Differences between the characteristics of different grades of alloy steel pipes, and application cases

August 19, 2022

Theoretical weight calculation formula of various steels

August 24, 2022Casing is nested layer by layer, the outermost layer under the deepest and shallowest coarsest, and then step by step deeper, thinner, the above figure is erased the key data of the well depth structure diagram, you can see, the first four openings are casing back to the wellhead, so you see the scene wellhead will not be too large, the diameter should be the inner diameter of the four-open casing, the fifth opening, the thinnest casing, down to the deepest, tailpipe suspension.

First of all, casing is divided into surface casing, intermediate casing, completion casing. The function of the casing mainly has the role of carrying and sealing the formation. Due to the physical properties of the formation and the drilling process, it is necessary to drill a multi-layer casing, after drilling a section of borehole, down into the corresponding size of the casing, and then select a relatively small size drill bit to drill the next small size of the borehole, and then down into the relatively small size of the casing to seal the new formation. The smaller casing on the back is and so on. With the exception of the surface casing, each casing is suspended from the upper casing via the casing head, and the largest casing itself has been used by 30″. In addition, the down casing requires the use of specialized tools, and similar to the wellhead operation tool for drilling down, casings above 7″ require the use of a crane.

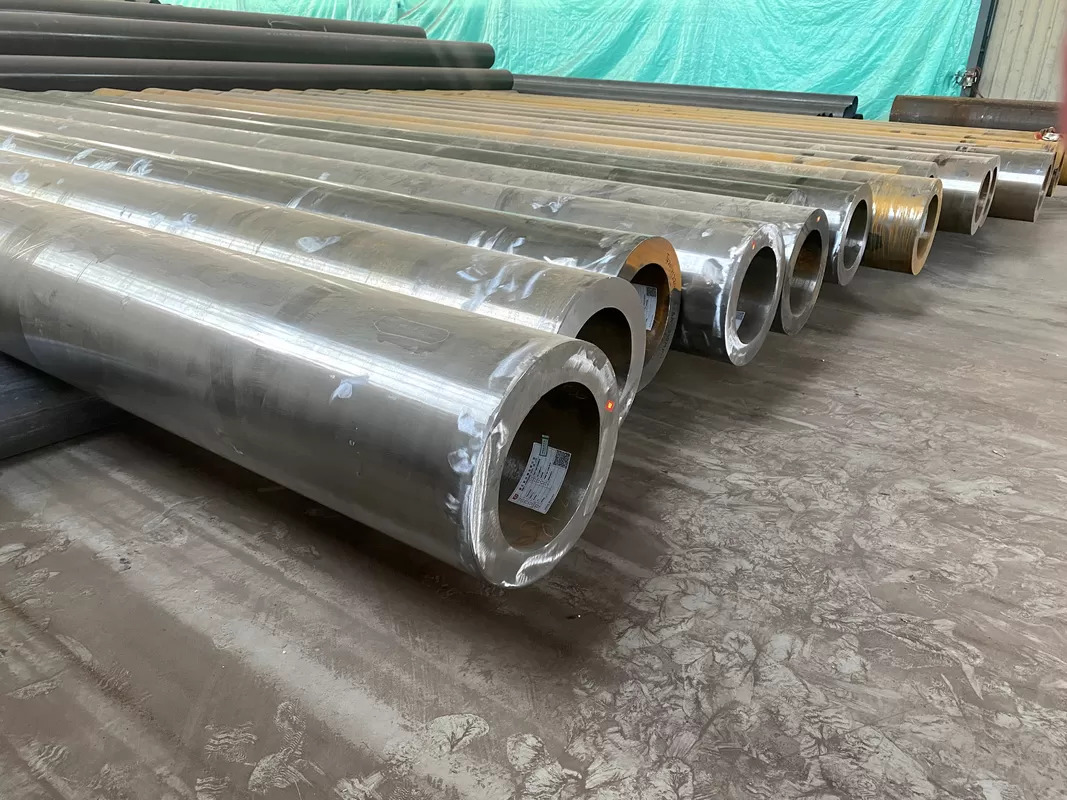

Oil casing operations are placed under the oil well

1, the crane tube should be hoisted one by one, pay attention to the status of the surrounding personnel when lifting, and must use a standard lifting belt.

2. The drill table guard wire is worn with a rope, and the pneumatic winch is placed down, and it is strictly forbidden to throw it directly down to prevent injury.

3. When attaching the accessory, be sure to apply the sealing grease and strictly prevent damage due to misgrid.

4. In the process of lower casing, when the operation is stopped due to repairing equipment, replacing casing, filling mud, etc., the casing should be moved up and down to prevent the casing from sticking to the card.

5. When the casing pliers are buckled, it must be buckled on the back, and it is strictly forbidden to forcibly buckle up after the wrong buckle, and the torque of the upper buckle meets the requirements according to the standard. After the wrong buckle, see if the buckle is damaged, there is a problem to throw down the replacement, if the upper buckle torque reaches the maximum, there are still three buckles or more than three buckles of the casing to shake off the replacement, if the buckle is tightened two times, still can not reach the maximum torque, the sleeve is thrown down to replace.

6. The speed should be controlled during the process of sleeve down, and the lowering speed should not be greater than 30 seconds / root to prevent pressure leakage formation.

7. Require 10 slurries to be filled once, and each time must be filled; The casing must be moved when filling the mud to prevent the occurrence of sticky casing accidents, and the casing must be continuously grouted after entering the stable oblique section. It is strictly forbidden to use the mud pump to prevent the pipeline from being thrown out and injuring people. (Under special circumstances, if a mud pump is used, the protective rope must be tied or the protective chain must be tied)

8. In the process of lower casing, there must be a special person sitting on the post to observe whether there is a well leak (the mud of the lower casing does not return), and the overflow phenomenon (do not return to the mud under the casing).

9. After the casing is completed, check whether the number of remaining casing roots is correct.

10. After the casing is completed, fill the mud with mud at one time and then open the pump, and the casing must be loosened when filling the mud.