Alloy 625 Grade 1 UNS N06625 W.NR. 2.4856 pipes sheets bars and wires

August 23, 2025

Stock Best Price For API 5L GR.B / ASTM A53 GR.B ERW pipe

September 4, 2025Alloy 20 / UNS N08020 / W.Nr. 2.4660: Bar, Sheet, Plate, Tubing, Pipe, Fittings, Flanges

Introduction to Alloy 20

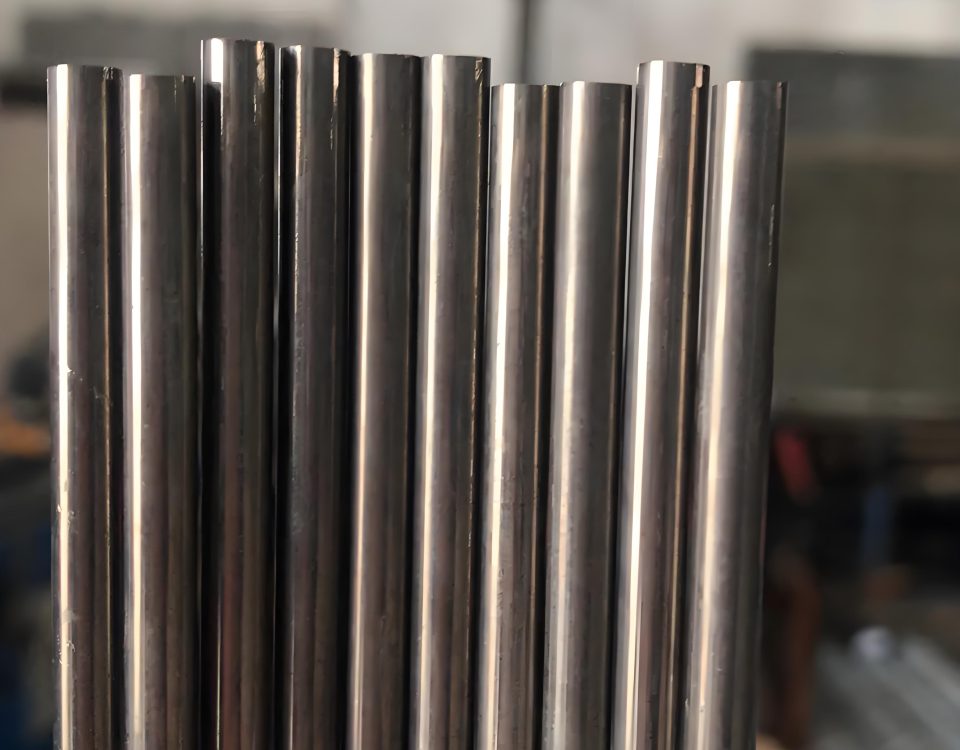

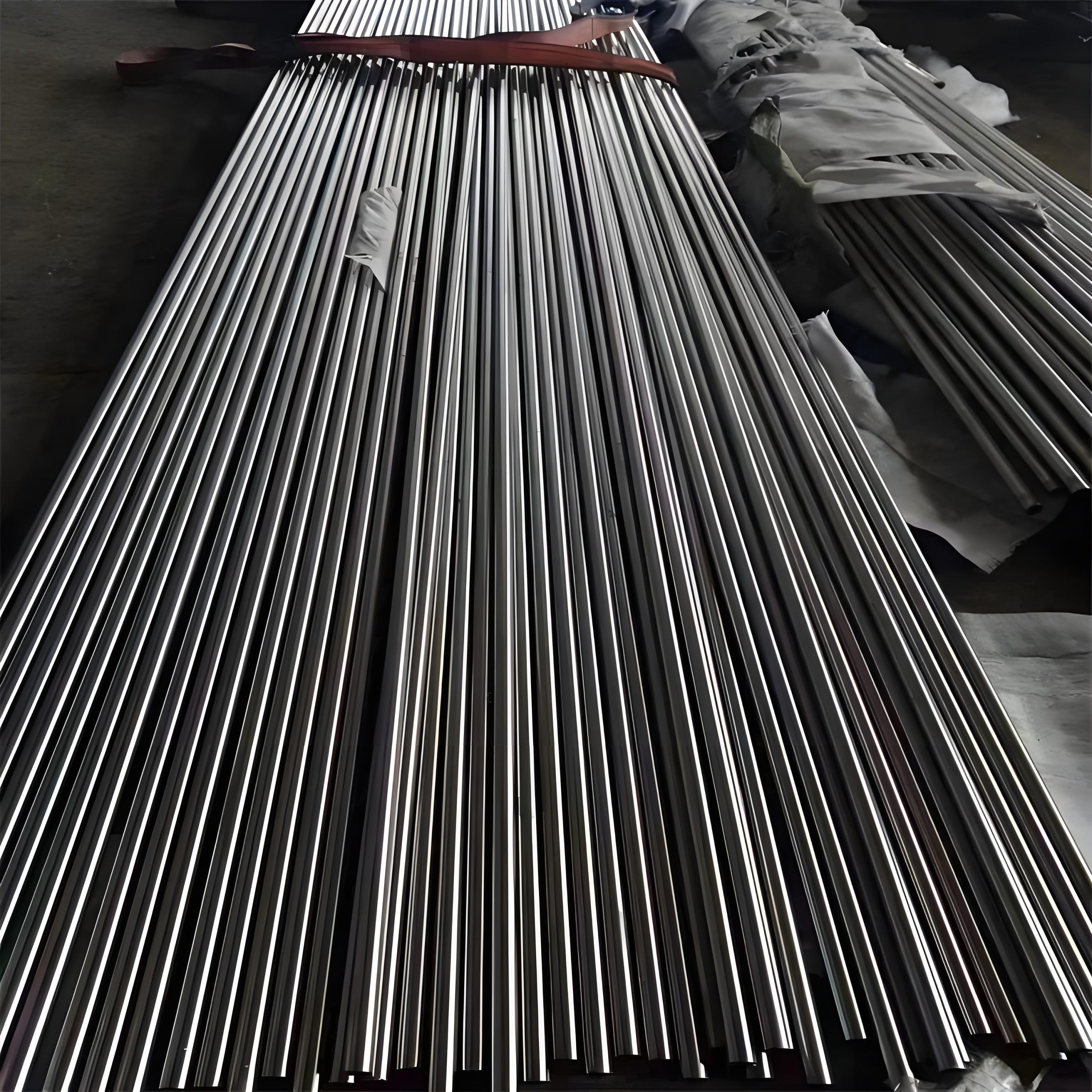

Alloy 20, also known as UNS N08020 or W.Nr. 2.4660, is a nickel-iron-chromium austenitic alloy with additions of copper and molybdenum, designed for exceptional corrosion resistance, particularly against sulfuric acid. Often referred to as Carpenter 20 or Incoloy Alloy 20, it is stabilized with niobium to resist intergranular corrosion, making it a versatile material for harsh chemical environments. Available in various forms—bar, sheet, plate, tubing, pipe, fittings, and flanges—Alloy 20 is widely used in industries such as chemical processing, petrochemical, pharmaceutical, and food processing. Its ability to resist pitting, crevice corrosion, and chloride stress-corrosion cracking (SCC) makes it ideal for applications like heat exchangers, mixing tanks, and piping systems.

The alloy’s nickel content (32-38%) places it on the boundary between stainless steel and nickel alloy, offering a cost-effective alternative to high-nickel alloys like Inconel 625 while outperforming standard stainless steels in corrosive media. Its mechanical properties and fabricability allow it to be formed into complex components, such as flanges and fittings, with excellent weldability. This article provides a detailed analysis of Alloy 20’s chemical composition, mechanical properties, corrosion resistance, manufacturing processes, applications, and dimensional tolerances across its various forms, with comparisons to Inconel 625, Incoloy 901, ASTM A671 CC60, and API 5L PSL2 BNS. Tables summarize key parameters for engineering reference, ensuring a comprehensive understanding of this superalloy’s capabilities.

Chemical Composition and Material Analysis

Alloy 20’s chemical composition is tailored for corrosion resistance and stability. It contains nickel (32.0-38.0%), chromium (19.0-21.0%), molybdenum (2.0-3.0%), copper (3.0-4.0%), iron (balance, ~29.85% min), carbon (≤0.07%), manganese (≤2.0%), silicon (≤1.0%), phosphorus (≤0.045%), sulfur (≤0.035%), and niobium plus tantalum (8xC to 1.0%). The high nickel content enhances resistance to reducing acids, while chromium provides oxidation resistance through a passive oxide layer. Molybdenum and copper improve pitting and crevice corrosion resistance, particularly in sulfuric acid environments. Niobium stabilizes the alloy against sensitization, preventing intergranular corrosion during welding.

Compared to Inconel 625 (58% min nickel, 8-10% molybdenum), Alloy 20 has lower nickel and molybdenum but higher copper, making it more resistant to sulfuric acid but less suited for extreme high-temperature corrosion. Incoloy 901 (40-45% nickel, 11-14% chromium) lacks copper, reducing its effectiveness in acid environments. ASTM A671 CC60 (0.04-0.27% carbon, 0.85-1.20% manganese) and API 5L PSL2 BNS (≤0.12% carbon, ≤1.20% manganese) are carbon steels with minimal alloying, relying on coatings for corrosion protection. Alloy 20’s austenitic structure ensures ductility and toughness, and its low carbon content minimizes carbide precipitation, making it suitable for welded components like pipes and fittings in chemical plants. The composition balances cost and performance, offering superior corrosion resistance for specific acid-heavy applications compared to standard stainless steels.

Mechanical Properties

Alloy 20 exhibits robust mechanical properties, suitable for demanding industrial applications. In the annealed condition, it has a minimum tensile strength of 551 MPa (80 ksi), yield strength of 241 MPa (35 ksi), and elongation of 30%, with a reduction of area of 50% for bars. Hardness is typically 160-200 Brinell. These properties are consistent across forms like bars, sheets, plates, tubing, pipes, fittings, and flanges, as specified in ASTM B473 (bars), B463 (sheets/plates), and B366 (fittings). The alloy retains strength and ductility at elevated temperatures up to 1000°F (538°C), per ASME limitations, making it suitable for heat exchangers and process piping.

Compared to Inconel 625 (tensile 827 MPa, yield 414 MPa), Alloy 20 has lower strength but better fabricability in acid environments. Incoloy 901 (tensile ~1150 MPa) offers higher strength but is prone to corrosion in sulfuric acid. ASTM A671 CC60 (tensile 415-550 MPa, yield 220 MPa) and API 5L PSL2 BNS (tensile 415-760 MPa, yield 245 MPa) are weaker and designed for different applications (low-temperature and sour service pipelines, respectively). Alloy 20 undergoes tensile, impact, and hardness testing to ensure reliability. Its mechanical properties support its use in structural components like flanges and fittings, where moderate strength and high corrosion resistance are required, ensuring durability in chemical and marine environments.

Corrosion Resistance Characteristics

Alloy 20 is engineered for exceptional corrosion resistance, particularly in sulfuric acid environments, with good performance in phosphoric, nitric, and chloride-containing media. Its pitting resistance equivalent number (PREN) is approximately 34, indicating strong resistance to pitting and crevice corrosion. The alloy is virtually immune to chloride stress-corrosion cracking, making it suitable for marine and chemical processing applications. Copper enhances resistance to sulfuric acid, while molybdenum protects against pitting in chlorides. Niobium stabilization prevents intergranular corrosion in welded components like pipes and fittings. Corrosion rates in hot sulfuric acid are low (0.1-0.5 mm/year), though caution is needed in high-chloride environments where pitting can increase.

Compared to Inconel 625 (PREN ~52), Alloy 20 is less resistant to extreme corrosives but excels in sulfuric acid. Incoloy 901, with lower molybdenum, is less effective against pitting. ASTM A671 CC60 and API 5L PSL2 BNS, both carbon steels, require coatings like epoxy or polyethylene to resist corrosion, unlike Alloy 20’s inherent resistance. The alloy’s performance in pickling tanks, reactor vessels, and food processing equipment highlights its reliability. External coatings can further enhance longevity in aggressive environments, but its intrinsic properties make it a preferred choice for applications like flue-gas desulfurization and pharmaceutical processing, where corrosion resistance is critical.

Manufacturing and Processing

Alloy 20 is manufactured using vacuum induction melting or electric arc furnaces, followed by hot or cold working to produce bars, sheets, plates, tubing, pipes, fittings, and flanges. Hot working is performed at 2100-2250°F (1149-1232°C) to avoid work-hardening, with annealing at 1700-1850°F (927-1010°C) to restore ductility. Cold working enhances strength for bars and sheets, followed by stress relieving or solution annealing to improve corrosion resistance. Welding uses techniques like GTAW, GMAW, or SMAW with matching filler metals (e.g., ER320LR), ensuring minimal carbide precipitation. Machining requires rigid setups and carbide tools due to the alloy’s high shear strength.

Compared to Inconel 625, which requires similar but more precise heat treatments, Alloy 20 is easier to fabricate due to lower nickel content. Incoloy 901’s precipitation hardening complicates processing, while ASTM A671 CC60 and API 5L PSL2 BNS use simpler carbon steel welding (e.g., EFW, LSAW). Alloy 20’s forms are produced to ASTM standards: B473 (bars), B463 (sheets/plates), B729/B464 (seamless/welded pipes), B468 (tubes), and B366 (fittings). Non-destructive testing (ultrasonic, radiographic) ensures quality, particularly for welded pipes and fittings. The alloy’s fabricability supports complex components like elbows, tees, and flanges, making it versatile for chemical and petrochemical systems where precise forming and welding are essential.

Applications

Alloy 20 is widely used across industries due to its corrosion resistance and versatility in various forms. Bars are used for fasteners, valve stems, and pump shafts in chemical processing. Sheets and plates serve as cladding for storage tanks and reactor vessels in pharmaceutical and food industries. Tubing and pipes are critical in heat exchangers, process piping, and pickling equipment, handling sulfuric and phosphoric acids. Fittings (e.g., elbows, tees, reducers) and flanges connect piping systems in petrochemical and marine applications. Specific uses include bubble caps, mixing tanks, and equipment for flue-gas desulfurization, where resistance to sulfur compounds is vital.

Compared to Inconel 625, used in aerospace and severe marine environments, Alloy 20 targets acid-heavy applications at lower cost. Incoloy 901 is limited to high-temperature aerospace, lacking acid resistance. ASTM A671 CC60 is for low-temperature pipelines, and API 5L PSL2 BNS for sour gas lines, neither offering Alloy 20’s corrosion resistance. The alloy’s use in synthetic rubber manufacturing, dye production, and pharmaceutical equipment highlights its adaptability. Its ability to be fabricated into complex fittings and flanges ensures reliable performance in harsh environments, reducing maintenance costs and enhancing system longevity in chemical and food processing plants.

Dimensional Tolerances

Dimensional tolerances for Alloy 20 products are specified by ASTM standards to ensure precision. Bars (ASTM B473) range from 5 mm to 500 mm in diameter, with tolerances of ±0.1 mm for small diameters and ±1% for larger ones. Sheets and plates (ASTM B463) have thicknesses of 0.5-10 mm (cold-rolled) and 3-200 mm (hot-rolled), with tolerances of ±0.1 mm for thin sheets and ±1.5 mm for thick plates. Seamless pipes/tubes (B729) and welded pipes/tubes (B464/B468) range from 0.5-8 inches in diameter, with OD tolerances of ±0.5% and wall thickness ±10%. Fittings (B366) and flanges follow ASME B16.9/B16.5, with tolerances of ±1 mm for small fittings and ±3 mm for large flanges.

Compared to Inconel 625 (ASTM B446: ±0.25 mm for bars), Alloy 20 has similar tolerances but is easier to machine. Incoloy 901 requires tighter controls for aerospace precision. ASTM A671 CC60 (±0.5% OD) and API 5L PSL2 BNS (±0.75% OD) have looser tolerances due to larger pipeline sizes. Alloy 20’s tolerances ensure compatibility in complex systems, with end finishes (e.g., beveled, threaded) meeting ASME standards for welding and assembly. These specifications guarantee reliable installation in applications like chemical piping and pharmaceutical equipment, minimizing operational issues.

Technical Specifications and Parameter Table

The following table summarizes key parameters for Alloy 20 across its various forms, providing a reference for engineers.

| Parameter | Specification |

|---|---|

| Alloy Designation | Alloy 20 (UNS N08020, W.Nr. 2.4660) |

| Chemical Composition | Ni: 32.0-38.0%, Cr: 19.0-21.0%, Mo: 2.0-3.0%, Cu: 3.0-4.0%, Fe: Bal, C: ≤0.07%, Mn: ≤2.0%, Si: ≤1.0%, P: ≤0.045%, S: ≤0.035%, Nb+Ta: 8xC-1.0% |

| Density | 8.08 g/cm³ (0.292 lb/in³) |

| Melting Point | 1425°C (2600°F) |

| Tensile Strength (Annealed) | 551 MPa (80 ksi) min |

| Yield Strength (Annealed) | 241 MPa (35 ksi) min |

| Elongation | 30% min |

| Hardness | 160-200 Brinell |

| Corrosion Resistance | Excellent in sulfuric acid, chlorides; PREN ~34 |

| Temperature Limit | 1000°F (538°C) per ASME |

| Forms | Bar, Sheet, Plate, Tubing, Pipe, Fittings, Flanges |

| Standards | ASTM B473 (Bar), B463 (Sheet/Plate), B729/B464 (Pipe), B468 (Tube), B366 (Fittings), ASME SB463/SB464/SB366 |

| Weldability | Excellent, filler ER320LR |

| Applications | Chemical processing, pharmaceutical, food processing, petrochemical, marine |

This table provides a concise overview of Alloy 20’s specifications, aiding in design and procurement decisions.

Comparison with Other Alloys

Alloy 20 is compared to Inconel 625, Incoloy 901, ASTM A671 CC60, and API 5L PSL2 BNS for its performance. Inconel 625 (tensile 827 MPa, PREN ~52) offers superior corrosion resistance in high-temperature and chloride environments but is costlier. Incoloy 901 (tensile ~1150 MPa) excels in high-temperature strength but lacks acid resistance. ASTM A671 CC60 (tensile 415-550 MPa) is for low-temperature pipelines, requiring coatings for corrosion. API 5L PSL2 BNS (tensile 415-760 MPa) is optimized for sour service but not for general acid resistance. Alloy 20’s balance of corrosion resistance, strength, and cost makes it ideal for sulfuric acid-heavy applications, outperforming carbon steels and competing with high-nickel alloys in specific environments.

Challenges and Limitations

Alloy 20 faces challenges in high-chloride environments, where pitting corrosion can occur, requiring careful design and monitoring. Its temperature limit of 1000°F (538°C) restricts use in high-heat applications compared to Inconel 625 (up to 1800°F). Machining is difficult due to work-hardening, necessitating sharp tools and low cutting speeds. Compared to carbon steels like ASTM A671 CC60 or API 5L BNS, Alloy 20 is more expensive, limiting its use to applications where corrosion resistance is critical. Welding requires clean surfaces to avoid contamination, and high costs compared to stainless steels can be a barrier. These challenges are mitigated through proper fabrication techniques, coatings, and application-specific design, ensuring reliability in chemical and marine systems.

Future Trends and Innovations

The future of Alloy 20 involves advancements in manufacturing and applications. Additive manufacturing is being explored for custom fittings and flanges, reducing waste and enabling complex designs. Improved welding techniques, like laser welding, enhance joint integrity for pipes and tubing. Nanotechnology-based coatings are improving corrosion resistance in high-chloride environments, extending service life. The alloy’s use in sustainable industries, such as green chemical processing and food production, is growing due to its non-toxicity and durability. Compared to Inconel 625’s focus on aerospace, Alloy 20 targets chemical and pharmaceutical innovations. ASTM A671 and API 5L materials are seeing coating advancements, but Alloy 20’s inherent resistance positions it for high-value applications. Digital monitoring for corrosion and stress will further enhance its reliability, ensuring continued relevance in corrosive environments.

Conclusion

Alloy 20 (UNS N08020, W.Nr. 2.4660) is a versatile nickel-iron-chromium alloy with excellent corrosion resistance, particularly in sulfuric acid environments. Available in bars, sheets, plates, tubing, pipes, fittings, and flanges, it serves chemical, pharmaceutical, and food processing industries. Its mechanical properties (551 MPa tensile, 241 MPa yield) and fabricability support complex components, while its corrosion resistance (PREN ~34) outperforms carbon steels like ASTM A671 CC60 and API 5L PSL2 BNS. Compared to Inconel 625 and Incoloy 901, it offers cost-effective acid resistance. The provided table summarizes key data, aiding engineers. Future innovations in manufacturing and coatings will enhance its utility, ensuring Alloy 20 remains a critical material for harsh environments.

[](https://www.textronsteelalloys.com/alloy-20-round-bar-uns-n08020-2-4660/)[](https://megamex.com/alloy-20/)