Difference Between SCH 40 and SCH 80 Steel pipe

June 16, 2018Aluminum Brass Tubes Inspection report

June 29, 2018

|

INSPECTION REPORT Report No.: MIL 100513-01A2 Issued on: Jun 18th, 2010 Inspection Time: Jun 13-15th, 2010 |

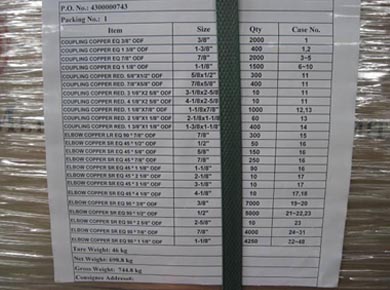

P.O. No.4300000743 |

|

Inspection Subject: |

Copper Fittings |

||

|

Inspector: |

Lin Gaojie |

||

|

Specification: |

As per Sample |

|

|

Visit Summary:

Scope of Inspection

- Visual inspection.

- Quantity and weight

- Dimension

- Packaging

- Documents

- Part photo

Results of inspection to MIL 100513-01A2

- Process Verification

- Visual Inspection

The fittings were good and the details were as followed:

1) All fittings were marked with “MIL” Photo attachment as below

|

|

|

Pipe coupling copper equal |

Pipe coupling copper reducing |

|

|

|

Pipe elbow copper equal 90° |

Pipe elbow copper equal 45° |

|

|

|

End cap copper |

Pipe tee copper |

|

|

|

Pipe trap copper P’type |

Pipe saddle 2 hole |

- Quantity and weight verification

1) The quantity was sufficient Photo attachment as below

|

|

|

|

Weighing |

|

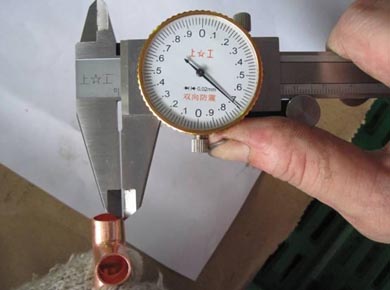

- Dimension inspection

The fittings were qualified according to standard C, though the plustolerance of some fittings with the size upon 3-1/8“ was 0.2mm more than ASME B16.22.

Photo attachment as below

|

|

|

|

Verifying the plug guage |

|

|

|

|

|

Inspecting the inside diameter |

|

|

|

|

|

measuring WT |

|

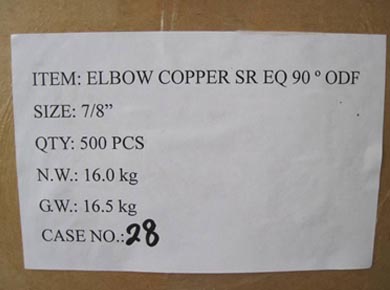

- Packaging inspection

The fittings were encapsulated by the poly bags first, then put into cartons, and bundled by polywood tray. Details as below:

- The packaging was on the witness of us

- There was one label on each poly bag and carton;

- The shipping mark was pasted on the tray;

- All cartons were marked with “MIL”

Photo attachment as below

|

|

|

Poly bag with label |

|

|

|

|

Fittings in the carton |

|

|

|

|

Carton with label |

|

|

|

|

Finished polywood tray |

|

|

|

|

Shipping mark |

|

- Review of Documentation

Raw Material Test Certificate.

- Conclusions:

The inspection results shows that the copper fittings are in full comformity with the client’s samples.