L235 EN10224 ERW welded steel pipe

September 7, 2015

boiler steel pipe

June 26, 2016ASTM A53 ERW steel pipes OD 210mm

ASTM A53 steel pipes is highly used to convey fluids at low / medium pressures such as oil, gas, steam, water, air and also for mechanical applications.

Advantage of ERW pipe

ERW pipe, among the largest advantages is that only television billet ends are heated throughout the manufacturing procedure, for that reason the rest of the entire ERW pipe continues to be tidy and just the welding component has to be cleansed. This lowers the post-welding cleaning job, mainly enhancing the functioning performance as well as saving cost. Owing to the practically clean combined with smooth surface, ERW pipelines are easy to be uses with covering technique.

DETAILED INFORMATION OF ASTM A53 steel pipes OD 210mm ERW steel tubing

| Composition | |||||

| Material | C% | Mn% | S% | P% | Si% |

| Q195 | 0.06-0.12 | 0.25-0.50 | <0.050 | <0.045 | <0.30 |

| Q215 | 0.09-0.15 | 0.25-0.55 | <0.050 | <0.045 | <0.30 |

| Q235 | 0.12-0.20 | 0.30-0.70 | <0.045 | <0.045 | <0.30 |

| Q345 | <0.20 | 1.0-1.6 | <0.040 | <0.040 | <0.55 |

| Mechanical Property | |||||

| Material | Yield Point(Mpa) | Tensile Strength(Mpa) | Elongation(%) | ||

| Q195 | >195 | 315-430 | 32-33 | ||

| Q215 | >215 | 335-450 | 26-31 | ||

| Q235 | >235 | 375-500 | 24-26 | ||

| Q345 | >345 | 470-630 | 21-22 | ||

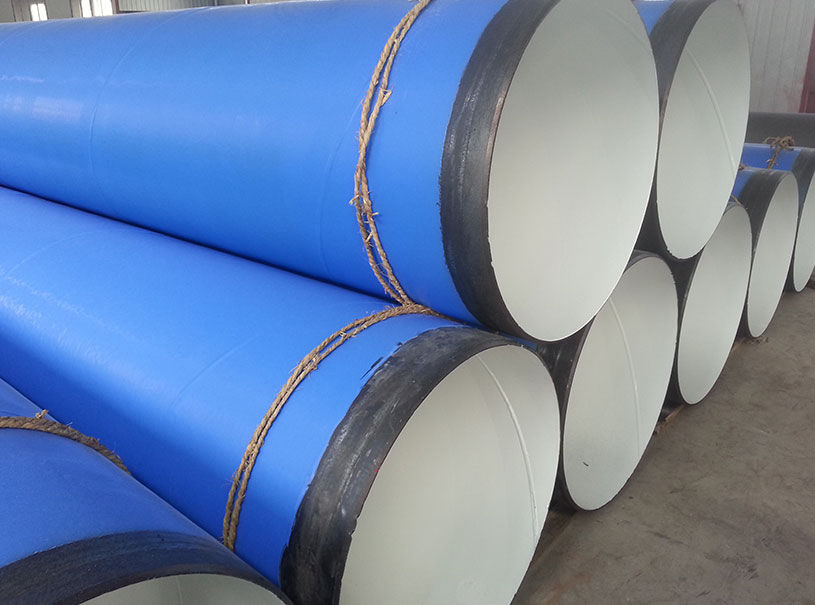

PACKAGE: Plastic caps on both ends, steel bundle, woven bag or as per customer’s requirement.

packing

2 Comments

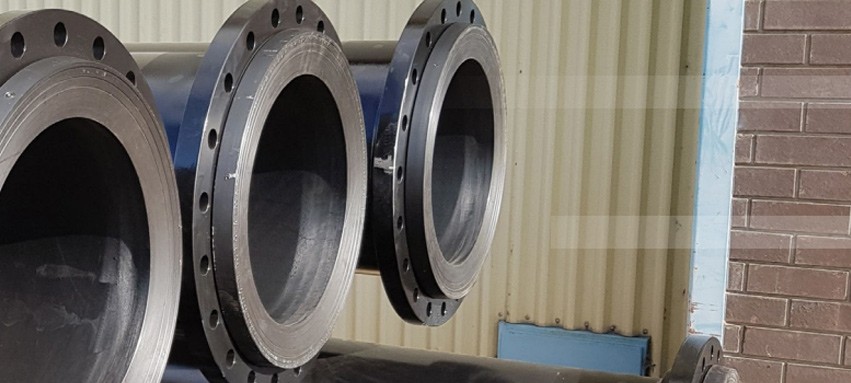

What is ASTM A53 ERW pipe?

ASTM A53 ERW steel pipe – Fire fighting pipe –

ASTM A53 ERW steel pipe is formed by rolling strip and welding the seam, with precise dimension and light weight. It can be used for water, steam and air conveyance. It is also weldable and can be used in structural applications.