DIN EN 10210 Structural Pipe, Chemical Compositon and Mechanical Properties

March 3, 2018

Size and Weight of Seamless Roll Steel Pipe Schedule,ASME B36.10M-1996

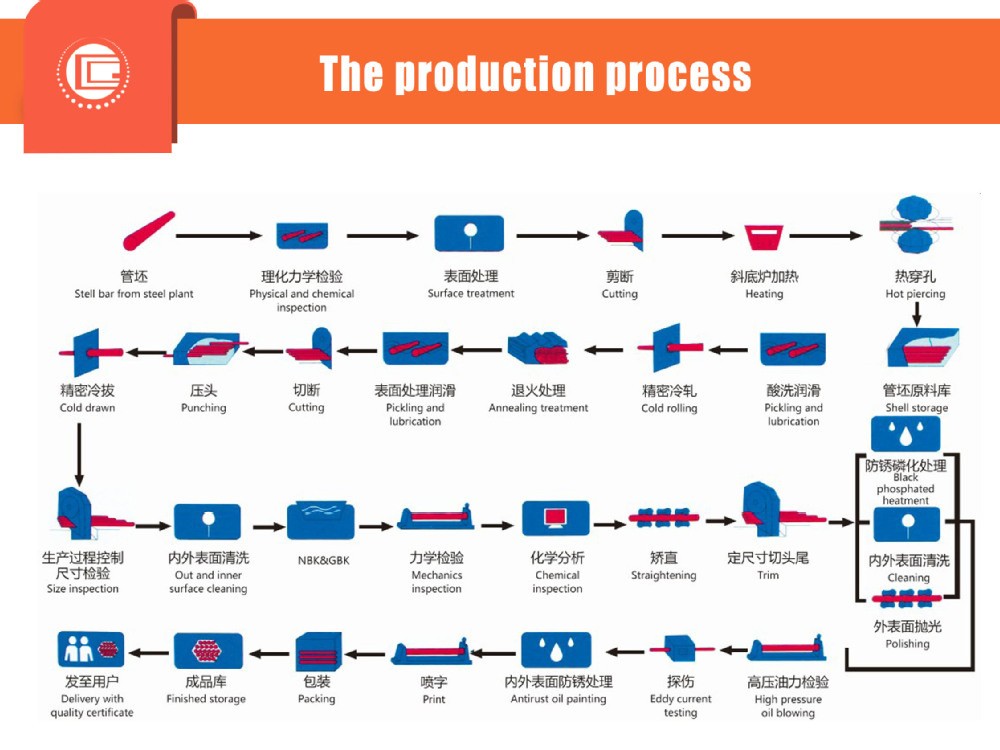

March 8, 2018Synopsis of process flow:

Using high quality raw material: ST35,ST37 ST37.4 ST52.4, cold drawn, anaerobic bright heat treatment, nondestructive examination.

Applicable standard:

IS08535-1 (steel tubes for high pressure fuel pipe in compression ignition engine), IS00404-1992 (technical requirements for steel and steel product), IS06892-1984 (tensile testing for metal).

Main feasure:

High precision, excellent brightness, after heat treatment, steel tube inside and outside wall have no oxide layer, high cleanness inner surface, flushing the inner diameter, anti-rust oil painted. Total impurity<1.5mg/g. Maximun granule 8 degree(^0.2mm). Under high pressure, no deformation after cold bending, the complicated geometrical forming and machining can be realized. Color of the tube: gray with white. The tolerance for OD and ID: ±0.05mm,high inner surface quality level for Q. Normal working pressure is 2000 kg, and test pressure reached 6000 kg without deformation. Steel tube around a circle and its outer diameter of the same diameter rod cold bending 180 °, the surface is smooth, no cracks.

Main application:

For high pressure fuel pipe in compression ignition engine, all technical requirements can reach the level of top international brand, and they are able to replace the imported tubes and reduce the cost for our customers.

SPECIFICATION LIST

|

Standard & Material |

Carbon Steel |

ASTM A519 Standard |

MT1010, MT1020, 1008, 1010, 1018, 1020, 1025, 1030, 1045, 1518 |

|

|

JIS G3445 Standard |

STKM11A STKM12A STKM12B STKM12C STKM13A STKM13B STKM13C STKM14A STKM14B STKM14C STKM15A STKM15C STKM16A STKM16C STKM17A STKM17C STKM18A STKM18B STKM18C STKM19A STKM19C STKM20A |

|||

|

JIS G3473 Standard |

STC370, STC440, STC510A, STC510, STC540, STC590A, STC590B |

|||

|

DIN 2391 Standard |

St 35, St45, St52 |

|||

|

EN 10297-1 Standard |

E235, E275, E315, E355, E470 |

|||

|

EN 10305-1 Standard |

E215, E235, E355 |

|||

|

EN 10305-4 Standard |

E215, E235, E355 |

|||

|

BS 6323-3 Standard |

HFS 3, HFS 4, HFS 5, HFS 8 |

|||

|

NF A49-311 |

TU 37-b, TU 52-b, TU 56-b, TU XC35 |

|||

|

Alloy Steel |

ASTM A519 Standard |

1345, 3140, 4130, 4135, 4140, 4150, 4320, 4340, 5120, 5130 |

||

|

JIS G3429 Standard |

STH11, 12 STH21, 122 STH31 |

|||

|

JIS G3441 Standard |

SCR420TK, SCM415TK, SCM418TK, SCM420TK, SCM430TK, SCM440TK |

|||

|

Stainless Steel |

ASTM A511 Standard |

MT304, MT304L, MT310S, MT316, MT316L, MT317, MT321, MT347, MT403, MT410, MT431 |

||

|

ISO Standard |

NACE MR-0175 |

|||

|

Size |

|

Size Range |

Tolerance |

|

|

OD |

6-325mm |

-0.035 — +0.045mm |

||

|

ID |

2-250mm |

±0.035mm |

||

|

WT |

1-32mm |

depends on sizes | ||

|

Length |

random or fixed length |

+0-3.5mm |

||

|

Straightness |

0.15:1000, 0.4:1000, 0.5:1000 1:1000 or customized |

|||

|

Surface Roughness |

Ra 0.02—0.4μm |

|||

Application

1. Automotive and mechanical pipes

2. Petroleum cracking pipes

3. High Pressure Boiler Pipe

4. Low and middle pressure fluid transportation pipeline

5. Chemical fertilizer equipment pipes

6. Heat exchanger pipes

Production equipment

1. COId Drawn Machine Cold drawing machine as the main processing

equipment of cold drawn steel tube, it is the

production of small, precise and thin wall, high

mechanical properties of pipe of the main

processing equipment.

2. High oressure washing Dlatform

High pressure washing platform is

used for out and inner surface

cleaning.

3. Anaerobic annealing lurance

Annealing is a kind of metal heatina treat-

ment process, refers to the metal slowly

heated to a certain temperature, keep en-

ough time, and then cooling at appropriate

rate. The purpose is to reduce the hardness

and improve cutting machining,eliminate

the residual stress, stable size, reduce the

deformation and crack tendency,fine grains,

adjust, eliminate defects.

4. Straightening Machine

Straightening machine is the equipment

which be used for steel pipe straightening;

After straightening steel pipe surface no

indentation, necking phenomenon, better

than the standards set by the Ministry of

construction.

5. Polishing Machine

Polishing machine is used for polishing,

derusting, dusting, descaling; make the

surface of steel pipe bright.

Testing equipment :

1. Chemical analysis instruments

Chemical analyzer is mainly used in

measurement ot element com

positon in steel fiel Accurate anal n

detection o alloy elements xnä hoy

identification.

2. Optical spectrum analyzes

Used in the detection of steel pipe’s

quality

3. Eddy current detector

Eddv current detector is used for

testina that steel pipe whether have

defecrs.

4. Mechanical tester

Used for testing steel pipe’s physical and

mechanical properties.

5. ROCkwelI hardness tester

Rockwell hardness tester used to test

the hardness of steel pipe surface.

APPLICATIONS:

THE PRODUCTION PROCESS: