depth: 3500m.

• Maximum deviation of well bore: 150100m

• Maximum SBHP and maximum SBHT at mid-depth of:

o Production interval: 380 atm, 248°F.

• Injection interval: 700 atm, 248°F.

• Corrosion conditions: COz up to 1% mol.

• Type of other chemical:

• Acid treatment fluid: 15%-20% HC1. 3% HF.

• Corrosion inhibitor: not available, but will be applied in future.

• Chemical for removing and inhibiting the paraffin wax.

• Chemical for solving and cleaning up the scale.

3. Codes and Standards

• The sand screen manufacturer/supplier is to have an audible quality control system

acceptable for endorsement to ISO 17824:2014 or higher.

• The supplier is required to provide a copy of the QA/QC certificate for the sand screen as

the request of VSP.

•Either in total or in part to use the codes and standards: API 19SS, API 5CT.

• Design validation Grade V1, quality grade Q1.

4. Technical requirements of sand screen

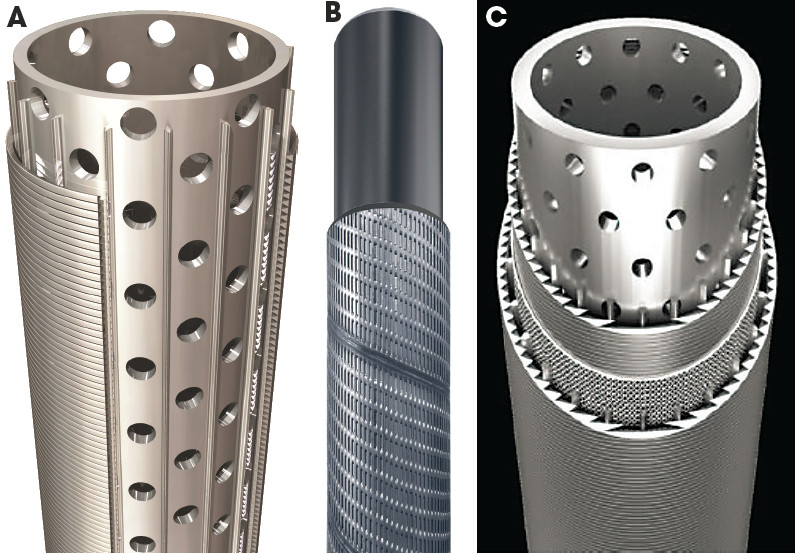

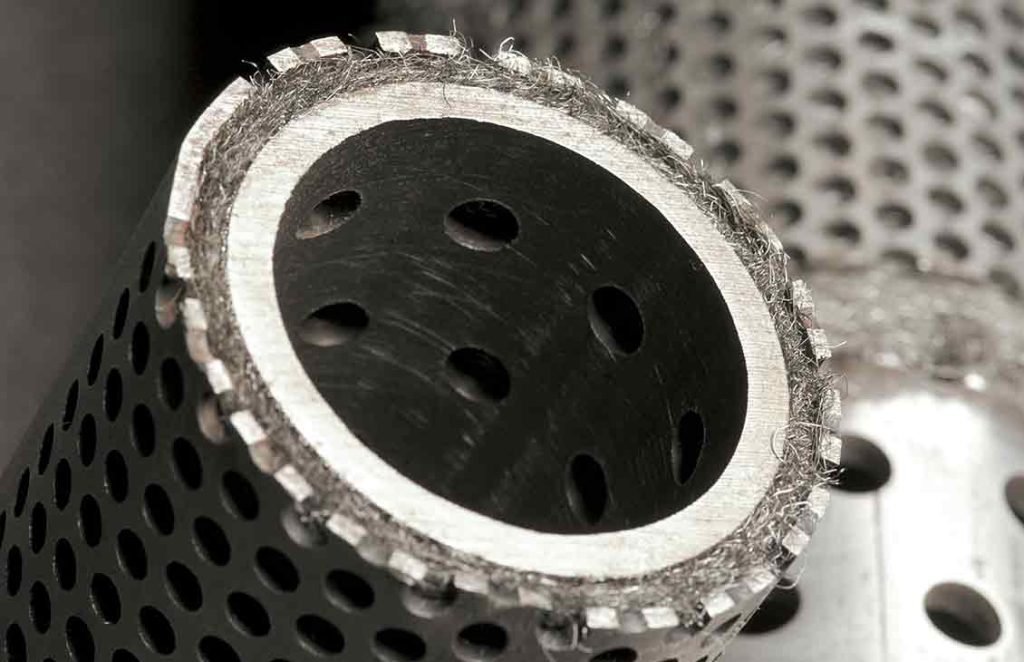

VSP uses single wire-wrapped screen type. Single wire-wrapped screen is the original design

where wire is wrapped around the longitudinal rib wires to form a screen jacket. This jacket is then

slipped over the perforated base pipe and welded at each end to hold the jacket in place. The sand

screen as wire wrapped screen with basic characteristics:

• Base pipe: 4-1/2* # 12.75 PPF.

• Base pipe grade: L-80/N-80

• Connection thread of base pipe: EUE Box x pin

• Base pipe holes per foot, Max OD, Min ID screen: due to standard of base pipe size and the

screen suitable for running smoothly in casing 7″ (26-29 PPF). Hole size (diameter): 0.375″.

Length of pipe: 32-39 ft length

Length of screen: not less than 24 ft

• Screen Adapter Short.

• Number of stainless steel ribs: not less than 25 ribs, rib size: 0.140″, SS316 or better.

• Gauge size of the screen (range of particular size): from 0.006 inch to 0.0118 inch (from 150

micron to 300 micron). Normal size: 0.0079 inch (200 micron).

• The wrap wire and rib is typically 316 stainless material. The wrap wire may be square or it

may be a keystone or triangular cross section. Wire size: 0.140″.

• The wire and ribs are joined by resistance welding, weld at each contact point. Both ends of

screen is slipped over prepared base-pipe and attached by welding each end.

• Burst Resistance and Collapse Resistance: not less than 2800 PSI.

5. The requirements of quantity and shipment

Quantity of the equipment shall be indicated in VSP inquiry, which to be sent to supplier

together with Tender’s invitation. Number of shipments, shipment order, list of the

equipment of each shipment shall be decided in discussion for signing the contract.

• The shipment will be in accordance with international standard for good export.

6. The requirements of packing and marking

The commodities are to be bundled and strapped with metal band with the below quantity and

shall be protected from damage during transportation and handling, which is to be guaranteed by

bidder.

7. Time of delivery and guarantee period.

Delivery time: maximum 12 weeks as from the date of contract signing to the date the Minute

of delivery is approved.

Guarantee period of the equipment: 12 months from the date of putting the equipment into

operation, but not later than 18 months from the date of delivery of the equipment.

8. Supplied Goods Documentation

The tendered should confirm in the proposal that the following documentation is to be submitted

together with cargo to the end-user of J/V “Vietsovpetro”:

• Copy of Certificate of origin.

Copy of Manufacturer’s certificate of compliance stating that the material has been manufactured,

sampled, tested and inspected in accordance with API spec 19SS (or equivalent) and revision date

thereof, to which pipe was manufactured.

Inspection certification of single wire-wrapped screen (screen size, nominal gauge, wrap wire width,

nominal pitch, actual pitch, sereen length…)

9. Documentation for bid

BIDDER is requested to submit a complete of Bidding Documentation, including followings but no

limited:

Description of proposed Goods:

•Bidder shall specify detail specification and steel grade of the proposed sand screen, as

well as the standard which sand screen is manufactured in accordance to (i.e. API Spec

195S or others).

• Drawings, datasheet, catalogue of the screen.

Noted: The name of the origin country must be indicated in the tender proposal and will not be allowed

to write the regions as origin country.

Bidder shall submit copies of following certificates:

• Valid Quality Management System Certificate of compliance with standard ISO

17824:2014 or other equivalent, issued to the Bidders.