ASTM A53 Gr. B black carbon steel pipe for oil and gas pipelines

June 14, 2017

API 5L PSL1 and PSL2 Carbon Seamless steel Pipeline Grade B/C

July 31, 20171. Outside Diameter: Ф219-Φ660mm

2. Wall Thickness: 6-22mm

3. Length: 3-12m

4. Steel Grade: Q345B, API X42 – X80, L245, L555,J55, N80

5. Standard: SY/T5037-2000, GB/T9711.1-97, API Spec 5L

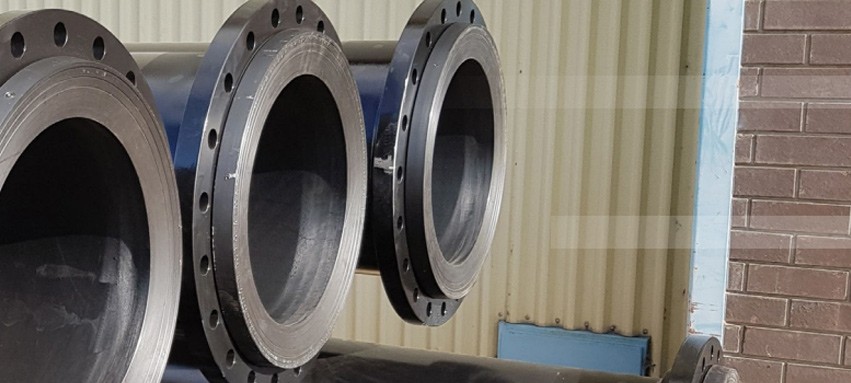

6.End:square ends (straight cut, saw cut, and torch cut). or beveled for welding, beveled,

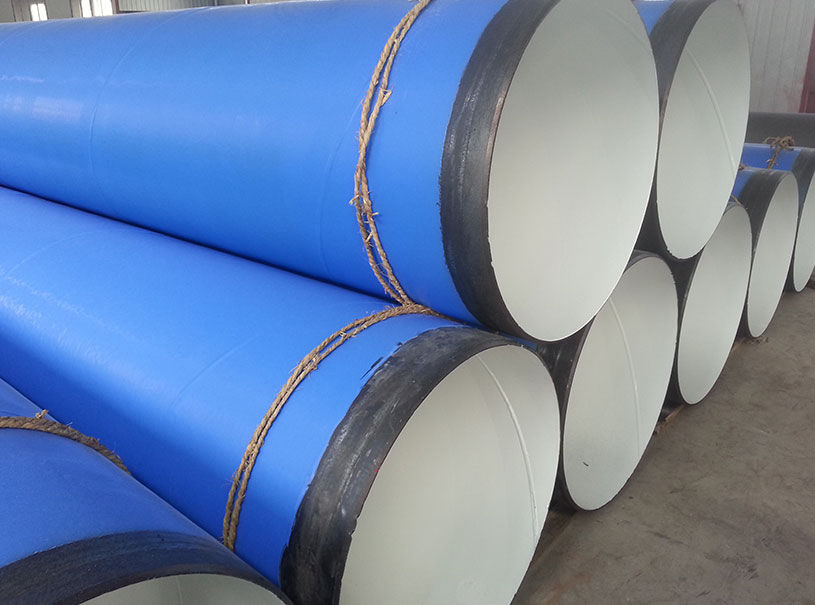

7.Surface: Lightly oiled, Hot dip galvanized, Electro galvanized, Black, Bare, Varnish coating/Anti rust oil, Protective Coatings (Coal Tar Epoxy,Fusion Bond Epoxy, 3-layers PE)

8.Test: hydro testing, ultrasonic detection, ultrasonic testing for pipe end, visual and dimension inspection, weighing and measuring, etc.

Chemical Analysis (%) of ERW Transmission Steel Pipes:

| Type of pipe | Class | Grade | C | Si | Mn | P | S | V | Nb | Ti |

| max | max | max | max | max | max | max | max | |||

| WELD | PLS1 | L245 B | 0.26 | – | 1.2 | – | 0.03 | 0.03 | – | – |

| L290 X42 | 0.26 | – | 1.3 | – | 0.03 | 0.03 | – | – | ||

| L320 X46 | 0.26 | – | 1.4 | – | 0.03 | 0.03 | – | – | ||

| L360 X52 | 0.26 | – | 1.4 | – | 0.03 | 0.03 | – | – | ||

| L390 X56 | 0.26 | – | 1.4 | – | 0.03 | 0.03 | – | – | ||

| L415 X60 | 0.26 | – | 1.4 | – | 0.03 | 0.03 | – | – | ||

| L450 X65 | 0.26 | – | 1.45 | – | 0.03 | 0.03 | – | – | ||

| L485 X70 | 0.26 | – | 1.65 | – | 0.03 | 0.03 | – | – | ||

| PLS2 | L245M BM | 0.22 | 0.45 | 1.2 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | |

| L290M X42M | 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | ||

| L320M X46M | 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | ||

| L360M X52M | 0.22 | 0.45 | 1.4 | 0.025 | 0.015 | – | – | – | ||

| L390M X56M | 0.22 | 0.45 | 1.4 | 0.025 | 0.015 | – | – | – | ||

| L415M X60M | 0.12 | 0.45 | 1.6 | 0.025 | 0.015 | – | – | – | ||

| L450M X65M | 0.12 | 0.45 | 1.6 | 0.025 | 0.015 | – | – | – | ||

| L485M X70M | 0.12 | 0.45 | 1.7 | 0.025 | 0.015 | – | – | – | ||

| L555M X80M | 0.12 | 0.45 | 1.85 | 0.025 | 0.015 | – | – |