seamless steel tube,seamless steel pipe

November 19, 2018

API 5L / ASTM A106 / A53 Gr. B Seamless Carbon Steel Tube / Pipe

November 28, 2018What is threaded flange and what is its features?

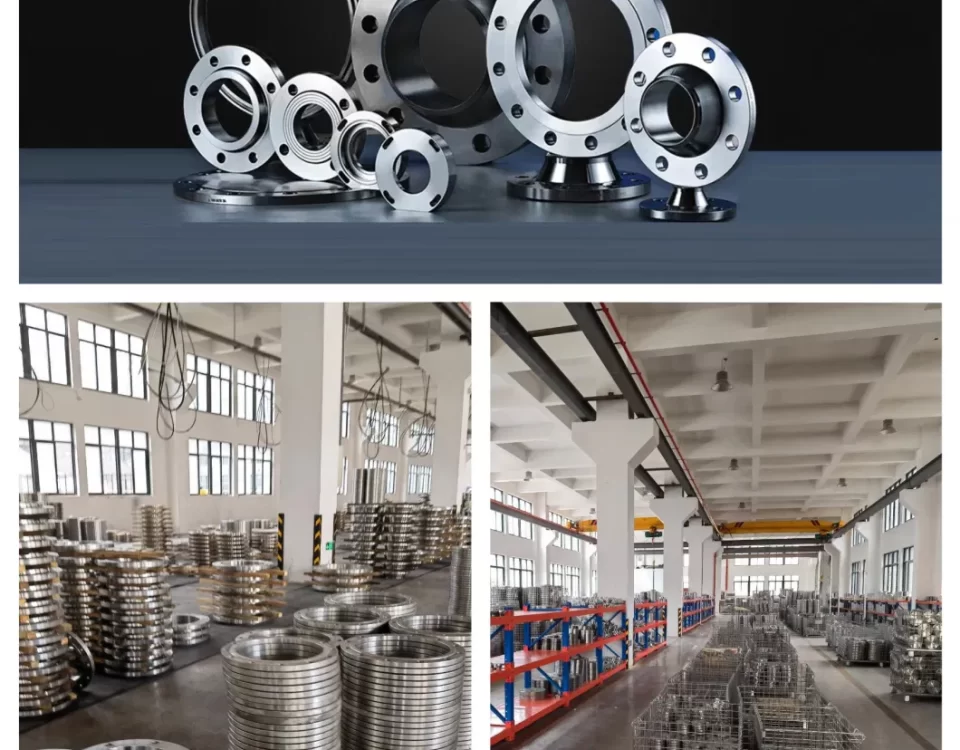

A threaded flange is a type of flange that is threaded to the pipe. Designed with a loose flange.

Threaded flanges are made by machining the inner bore of the flange into a pipe thread and connecting it with a threaded pipe. It is a non- welded flange . It welded flange or welded flange, compared with the threaded mounting flange, convenient maintenance, the line can not be welded in some field of use. Alloy steel flanges have sufficient strength, but are not easy to weld, or the welding performance is not good, you can also choose a threaded flange. However, when the pipe temperature changes sharply or the temperature is higher than 260 ° C and lower than -45 ° C, it is recommended not to use a threaded flange to avoid leakage.

Threaded flanges look very similar to Slip-On flanges but the main difference is that the threaded flange has been was bored out to match a specific pipe inside diameter. The backside of this center opening is then threaded with the relevant-sized tapered pipe thread.

The advantage of threaded flange is that no welding is required, and the additional torque generated on the barrel or pipe is small when the flange is deformed. The disadvantage is that the flange is thick and the cost is high. The threaded flange is suitable for connection to high pressure pipes.

Materials of threaded flange :

- CARBON STEEL – ASTM/ASME SA-105, A-350 LF-2, LF-3, A694, SA-516-70, A36

CHROME ALLOYS – A-182-F-1, F-5, F-6, F-7, F-9, F-11, F-12, F-22, F-51

STAINLESS STEEL – A-182 – F-304, 304L, 316, 316L, 309, 310, 317L, 321, 347,

Alloy 20

ALUMINUM – 1100, 2014, 3003, 5083, 5086, 6061, 7075

HASTALLOY – B-2, C-276, G, X

INCONEL – 600, 601, 625, 718

INCOLLOY – 800, 825

MONEL – 400

COPPER – C11000

NAVAL BRASS – (Bronze)

TITANIUM

Uses of threaded flange :

- Threaded flanges can be fitted to pipes of various sizes without welding and this is one chief benefit for which these flanges are highly demanded.

- Used in extremely high pressure applications, particularly at or near atmospheric temperature, where the necessary post weld heat treatment is not possible.

- They are ideal for small diameter piping applications.

- These threaded flanges are normally designed for non-cyclic applications.

- The flanges are suitable to be used in applications where welding is hazardous.

- They can be used in highly explosive areas.