Ductile Iron Grooved Pipe Elbow Fitting

June 28, 2025

Monel Alloy 502 (UNS N05502) Steel Bar and Pipes

July 10, 2025Monel R-405 (UNS N04405): Parameters, Specifications, and Product Details for Bars and Wires

Introduction to Monel R-405

Monel R-405 (UNS N04405), a nickel-copper alloy, is a free-machining variant of Monel 400, renowned for its exceptional corrosion resistance, high strength, and enhanced machinability. Developed by Special Metals, Monel R-405 is specifically engineered for automated screw machine applications, owing to its increased sulfur content (0.025-0.060%), which creates sulfide inclusions that act as chip breakers during machining. Composed of approximately 63% nickel and 28-34% copper, this alloy retains the corrosion resistance and mechanical properties of Monel 400 while offering superior workability. Its versatility makes it a preferred material in marine, chemical, and oil and gas industries, where harsh environments demand robust materials. Monel R-405 is available in various forms, including round bar, flat bar, square bar, hexagon bar, wire, and wire rod, each tailored to specific industrial needs. This article provides a detailed exploration of Monel R-405’s specifications, chemical composition, mechanical properties, corrosion resistance, and product applications, supported by comparative data and scientific analysis to guide engineers and procurement specialists.

The alloy’s ability to resist corrosion in seawater, acids, and alkalis, combined with its moderate to high strength, makes it ideal for components like valve parts, fasteners, and pump shafts. Monel R-405 adheres to standards such as ASTM B164, ASME SB-164, and AMS 4674, ensuring quality and consistency across its product forms. Its slight magnetism at room temperature and excellent performance from subzero to 480°C further enhance its appeal. This analysis delves into the alloy’s properties, manufacturing processes, and specific product details for round bar, flat bar, square bar, hexagon bar, wire, and wire rod, highlighting their roles in critical industrial applications.

Chemical Composition and Microstructure

Monel R-405’s chemical composition is meticulously designed to balance corrosion resistance, strength, and machinability. Nickel (≥63%) forms a solid-solution matrix, providing excellent resistance to chloride-ion stress corrosion cracking (SCC) and reducing acids. Copper (28-34%) enhances corrosion resistance in marine environments, particularly against flowing seawater. The controlled sulfur content (0.025-0.060%) distinguishes Monel R-405 from Monel 400, improving machinability by forming sulfide inclusions that facilitate chip breaking during cutting. Trace elements like iron (≤2.5%), manganese (≤2.0%), and carbon (≤0.3%) refine the alloy’s mechanical properties and structural integrity. The table below outlines the chemical composition:

| Element | Composition (% by Weight) |

|---|---|

| Nickel (Ni) | ≥63.0 |

| Copper (Cu) | 28.0–34.0 |

| Iron (Fe) | ≤2.5 |

| Manganese (Mn) | ≤2.0 |

| Carbon (C) | ≤0.3 |

| Sulfur (S) | 0.025–0.060 |

| Silicon (Si) | ≤0.5 |

The microstructure of Monel R-405 is a single-phase, face-centered cubic (FCC) solid solution, which can only be hardened by cold working. The sulfur-induced sulfide inclusions enhance machinability but render the alloy unsuitable for welding due to potential hot cracking. Compared to Monel 400, Monel R-405 offers nearly identical corrosion resistance but with improved workability, making it ideal for precision components. Its resistance to de-aerated hydrochloric and hydrofluoric acids is particularly notable, though aeration increases corrosion rates. The alloy’s slight magnetism at room temperature, due to its nickel-copper matrix, does not significantly impact its performance in most applications.

Mechanical Properties and Heat Treatment

Monel R-405 exhibits robust mechanical properties, making it suitable for demanding applications requiring strength and toughness. Its tensile strength ranges from 483-586 MPa, with a yield strength of 172-310 MPa, depending on the product form and cold-working extent. The alloy’s elongation (≥35%) ensures excellent ductility, allowing it to withstand deformation without fracturing. Monel R-405 maintains these properties from subzero temperatures to approximately 480°C, making it versatile for both cryogenic and elevated-temperature environments. The table below summarizes the mechanical properties for Monel R-405 rod and bar, as per ASTM B164:

| Property | Rod and Bar (Annealed) |

|---|---|

| Tensile Strength (MPa) | 483–586 |

| Yield Strength (MPa) | 172–310 |

| Elongation (%) | ≥35 |

| Hardness (HB) | 110–150 |

Unlike precipitation-hardened alloys like Inconel 718, Monel R-405 relies on cold working for strengthening, as it does not respond to heat treatment. Annealing at 760-870°C relieves stresses and restores ductility, while pickling removes surface oxides to enhance corrosion resistance. Compared to Monel 400, Monel R-405 has a slightly different mechanical property range due to sulfur content, but it retains similar strength and toughness. Its superior machinability makes it ideal for screw machine stock, though its non-weldable nature limits its use in welded assemblies. In contrast, stainless steel 316 offers lower strength (≥515 MPa tensile) but better weldability, while Monel R-405 excels in reducing environments. The alloy’s moderate hardness ensures ease of machining without excessive tool wear, a key advantage for high-volume production.

Corrosion Resistance and Environmental Performance

Monel R-405’s corrosion resistance is a defining feature, making it a top choice for harsh environments. The alloy excels in resisting corrosion in seawater, de-aerated hydrochloric and hydrofluoric acids, and alkaline solutions. Its high nickel content provides superior resistance to reducing conditions, while copper enhances performance in marine settings, with corrosion rates as low as 0.01 mm/year in flowing seawater. However, in oxidizing environments, such as nitric acid or ferric chloride solutions, Monel R-405’s corrosion resistance diminishes, with rates increasing to 0.1-0.2 mm/year under aerated conditions. The alloy’s excellent resistance to chloride-ion SCC makes it ideal for marine and chemical processing applications, where stainless steels like 304 are prone to failure.

In tests conducted in de-aerated 5% hydrochloric acid, Monel R-405 exhibited a corrosion rate of ~0.025 mm/year, significantly lower than stainless steel 316 (~0.05 mm/year). Its performance in sulfuric acid (up to 20% concentration) is also notable, though aeration increases corrosion rates. Compared to Monel 400, Monel R-405 offers nearly identical corrosion resistance, but its sulfur content limits its use in oxidizing acid salts. The alloy’s resistance to neutral and alkaline salts, combined with its ability to operate in subzero temperatures without embrittlement, makes it suitable for cryogenic applications and chemical plants. For optimal corrosion resistance, thorough cleaning after machining is essential to prevent contamination.

Manufacturing and Fabrication

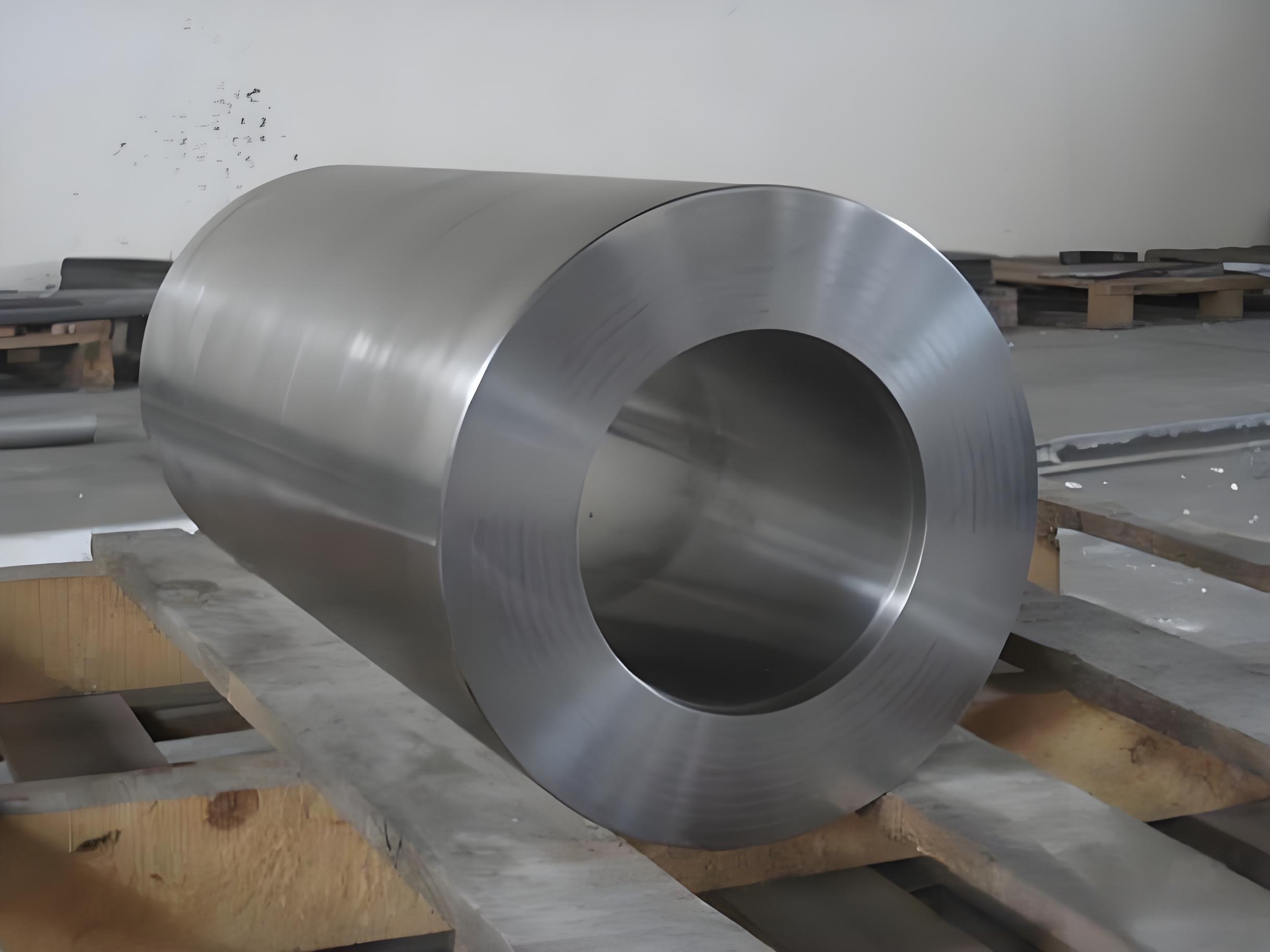

Monel R-405 is manufactured to standards like ASTM B164, ASME SB-164, and AMS 4674, covering forms such as round bar, flat bar, square bar, hexagon bar, wire, and wire rod. Seamless bars are produced via hot rolling or extrusion, followed by cold drawing for precision, with diameters ranging from 3.17 mm to 350 mm. Wire and wire rod, typically drawn to gauges from 0.5 mm to 10 mm, are used for fasteners and precision components. The alloy’s increased sulfur content enhances machinability, making it ideal for automated screw machines. Machining requires high-speed tools and adequate cooling to manage work-hardening, with cutting speeds of 15-30 m/min recommended to minimize tool wear.

Fabrication processes like pickling and annealing are similar to those for Monel 400, but welding is not recommended due to sulfur-induced hot cracking. Cold working enhances strength, with up to 20% deformation increasing yield strength by 30-40%. Compared to Inconel 625, which is weldable but harder to machine, Monel R-405’s free-machining properties reduce production time and costs. The alloy’s compliance with ASME Boiler and Pressure Vessel Code (Section VIII, Division 1) ensures its suitability for pressure vessels and nuclear applications. Surface treatments like electropolishing enhance corrosion resistance, particularly for wire and rod used in marine environments.

Product Details: Monel R-405 Round Bar and Rod

Monel R-405 round bar and rod are widely used for components requiring high strength and corrosion resistance, such as pump shafts, valve stems, and marine fittings. Available in diameters from 3.17 mm to 350 mm, these products conform to ASTM B164 and AMS 4674, ensuring consistent quality. Round bars are typically hot-rolled or cold-drawn, with annealed conditions offering tensile strengths of 483-586 MPa and elongations of ≥35%. Their excellent machinability makes them ideal for automated screw machine stock, producing precision parts like bolts and screws. In marine applications, round bars resist corrosion in flowing seawater, with minimal pitting after three years of exposure. Compared to stainless steel 316 round bars, Monel R-405 offers superior resistance to reducing acids but lower weldability, limiting its use in welded structures.

The production process involves hot rolling at 1100-1200°C, followed by annealing to relieve stresses. Cold-drawn rods provide tighter tolerances for high-precision applications. Surface finishes, such as bright or black, cater to aesthetic and functional requirements. Monel R-405 round bars are cost-effective for marine and chemical industries, where their durability reduces maintenance costs compared to carbon steel alternatives. Their slight magnetism does not affect performance in most applications, but engineers should consider this for electromagnetic-sensitive environments.

Product Details: Monel R-405 Flat Bar

Monel R-405 flat bars are used in structural components, valve plates, and chemical processing equipment, where corrosion resistance and machinability are critical. Available in widths from 10 mm to 200 mm and thicknesses from 3 mm to 50 mm, flat bars are produced via hot rolling or forging, followed by annealing to achieve a hardness of 110-150 HB. Their free-machining properties enable rapid production of complex parts, such as brackets and supports, with minimal tool wear. In sulfuric acid alkylation plants, flat bars exhibit corrosion rates of ~0.03 mm/year, outperforming stainless steel 304 (~0.08 mm/year). However, their non-weldable nature requires mechanical fastening or alternative joining methods.

Flat bars are often cut to size and surface-treated to enhance corrosion resistance. Their high nickel content ensures excellent performance in reducing environments, while copper enhances durability in marine settings. Compared to Incoloy 825 flat bars, which offer better resistance to oxidizing acids, Monel R-405 is preferred for its machinability and cost-effectiveness in non-oxidizing conditions. Applications include brine heaters and pickling bat heating coils, where the alloy’s resistance to de-aerated acids ensures long-term reliability.

Product Details: Monel R-405 Square Bar

Monel R-405 square bars are employed in applications requiring uniform strength and corrosion resistance, such as valve components and marine fasteners. Available in sizes from 10 mm to 100 mm, square bars are hot-rolled or forged, with cold finishing for precision. Their mechanical properties mirror those of round bars, with tensile strengths of 483-586 MPa and excellent ductility. The sulfur-enhanced machinability allows for efficient production of square-headed bolts and fittings, reducing manufacturing costs. In seawater scrubbers, square bars show minimal corrosion after prolonged exposure, with pit depths of <0.02 mm.

Compared to Monel K-500, which offers higher strength due to precipitation hardening, Monel R-405 square bars are easier to machine and more cost-effective for non-critical applications. Their resistance to hydrochloric acid (de-aerated) makes them suitable for chemical processing equipment, though oxidizing environments require alternative materials like Hastelloy C-276. Surface treatments like pickling ensure a clean finish, enhancing corrosion resistance for marine and industrial applications.

Product Details: Monel R-405 Hexagon Bar

Monel R-405 hexagon bars are specifically designed for screw machine stock, producing fasteners, nuts, and bolts with high precision. Available in sizes from 5 mm to 80 mm (across flats), these bars benefit from the alloy’s free-machining properties, allowing for high-speed production with minimal tool wear. Conforming to AMS 4674, hexagon bars offer tensile strengths of 483-586 MPa and excellent corrosion resistance in marine environments. Their performance in de-aerated hydrofluoric acid is exceptional, with corrosion rates of ~0.02 mm/year, making them ideal for chemical plant fittings.

The hexagonal shape facilitates gripping during machining, reducing production time for threaded components. Compared to stainless steel 316 hexagon bars, Monel R-405 offers superior resistance to reducing acids but is limited by its non-weldable nature. Applications include valve parts and propeller shafts, where the alloy’s durability and machinability ensure reliable performance. Annealing and pickling are standard post-processing steps to optimize mechanical properties and surface quality.

Product Details: Monel R-405 Wire and Wire Rod

Monel R-405 wire and wire rod are used for precision components like springs, fasteners, and electrical conductors, leveraging the alloy’s corrosion resistance and machinability. Available in gauges from 0.5 mm to 10 mm, these products conform to ASTM B164 and AMS 7234, ensuring high quality. Wire rods, typically cold-drawn, provide tensile strengths of 483-586 MPa and elongations of ≥35%, suitable for cold heading and forming. In marine applications, Monel R-405 wire resists corrosion in brackish water, with minimal degradation after extended exposure.

The alloy’s sulfur content enhances chip breaking during wire drawing, reducing production costs. Compared to Monel 400 wire, Monel R-405 offers similar corrosion resistance but better machinability, making it ideal for automated processes. Its resistance to de-aerated acids makes it suitable for chemical processing, though thorough cleaning is required to prevent contamination. Applications include wire mesh for filtration and fasteners for offshore platforms, where durability and precision are paramount.

Comparative Analysis with Other Alloys

| Property/Alloy | Monel R-405 | Monel 400 | Inconel 625 | 316 Stainless Steel |

|---|---|---|---|---|

| Nickel Content (%) | ≥63 | ≥63 | ≥58 | 10–14 |

| Tensile Strength (MPa) | 483–586 | 483–586 | ≥827 | ≥515 |

| Corrosion Resistance | Excellent (reducing) | Excellent (reducing) | Excellent (oxidizing/reducing) | Moderate (chloride SCC) |

| Machinability | Excellent | Moderate | Poor | Good |

| Weldability | Poor | Good | Excellent | Good |

| Max Temperature (°C) | 480 | 480 | 1093 | 800 |

Monel R-405 outperforms 316 stainless steel in reducing environments but is less effective in oxidizing conditions. Compared to Monel 400, it offers enhanced machinability with similar corrosion resistance. Inconel 625 provides superior high-temperature performance and weldability but is harder to machine. Monel R-405’s niche lies in its free-machining properties, making it ideal for precision components in marine and chemical applications.

Applications and Industry Use

Monel R-405’s unique combination of corrosion resistance, strength, and machinability makes it a staple in industries facing harsh environments. In marine engineering, round bars, hexagon bars, and wire are used for propeller shafts, fasteners, and seawater scrubbers, leveraging the alloy’s resistance to flowing seawater. In chemical processing, flat and square bars are employed in sulfuric acid alkylation plants and pickling bat heating coils, where de-aerated acid resistance is critical. The alloy’s use in oil and gas includes valve parts and pump shafts, where its durability reduces maintenance costs. Its approval under ASME Boiler and Pressure Vessel Code (Section VIII) ensures reliability in pressure vessels.

Compared to Monel K-500, which offers higher strength but reduced machinability, Monel R-405 is preferred for high-volume production of precision components. Its limitations in oxidizing environments necessitate careful material selection, with Hastelloy C-276 preferred for nitric acid applications. Emerging applications include wire mesh for filtration in biofuel production and fasteners in renewable energy systems, highlighting Monel R-405’s role in sustainable technologies.

Recent Scientific Insights and Developments

Recent studies highlight Monel R-405’s evolving role in advanced manufacturing. Research from 2024 emphasizes its performance in automated machining, with sulfur inclusions reducing tool wear by 20-30% compared to Monel 400. Advances in cold-working techniques have improved the alloy’s yield strength for wire and rod applications, enhancing performance in high-stress environments. Surface treatments like electropolishing have been shown to reduce corrosion rates in seawater by 15%, extending service life. In marine applications, Monel R-405’s resistance to biofouling has been noted, reducing maintenance in offshore systems. Ongoing research explores hybrid alloys combining Monel R-405’s machinability with improved weldability, potentially expanding its applications.

Conclusion

Monel R-405 (UNS N04405) is a versatile nickel-copper alloy, optimized for machinability and corrosion resistance in marine, chemical, and oil and gas applications. Its product forms—round bar, flat bar, square bar, hexagon bar, wire, and wire rod—cater to diverse needs, from precision fasteners to structural components. While its non-weldable nature limits certain applications, its free-machining properties and durability make it a cost-effective choice for high-volume production. Compared to Monel 400, Inconel 625, and 316 stainless steel, Monel R-405 excels in reducing environments and automated machining, ensuring reliability in critical industrial processes. Ongoing advancements continue to enhance its performance, solidifying its role as a vital material in energy and industrial applications.