Galvanized Steel Pipe knowledge

May 7, 2018

Steel Seamless tube DIN 1629 / 17210 For Egypt

May 15, 2018low temperature tempering (150-250 degrees)

Mechanical properties:

|

Standard |

Product Level |

Steel grade |

Yield Strength (min), Mpa |

Tensile Strength (MPa) |

|

API 5L GB/T9711.2 |

PSL 1 |

A or L210 |

210 |

335 |

|

B or L245 |

245 |

415 |

||

|

X42 or L290 |

290 |

415 |

||

|

X46 or L320 |

320 |

435 |

||

|

X52 or L360 |

360 |

460 |

||

|

X56 or L390 |

390 |

490 |

||

|

X60 or L415 |

415 |

520 |

||

|

X70 |

483 |

565 |

||

|

PSL 2 |

BR or L245R |

245~450 |

415~760 |

|

|

X42R or L290R |

290~495 |

415~760 |

||

|

BN or L245N |

245~450 |

415~760 |

||

|

X42N or L290N |

290~495 |

415~760 |

||

|

X46N or L320N |

320~525 |

435~760 |

||

|

X52N or L360N |

360~530 |

460~760 |

||

|

X56N or L390N |

390~545 |

490~760 |

||

|

X60N or L415N |

415~565 |

520~760 |

||

|

X65N or L450N |

425~566 |

525~760 |

||

|

X70 or L480 |

484~565 |

565~768 |

||

|

X80 |

552~690 |

621~827 |

Line pipe chemical element table:

|

Roduct Level |

Steel grade |

Chemical composition, % |

||||||||

|

C |

Mn |

P |

S |

Si |

V |

Nb |

Ti |

CEpcm |

||

|

PSL 1 |

B or L245 |

≤0.28 |

≤1.20 |

≤0.030 |

≤0.030 |

– |

– |

– |

– |

– |

|

X42 or L290 |

≤0.28 |

≤ 1.30 |

≤0.030 |

≤0.030 |

– |

– |

– |

– |

– |

|

|

X46 or L320 |

≤0.28 |

≤ 1.40 |

≤0.030 |

≤0.030 |

– |

– |

– |

– |

– |

|

|

X52 or L360 |

≤0.28 |

≤ 1.40 |

≤0.030 |

≤0.030 |

– |

– |

– |

– |

– |

|

|

X56 or L390 |

≤0.28 |

≤ 1.40 |

≤0.030 |

≤0.030 |

– |

– |

– |

– |

– |

|

|

X60 or L415 |

≤0.28 |

≤ 1.40 |

≤0.030 |

≤0.030 |

– |

– |

– |

– |

– |

|

|

X70 |

≤0.28 |

≤ 1.40 |

≤0.030 |

≤0.030 |

– |

– |

– |

– |

– |

|

|

PSL 2 |

BR or L245R |

≤0.24 |

≤1.20 |

≤0.025 |

≤0.015 |

≤0.40 |

c |

c |

≤0.04 |

≤0.25 |

|

X42R or L290R |

≤0.24 |

≤1.20 |

≤0.025 |

≤0.015 |

≤0.40 |

≤ 0.06 |

≤ 0.05 |

≤0.04 |

≤0.25 |

|

|

BN or L245N |

≤0.24 |

≤1.20 |

≤0.025 |

≤0.015 |

≤0.40 |

c |

c |

≤0.04 |

≤0.25 |

|

|

X42N or L290N |

≤0.24 |

≤ 1.30 |

≤0.025 |

≤0.015 |

≤0.40 |

≤ 0.06 |

≤ 0.05 |

≤0.04 |

≤0.25 |

|

|

X46N or L320N |

≤0.24 |

≤ 1.40 |

≤0.025 |

≤0.015 |

≤0.40 |

≤0.07 |

≤ 0.05 |

≤0.04 |

≤0.25 |

|

|

X52N or L360N |

≤0.24 |

≤ 1.40 |

≤0.025 |

≤0.015 |

≤0.45 |

≤0.10 |

≤ 0.05 |

≤0.04 |

≤0.25 |

|

|

X56N or L390N |

≤0.24 |

≤ 1.40 |

≤0.025 |

≤0.015 |

≤0.45 |

≤0.10 |

≤ 0.05 |

≤0.04 |

≤0.25 |

|

|

X60N or L415N |

≤0.24 |

≤ 1.40 |

≤0.025 |

≤0.015 |

≤0.45 |

≤0.10 |

≤ 0.05 |

≤0.04 |

– |

|

|

X65N or L450N |

≤0.24 |

≤ 1.40 |

≤0.025 |

≤0.015 |

≤0.45 |

≤0.10 |

≤ 0.05 |

≤0.04 |

– |

|

|

X70N |

≤0.24 |

≤ 1.40 |

≤0.025 |

≤0.015 |

≤0.45 |

≤0.10 |

≤ 0.05 |

≤0.04 |

– |

|

|

X80 |

≤0.24 |

≤ 1.40 |

≤0.025 |

≤0.015 |

≤0.45 |

≤0.10 |

≤ 0.05 |

≤0.04 |

– |

|

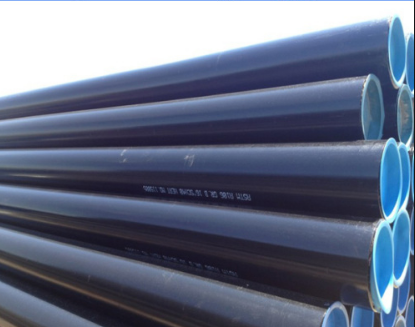

standard:

API SPEC 5L – American Petroleum Institute Standard

GB/T9711 – China National Standard

use:

Oxygen, water and oil pipelines used in the oil and gas industry

The main production steel grade:

B, X42, X52, X60, X65, X70 L245 L290 L320 L360 L390 L450 L485

Size tolerance:

|

Steel pipe type |

Steel pipe outside diameter (D) |

Steel pipe wall thickness (S) |

|

|

|

Body |

Steel tube outside diameter (mm) |

Allowable deviation (mm) |

Steel tube outside diameter (mm) |

Allowable deviation (mm) |

|

≥ 60.3 and S<20 |

±0.75% |

≤73.0 |

+15% ,-12.5% |

|

|

≥60.3 and S≥20 |

±1.00% |

>73.0 and S<20 |

+15% ,-12.5% |

|

|

|

|

>73.0 and S≥20 |

+17.5% ,-10 |

|

Mechanical properties:

|

standard |

Grade |

Tensile strength (MPa) |

Yield (MPa) |

Yield ratio |

Elongation(%) |

0 °C impact power |

Heat treatment |

|

API SPEC 5L |

L245/B |

≥415 |

245 to 440 |

≤0.80 |

twenty two |

≥40 |

Normal fire |

|

API SPEC 5L |

L290/X42 |

≥415 |

290 to 440 |

≤0.80 |

twenty one |

≥40 |

Normal fire |

|

API SPEC 5L |

L360/X52 |

≥460 |

360 to 510 |

≤0.85 |

20 |

≥40 |

Normal fire |

|

API SPEC 5L |

L415/X60 |

≥520 |

415 to 565 |

≤0.85 |

18 |

≥40 |

Normal fire |

|

API SPEC 5L |

L450/X65 |

≥535 |

450 to 570 |

≤ 0.90 |

18 |

≥40 |

Quenching + tempering |

|

API SPEC 5L |

L485/X70 |

≥570 |

485 to 605 |

≤ 0.90 |

18 |

≥40 |

Quenching + tempering |

chemical composition:

|

standard |

Grade |

chemical composition(%) |

CEV (%) |

|

|

|

|

|

|

|

|

C |

Si |

Mn |

P |

S |

V |

Nb |

Ti |

|

|

|

|

API SPEC 5L |

B |

≤0.16 |

≤0.40 |

≤1.10 |

≤0.020 |

≤0.010 |

– |

– |

– |

≤0.42 |

|

X42 |

≤0.17 |

≤0.40 |

≤1.20 |

≤0.020 |

≤0.010 |

≤ 0.05 |

≤ 0.05 |

≤0.04 |

≤0.42 |

|

|

X52 |

≤0.20 |

≤0.45 |

≤ 1.60 |

≤0.020 |

≤0.010 |

≤0.10 |

≤ 0.05 |

≤0.04 |

≤0.45 |

|

|

X60 |

≤0.21 |

≤0.45 |

≤ 1.60 |

≤0.020 |

≤0.010 |

≤0.15 |

≤ 0.05 |

≤0.04 |

protocol |

|

|

X65 |

≤0.16 |

≤0.45 |

≤ 1.60 |

≤0.020 |

≤0.010 |

≤ 0.06 |

≤ 0.05 |

≤ 0.06 |

≤0.45 |

|

|

X70 |

≤0.16 |

≤0.45 |

≤1.70 |

≤0.020 |

≤0.010 |

≤ 0.06 |

≤ 0.05 |

≤ 0.06 |

≤0.45 |

|

Note:

1.0.015%≤Altot<0.06%;N≤0.012%;Al/N≥2/1;Cu≤0.25%;Ni≤0.30%;Cr≤0.30%;Mo≤0.10%

2. V+Nb+Ti≤0.15

3. X60, X65, X70 after consultation Mo ≤ 0.35%

American Petroleum Institute Standard (API SPEC 5L) Line Pipe Spec Sheet

|

Nominal size |

Outer |

Wall thickness |

Flat |

|

|

|

|

Inch |

Mm |

Inch |

Mm |

Lb/ft |

Kg/m |

|

|

0.405 |

0.405 |

10.29 |

0.095 |

2.4 |

0.31 |

0.47 |

|

0.54 |

0.54 |

13.72 |

0.088 |

2.2 |

0.43 |

0.62 |

|

0.54 |

13.72 |

0.119 |

3.0 |

0.54 |

0.79 |

|

|

0.675 |

0.675 |

17.15 |

0.091 |

2.3 |

0.57 |

0.84 |

|

0.675 |

17.15 |

0.126 |

3.2 |

0.74 |

1.10 |

|

|

0.84 |

0.84 |

21.34 |

0.109 |

2.8 |

0.85 |

1.28 |

|

0.84 |

21.34 |

0.147 |

3.7 |

1.09 |

1.61 |

|

|

1.05 |

1.05 |

26.67 |

0.113 |

2.9 |

1.13 |

1.70 |

|

1.05 |

26.67 |

0.154 |

3.9 |

1.48 |

2.19 |

|

|

1.315 |

1.315 |

33.4 |

0.133 |

3.4 |

1.68 |

2.52 |

|

1.315 |

33.4 |

0.179 |

4.6 |

2.17 |

3.21 |

|

|

1.660 |

1.660 |

42.2 |

0.145 |

3.7 |

2.72 |

3.43 |

|

1.660 |

42.2 |

0.191 |

4.9 |

3.00 |

4.51 |

|

|

1.900 |

1.660 |

42.2 |

0.382 |

9.7 |

5.22 |

7.77 |

|

1.900 |

48.3 |

0.145 |

3.7 |

2.72 |

4.07 |

|

|

1.900 |

48.3 |

0.200 |

5.1 |

3.63 |

5.43 |

|

|

1.900 |

48.3 |

0.400 |

10.2 |

6.41 |

9.58 |

|

|

2 3/8 |

2.375 |

60.3 |

0.109 |

2.8 |

2.64 |

3.97 |

|

2.375 |

60.3 |

0.125 |

3.2 |

3.00 |

4.51 |

|

|

2.375 |

60.3 |

0.141 |

3.6 |

6.36 |

5.03 |

|