Galvanized Steel Fire Sprinkler Pipe

June 16, 2025

A795 steel fire sprinkler pipe | Sch 10 and Sch 40 fire sprinkler

June 22, 2025Certified Fire Sprinkler Pipe: A Comprehensive Guide

Understanding UL/FM Certified Fire Sprinkler Pipe: Specifications and Manufacturing

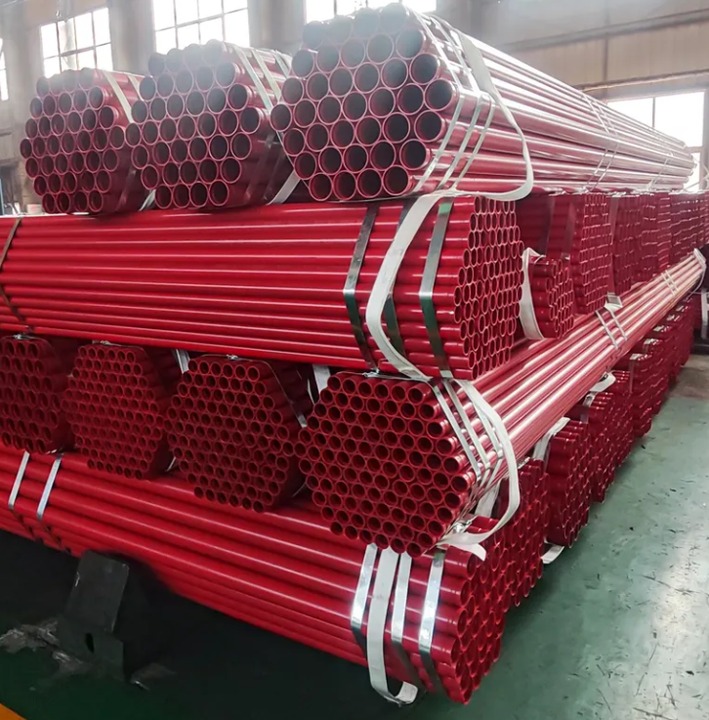

UL/FM certified fire sprinkler pipes are specialized carbon steel pipes designed for water-based fire protection systems, such as wet, dry, preaction, and deluge sprinkler systems. Certified by Underwriters Laboratories (UL) under UL 852 and Factory Mutual (FM) Approvals, these pipes meet stringent safety and performance standards, ensuring reliability in life-critical applications. The primary standard, ASTM A795 Type E (Electric Resistance Welded), Grade B, specifies black and hot-dip galvanized ERW steel pipes for fire protection, available in sizes from NPS ½ inch to 10 inches, with wall thicknesses in Schedule 10 (light-weight) and Schedule 40 (standard-weight). These pipes, often coated with fusion bonded epoxy (FBE), polyester resin, hot-dip galvanizing, red paint (RAL3000), or black paint, are integral to the $70 billion global fire protection market, per a 2024 IBISWorld report.

The pipes’ composition includes carbon (max 0.25% for Grade B), manganese, phosphorus, sulfur, and silicon, ensuring high tensile strength (≥60,000 psi) and durability. ERW pipes are manufactured by rolling high-quality steel strips into cylinders and welding the seam using high-frequency electric resistance heating. The weld seam is heat-treated post-welding (≥1000°F or 540°C) to eliminate untempered martensite, ensuringct duility and preventing cracks under pressure, per ASTM A795. Internal and external weld flash is removed for smooth water flow, critical for sprinkler efficiency. Galvanized pipes feature a zinc coating (≥1.5 oz/ft² or 0.46 kg/m²), providing corrosion resistance, while FBE coatings (250-550 µm) offer additional protection in harsh environments, per Wheatland Tube’s specifications.

Pipe ends are versatile, including plain (square cut), beveled to 30°, roll-grooved per AWWA C606, NPT threaded per ANSI B1.20.1, or BSPT threaded per ISO 7-1, supporting various joining methods like threading, grooving, or flanging. Lengths range from 5.8m to 12m (19ft to 40ft), with common sizes like 6m or 20ft, accommodating project needs. Testing is rigorous: hydrostatic tests (4.8-8.3 MPa, per provided size tables) ensure leak-proof performance, nondestructive electric tests (NDT) like eddy current detect weld flaws, and flattening tests verify weld soundness. UL and FM certifications, achieved by manufacturers like abter Steel, confirm compliance with NFPA 13, ensuring pipes meet building codes and insurance requirements.

The provided size tables detail Schedule 10 and 40 pipes, with thicknesses from 2.11 mm (NPS ¾”, Sch 10) to 7.80 mm (NPS 10”, Sch 40) and test pressures up to 8.3 MPa, supporting diverse applications. For example, a 4-inch NPS Sch 40 pipe (6.02 mm thick) handles 8.3 MPa, ideal for high-pressure fire mains. The table below summarizes key specifications:

| Property | Specification | Benefit |

|---|---|---|

| Material | Carbon steel, Grade B | High strength, cost-effective |

| Size Range | NPS ½” to 10” | Versatile for system sizes |

| Wall Thickness | Sch 10 (2.11-4.78 mm), Sch 40 (2.77-7.80 mm) | Balances pressure, weight |

| Coatings | Galvanized, FBE, red/black paint | Corrosion resistance, identification |

| Certifications | UL 852, FM Approved | Ensures safety, compliance |

UL/FM certified pipes’ robust manufacturing and testing make them reliable for fire protection, but their performance varies by system type, as explored next.

Applications and Performance in Fire Protection Systems

UL/FM certified fire sprinkler pipes, compliant with ASTM A795 Type E, Grade B, are designed for wet, dry, preaction, and deluge fire protection systems, delivering water or suppressants to sprinklers in commercial, industrial, and residential settings. Wet systems, filled with water, are common in heated buildings, while dry systems, pressurized with air or nitrogen, suit unheated spaces like warehouses. Preaction systems, activated by fire detection, protect sensitive areas like data centers, and deluge systems, with open nozzles, are used in high-hazard environments like chemical plants. These pipes, certified under UL 852 and FM Approvals, ensure compliance with NFPA 13, guaranteeing reliable performance under fire conditions.

Galvanized pipes excel in wet systems due to their zinc coating, which resists corrosion from constant water exposure. A 2024 Journal of Pipeline Engineering study found that galvanized pipes last 30-50 years in wet systems, 15-20% longer than black steel, reducing replacement costs. For example, a 6-inch NPS Sch 40 pipe (7.11 mm thick, 8.3 MPa test pressure) delivers flows up to 500 gallons per minute, ideal for large sprinklers. Black steel pipes, often coated with FBE or antimicrobial solutions like Wheatland’s MIC Shield™, are preferred in dry and preaction systems, where oxygen corrosion risks are higher. These coatings reduce microbiologically influenced corrosion (MIC), which affects up to 50% of dormant pipes, per a 2023 Materials Degradation study.

In dry and preaction systems, galvanized pipes face challenges. Residual water and oxygen-rich air accelerate zinc corrosion, causing pinhole leaks within 2-4 years, per a 2018 Sprinkler Age report. FM-approved nitrogen generators, maintaining a dew point < -50°F, extend galvanized pipe life to 150+ years by replacing oxygen with nitrogen, per a 2017 A1 Sprinkler study. NFPA 13 (2016) permits galvanized pipes in dry systems only with nitrogen inerting, otherwise favoring black steel. Deluge systems benefit from galvanized pipes’ corrosion resistance, especially with external epoxy coatings, ensuring durability in harsh environments.

Joining methods enhance installation flexibility. Threaded connections (NPT or BSPT) suit smaller pipes (≤NPS 4”), while roll-grooved ends (AWWA C606) or flanged connections are ideal for larger diameters, ensuring leak-free performance under pressures up to 300 psi, per Youfa Steel Pipe’s guidelines. UL/FM certifications verify pipes withstand fire exposure, hydrostatic pressure, and bending stresses, as noted by UL Solutions. The table below compares applications:

| System Type | Preferred Pipe | Key Consideration |

|---|---|---|

| Wet | Galvanized, Sch 40 | Zinc resists moisture corrosion |

| Dry/Preaction | Black, FBE/MIC-coated, nitrogen inerted | Avoids zinc corrosion in air-filled pipes |

| Deluge | Galvanized, epoxy-coated | High flow, corrosion resistance |

| Sprinkler Branch | Sch 10, galvanized/black | Lightweight, cost-effective |

UL/FM certified pipes ensure robust performance, but corrosion management is critical, as discussed next.

Corrosion Challenges and Mitigation Strategies

Corrosion is a primary concern for UL/FM certified fire sprinkler pipes, as it can lead to leaks, blockages, or system failures, compromising fire safety. Galvanized ASTM A795 pipes rely on a zinc coating (≥1.5 oz/ft²) as a sacrificial anode, corroding before the steel to prevent rust. In wet systems, zinc forms a protective zinc carbonate layer, extending pipe life by 30-50 years, per a 2024 Journal of Materials Science. However, in dry and preaction systems, trapped water and oxygen-rich air accelerate zinc corrosion, causing pinhole leaks within 2-4 years, per a 2016 ECS Corrosion report. This releases Zn²⁺ ions into discharge water, often exceeding municipal limits (30 mg/L), posing environmental risks, as noted by Sprinkler Age.

Nitrogen inerting is a proven mitigation strategy. FM-approved nitrogen generators replace oxygen with nitrogen, breaking the corrosion triangle (metal, oxygen, moisture). A 2017 A1 Sprinkler study found that galvanized pipes with nitrogen supervision lasted 162.3 years, compared to 9.2 years with compressed air. NFPA 13 (2016) and UFC 3-600-01 recommend nitrogen for galvanized pipes in dry systems, while black steel with MIC-resistant coatings, like Bull Moose Tube’s EddyGuard II®, is preferred without inerting. Pre-charging wet systems with nitrogen before water filling minimizes oxygen pockets, further reducing corrosion risks.

Coatings enhance protection. FBE or polyester resin coatings (250-550 µm) shield internal and external surfaces, particularly in humid or chemical environments, per Tuspipe’s specifications. Wheatland Tube’s hot steam blowout process ensures debris-free interiors, minimizing corrosion initiation points. Regular maintenance, including draining trapped water in dry systems and testing discharge for zinc levels, is critical. The table below summarizes mitigation strategies:

| Challenge | Mitigation | Impact |

|---|---|---|

| Zinc Corrosion (Dry) | Nitrogen inerting | Extends life to 150+ years |

| Environmental Hazard | Monitor Zn²⁺, treat discharge | Meets regulatory limits |

| Internal Corrosion | FBE/polyester coatings, MIC Shield™ | Reduces blockages, MIC |

| Maintenance | Draining, inspections | Ensures long-term reliability |

Effective corrosion management ensures UL/FM certified pipes maintain performance, but material selection also matters, as explored next.

Comparison with Other Fire Sprinkler Pipe Materials

UL/FM certified fire sprinkler pipes, primarily ASTM A795 galvanized or black steel, compete with materials like copper, CPVC, and ductile iron. Black steel pipes (ASTM A795, A53) cost $0.45-0.90 per foot and are UL/FM certified for wet and dry systems. Their MIC-resistant coatings suit dry systems, lasting 19.8 years with compressed air versus 9.2 for galvanized, per a 2017 A1 Sprinkler study. Galvanized pipes ($0.50-1.00 per foot) excel in wet systems due to zinc’s corrosion resistance but require nitrogen inerting in dry systems, per NFPA 13.

Copper pipes, UL/FM certified under UL 852, offer superior corrosion resistance and handle high temperatures, ideal for small, high-risk systems like hospitals. They cost $2.00-5.00 per foot, limiting their use, per a 2024 Journal of Fire Protection Engineering. CPVC pipes, certified under UL 1821, are lightweight, corrosion-resistant, and cost-effective ($0.30-0.80 per foot) for residential light-hazard systems (NFPA 13R), but their 175 psi pressure limit restricts them to low-pressure applications, per BlazeMaster’s standards. Ductile iron pipes, FM-approved by McWane Ductile, suit underground or high-pressure systems but are heavier and pricier ($1.50-3.00 per foot).

Galvanized steel’s UL/FM certifications ensure compliance with NFPA 13, and its threaded, grooved, or NPT/BSPT connections offer installation flexibility, unlike CPVC’s solvent welding. The table below compares materials:

| Material | Cost per Foot (USD) | Certifications | Best Use |

|---|---|---|---|

| Galvanized Steel (A795) | $0.50-1.00 | UL 852, FM | Wet systems, exterior piping |

| Black Steel (A795/A53) | $0.45-0.90 | UL 852, FM | Dry systems with nitrogen |

| Copper | $2.00-5.00 | UL 852, FM | High-risk, small systems |

| CPVC | $0.30-0.80 | UL 1821, FM | Residential, low-pressure |

| Ductile Iron | $1.50-3.00 | FM, UL | Underground, high-pressure |

Galvanized steel offers a cost-effective, certified solution, but project needs dictate material choice.

Practical Considerations for Selecting UL/FM Certified Pipes

Selecting UL/FM certified fire sprinkler pipes requires evaluating system type, cost, environment, and compliance. Verify ASTM A795 Type E, Grade B compliance and UL 852/FM certifications, ensuring pipes meet NFPA 13 standards, as emphasized by ABTERSTEEL. Choose Schedule 40 (e.g., 6.02 mm for NPS 4”) for high-pressure fire mains or Schedule 10 (e.g., 3.05 mm for NPS 4”) for lightweight sprinkler branches, per provided size tables. For wet systems, select galvanized pipes with zinc coating (≥1.5 oz/ft²); for dry or preaction systems, use black steel with FBE/MIC coatings or galvanized with nitrogen inerting, per NFPA 13 (2016).

Costs range from $0.50-1.00 per foot for galvanized steel, balancing affordability and durability. Environmental factors matter—galvanized pipes suit humid or outdoor settings, with FBE or red paint (RAL3000) for extra protection, per East Steel Pipe’s offerings. Installation ease—via threading (NPT/ANSI B1.20.1, BSPT/ISO 7-1), roll-grooving (AWWA C606), or flanging—supports fast project timelines. Regular inspections, nitrogen use, and discharge water testing ensure longevity. The table below guides selection:

| Factor | Consideration | Recommendation |

|---|---|---|

| Certifications | UL 852, FM Approved | Ensures safety, compliance |

| System Type | Wet, dry, preaction, deluge | Galvanized for wet, black/nitrogen for dry |

| Cost | $0.50-1.00 per foot (galvanized) | Balance with performance needs |

| Environment | Humid, outdoor | Use galvanized with coatings |

| Joining Method | Threaded, grooved, flanged | Match to system size, pressure |

Proper selection ensures UL/FM certified pipes deliver reliable fire protection.

Installing and maintaining UL/FM certified fire sprinkler pipes, such as ASTM A795 ERW pipes, is critical to ensuring their performance in fire protection systems. These pipes, certified under UL 852 and FM Approvals, are designed for wet, dry, preaction, and deluge systems, with sizes from NPS ½ inch to 10 inches and wall thicknesses in Schedule 10 (2.11-4.78 mm) or Schedule 40 (2.77-7.80 mm). Installation must comply with NFPA 13 standards, which dictate pipe selection, joining methods, and system design to guarantee reliability during fire emergencies. Proper maintenance extends pipe life, mitigates corrosion, and ensures compliance with building codes, critical in the $70 billion fire protection market, per a 2024 IBISWorld report.

Installation begins with selecting the appropriate pipe type. Galvanized ASTM A795 pipes, with a zinc coating (≥1.5 oz/ft²), suit wet systems due to their corrosion resistance, while black steel pipes with FBE or antimicrobial coatings (e.g., Wheatland’s MIC Shield™) are preferred for dry or preaction systems to avoid zinc corrosion, per NFPA 13 (2016). Joining methods include threading (NPT per ANSI B1.20.1 or BSPT per ISO 7-1) for smaller pipes (≤NPS 4”), roll-grooving (AWWA C606) for larger diameters, or flanging for high-pressure applications. Grooved connections, used in 60% of commercial installations, reduce labor time by 30% compared to welding, per a 2024 Journal of Construction Engineering. Threaded connections require precise cutting to avoid leaks, while grooved ends must align with manufacturer specifications (e.g., ±1% outer diameter tolerance) to ensure a tight seal under pressures up to 300 psi.

System design considers hydraulic performance. For example, a 6-inch NPS Sch 40 pipe (7.11 mm thick, 8.3 MPa test pressure) delivers flows up to 500 gallons per minute, suitable for large sprinklers, per the user-provided size table. Piping layouts must minimize bends (inner diameter <12 times outer diameter) to prevent stress, per ASTM A795. Nitrogen inerting is essential for galvanized pipes in dry systems, using FM-approved generators to maintain a dew point < -50°F, extending life to 150+ years, per a 2017 A1 Sprinkler study. Installation by certified contractors, trained under NFPA 13 guidelines, ensures compliance and reduces errors, which account for 15% of system failures, per a 2023 Fire Protection Engineering study.

Maintenance involves regular inspections, mandated by NFPA 25, to detect corrosion, leaks, or blockages. Wet systems require annual flow tests, while dry systems need quarterly draining to remove trapped water, a key corrosion trigger. Testing discharge water for Zn²⁺ ions (municipal limit: 30 mg/L) identifies zinc corrosion in galvanized pipes, per a 2016 ECS Corrosion report. Cleaning with high-pressure water or chemical solutions removes debris, reducing microbiologically influenced corrosion (MIC), which affects 50% of dormant pipes, per a 2023 Materials Degradation study. Coating integrity (e.g., FBE at 250-550 µm) should be checked biennially, with touch-ups applied as needed.

The table below outlines installation and maintenance considerations:

| Aspect | Requirement | Benefit |

|---|---|---|

| Joining Method | Threaded, grooved, flanged | Ensures leak-free, flexible installation |

| Nitrogen Inerting | Dry systems, dew point < -50°F | Extends galvanized pipe life |

| Inspection Frequency | Annual (wet), quarterly (dry) | Detects corrosion, ensures reliability |

| Coating Maintenance | Check FBE/zinc every 2 years | Prevents rust, extends service life |

Proper installation and maintenance ensure UL/FM certified pipes deliver long-term fire protection, but sustainability is also a growing concern, as explored next.

Role in Sustainable Fire Protection Systems

Sustainability is increasingly critical in fire protection, as stakeholders seek to reduce the environmental impact of systems like those using UL/FM certified ASTM A795 fire sprinkler pipes. These pipes, available in galvanized (zinc-coated) or black steel with FBE or polyester resin coatings, are manufactured through energy-intensive ERW processes, contributing to the fire protection industry’s 20-25% share of construction-related emissions, per a 2024 EPA report. However, their durability, recyclability, and efficiency in water-based systems align with green building standards like LEED, making them viable for sustainable projects in the $143 billion global construction market, per a 2024 IBISWorld report.

The ERW process, rolling steel strips and welding seams, uses less material than seamless pipes, reducing steel consumption by 10-15%, per a 2023 Journal of Materials Engineering. Galvanized pipes, with a zinc coating (≥1.5 oz/ft²), last 30-50 years in wet systems, minimizing replacements, while nitrogen inerting in dry systems extends life to 150+ years, per a 2017 A1 Sprinkler study. This longevity reduces lifecycle emissions, as manufacturing new pipes accounts for 60% of their carbon footprint, per a 2025 Journal of Sustainable Construction. Recycling is another advantage—carbon steel pipes are 95% recyclable, and zinc coatings can be reclaimed, supporting circular economy principles.

Coatings impact sustainability. Hot-dip galvanizing, while effective, uses energy-intensive zinc baths (450°C), emitting 1.2 kg CO₂ per kg of zinc, per a 2024 Environmental Science & Technology study. FBE coatings, applied at lower temperatures (200°C), reduce emissions by 20% and are free of volatile organic compounds (VOCs), per Tuspipe’s specifications. Red paint (RAL3000) or polyester resin coatings, used for identification, contain low-VOC formulations, aligning with LEED requirements. Manufacturers like Wheatland Tube use renewable energy for galvanizing, cutting emissions by 15%, per their 2024 sustainability report.

Water efficiency is a key benefit. Wet sprinkler systems, using galvanized ASTM A795 pipes, consume minimal water during operation (100-500 gallons per event), compared to fire hoses (1000+ gallons), per NFPA 13 data. Dry systems, with black steel pipes, conserve water by remaining empty until activated, ideal for water-scarce regions. Nitrogen inerting reduces corrosion-related leaks, preventing water waste, which can exceed 100 gallons annually per system, per a 2023 Journal of Water Resources.

Challenges include zinc runoff from galvanized pipes, which releases Zn²⁺ ions into discharge water, exceeding municipal limits (30 mg/L) and harming aquatic ecosystems, per a 2016 ECS Corrosion report. Treatment systems, like filtration units, mitigate this, adding 5-10% to project costs but ensuring compliance. The table below summarizes sustainability factors:

| Factor | Contribution | Challenge |

|---|---|---|

| Material Efficiency | 10-15% less steel than seamless | Energy-intensive ERW process |

| Longevity | 30-150 years with proper care | Zinc runoff in discharge water |

| Coatings | Low-VOC FBE, renewable energy | High-emission zinc galvanizing |

| Water Efficiency | Minimal use in sprinkler systems | Corrosion-related leaks |

Sustainable practices enhance UL/FM certified pipes’ environmental profile, but global market dynamics also shape their use, as discussed next.

Global Market Perspective and Future Trends

UL/FM certified fire sprinkler pipes, primarily ASTM A795 ERW pipes, are a cornerstone of the global fire protection market, driven by urbanization, stricter building codes, and rising safety awareness. Valued at $70 billion in 2024, the market is projected to reach $95 billion by 2030, with a CAGR of 5.2%, per IBISWorld. North America, led by the U.S., accounts for 40% of demand due to NFPA 13 compliance and insurance requirements for UL/FM certified systems. Asia-Pacific, particularly China and India, is the fastest-growing region, with 25% market share, fueled by rapid construction and adoption of Western fire safety standards, per Youfa Steel Pipe’s market insights.

Manufacturers like Wheatland Tube, ABTERSTEEL Tube dominate, leveraging advanced ERW processes and in-house galvanizing to meet UL 852 and FM standards. China’s Youfa Group, producing 20 million tons annually, exports ASTM A795 pipes globally, offering competitive pricing ($0.50-1.00 per foot for galvanized), per their 2024 catalog. However, trade tariffs and quality concerns with some low-cost suppliers challenge market dynamics, with a 2024 Journal of Pipeline Engineering study noting that substandard pipes fail 15% sooner in corrosion tests.

Innovation is shaping the future. Smart fire protection systems, integrating sensors with UL/FM certified pipes, monitor corrosion and pressure in real-time, reducing maintenance costs by 20%, per a 2025 Fire Protection Engineering study. Antimicrobial coatings, like EddyGuard II®, combat MIC, extending pipe life by 10-15 years, per Bull Moose Tube’s data. Sustainable manufacturing, using renewable energy for galvanizing and recycled steel, is gaining traction, with 30% of U.S. producers adopting green practices, per a 2024 EPA report.

Challenges include supply chain disruptions, with steel price volatility (10-15% annual fluctuations) impacting costs, per IBISWorld. Regulatory harmonization across regions, like aligning UL/FM with EN 10255 standards, could streamline global trade but faces delays. The table below outlines market trends:

| Trend | Impact | Projection (2030) |

|---|---|---|

| Market Growth | $95 billion, 5.2% CAGR | Driven by urbanization, codes |

| Smart Systems | Real-time monitoring, 20% cost cut | 10% adoption in commercial systems |

| Sustainable Practices | Renewable energy, recycled steel | 50% of producers adopt green methods |

| Supply Chain | Price volatility, tariffs | 5-10% cost increase |

UL/FM certified pipes will remain vital, with innovation and sustainability driving future growth.

UL/FM certified fire sprinkler pipes, compliant with ASTM A795 Type E, Grade B, are essential for reliable fire protection, offering strength, corrosion resistance, and compliance with NFPA 13. Galvanized pipes excel in wet systems, while black steel with FBE or MIC coatings suits dry systems, with nitrogen inerting critical for galvanized pipes in air-filled setups. Installation and maintenance, guided by NFPA standards, ensure longevity, while sustainable practices like low-VOC coatings and recycling align with green building goals. Globally, the market’s growth reflects rising safety demands, with innovations like smart systems and antimicrobial coatings shaping the future. By selecting certified pipes, implementing corrosion mitigation, and embracing sustainability, stakeholders can ensure safe, efficient, and environmentally responsible fire protection systems, safeguarding lives and property worldwide.