Copper Fittings inspection report

June 29, 2018

WATER PIPELINE JOINING METHODS AND PIPE INSTALLATION

July 8, 2018

|

INSPECTION REPORT Report No.: MIL 100604-01A1 Issued on: Jul 12th, 2010 Inspection Time: Jul 13th, 2010 |

P.O. No.100707 |

|

Inspection Subject: |

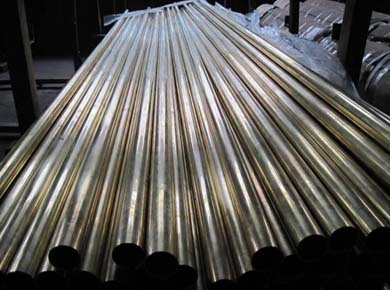

Aluminum Brass Tubes |

|

|

|

Specification: |

ASTM B111 C68700 |

Inspector : |

Lin Gaojie |

Visit Summary:

Scope of Inspection

- Visual inspection.

- Weight verification and packaging

- Physical test

- Dimension

- Documents

- Part photo

Results of inspection to MIL 100604-01A1

- Process Verification

- Visual Inspection

The tubes were good except some imperfection, and the details were as followed:

- The outside surface of tubes was bright;

- Tube ends have squared cut and deburred;

- Most of the straightness of accepted tubes can be considered to be good after measuring the tubes

Photo attachment as below

|

|

|

|

For checking |

|

|

|

|

Tube surface |

Tube ends |

- Packaging inspection and weight verification

- The tubes were bundled and packaged by poly bags;

- There are simple labels on the end of the package, and the manufacturer labels will be removed before loading;

- The weight is in the following

|

Item No. |

Size / mm |

weight / Kg |

Quantity / pcs |

Kg/pc |

|

1 |

10*0.5*4000 |

34 |

70 |

0.486 |

|

2 |

16*1*4000 |

332 |

210 |

1.581 |

|

3 |

30*2*4000 |

598 |

100 |

0.598 |

Photo attachment as below

|

|

|

Packaging |

Weighing |

- Physical test verification

The tension test of 7 test pieces and hardness test of 4 test pieces were qualified. The detailed data is in the following table;

|

Item No. |

Size |

Temper |

Rm ≥375 MPa |

Elongation ≥20% |

HR30T ≥53 |

|

1 |

6*1*4000 |

H58 |

421 |

27.8 |

/ |

|

2 |

10*0.5*4000 |

476 |

19.3 |

55.8 |

|

|

3 |

16*1*4000 |

437 |

26.7 |

/ |

|

|

4 |

30*2*4000 |

421 |

27.8 |

67.4 |

|

|

5 |

38*1*4000 |

399 |

36.1 |

/ |

|

|

6 |

50*1*4000 |

414 |

28 |

64.8 |

|

|

7 |

50*2*4000 |

429 |

34.1 |

64.4 |

*Remarks: The elongation is provided by manufacturer but not specified in the standard.

Photo attachment as below

|

|

|

Tension test |

Test pieces |

|

|

|

Hardness test |

Test pieces |

- Dimension inspection

The tubes were qualified according to ASTM B251, and the detailed data is in the following table.

|

Item No. |

Size / mm |

Inspection Amount / pc |

Average OD / mm |

WT / mm |

Length / mm |

Roundness / mm |

|

1 |

6*1*4000 |

5 |

5.96 |

0.98~1 |

4004~4006 |

0.03 |

|

2 |

10*0.5*4000 |

5 |

9.99 |

0.45~0.52 |

4003~4004 |

0.02 |

|

3 |

30*1*4000 |

5 |

29.98~30.01 |

0.91~1.09 |

4005~4006 |

0.05 |

|

4 |

30*2*4000 |

5 |

30.01~30.07 |

1.83~2.18 |

4004 |

0.03 |

|

5 |

50*1*4000 |

5 |

50~50.03 |

0.93~1.04 |

4002~4004 |

0.06 |

|

6 |

50*2*4000 |

5 |

50.04~50.06 |

1.87~2.12 |

4003~4004 |

0.04 |

Photo attachment as below

|

|

|

Measuring OD |

Measuring WT |

|

|

|

|

Measuring length |

|

- Review of Documentation

The mill provided Mill Test Certificate.