Zinc-Coated Square Structural Hollow Section (SHS)

December 2, 2025

Bimetallic Alloy Lined Composite Steel Pipe: Inner and Outer Pipe Material Analysis

December 9, 2025The Fusion of Necessity and Economy: Abtersteel’s Bimetallic Corrosion-Resistant Alloy Lined Composite Steel Pipe

The fundamental challenge in designing piping systems for the energy, chemical, and metallurgical sectors lies in navigating an inherent contradiction: the need for materials that simultaneously possess high structural integrity and pressure containment capabilities—typically satisfied by robust, cost-effective carbon steel—while also offering absolute resistance to extremely aggressive chemical agents, high temperatures, and complex corrosive environments—a domain reserved for expensive, highly alloyed materials like stainless steels and nickel-based superalloys. Traditional solutions forced a difficult choice: either utilize costly solid corrosion-resistant piping, accepting the massive capital expenditure and the material’s often inferior mechanical strength, or rely on non-metallic linings, which are highly susceptible to mechanical damage, thermal cycling failure, and abrasive wear. Abtersteel’s successful development and commercialization of the Bimetallic Corrosion-Resistant Alloy Lined Composite Steel Pipe represents a technological paradigm shift, resolving this contradiction through advanced metallurgical bonding that seamlessly integrates the structural strength of the outer carbon steel shell with the superior, tailored chemical resistance of an inner liner—be it an ultra-low carbon stainless steel or an advanced SHS nickel-based alloy. This integrated approach delivers verified performance at a fraction of the cost, making previously prohibitively expensive material solutions economically viable for large-scale industrial deployment, achieving cost savings as dramatic as two-thirds for stainless steel systems and an astonishing one-sixth for nickel-based alloy systems compared to their solid counterparts.

1. The Economic Imperative and the Metallurgical Solution: An Integrated Design Philosophy

The core innovation underlying Abtersteel’s composite piping is the realization of a true metallurgical bond between the liner and the exterior steel pipe. This is not a mere mechanical fit or a chemical adhesive layer; it is a permanent, inter-diffused joint that ensures the liner and the pipe act as a single, structurally unified component. This distinction is critical because it eliminates the risk of liner collapse, buckling, or thermal separation during rapid temperature and pressure fluctuations—common failure modes in non-metallurgically bonded systems. The composite structure fundamentally leverages the best characteristics of both materials: the outer layer (typically high-strength, low-cost $\text{A}106$ or $\text{A}335$ carbon steel) handles the vast majority of the pressure and external mechanical loads, while the thin inner liner (the expensive, specialty alloy) provides the complete, impermeable barrier against the corrosive process fluid.

The strategic genius lies in the economic outcome: because the pressure integrity is derived from the thick, low-cost outer steel, the internal corrosion barrier can be made significantly thinner than a solid alloy pipe designed to handle the same pressure. This optimized material distribution is the source of the profound cost advantage. Abtersteel has focused its development efforts on two distinct liner technologies to cover the full spectrum of industrial corrosion challenges, recognizing that no single alloy is optimal for all environments. The first solution targets general, yet aggressive, chemical processes requiring robust stainless steel resistance, while the second targets the most extreme, high-temperature chemical environments where only nickel-based superalloys can survive.

2. Stainless Steel Lined Pipes: The Intergranular Corrosion Defense (Ultra-Low Carbon Focus)

For the majority of corrosive applications in the petrochemical and chemical industries—where the process media may involve acids, caustic solutions, or chlorides at moderate temperatures—stainless steel (SS) offers the necessary resistance. However, standard austenitic stainless steels, particularly those used in welded pipe systems, possess a fundamental Achilles’ heel: intergranular corrosion (IGC).

IGC is a localized, catastrophic failure mechanism triggered when standard SS (like $304$ or $316$) is exposed to temperatures between $450^{\circ}\text{C}$ and $850^{\circ}\text{C}$—a range commonly encountered during welding or subsequent stress-relieving heat treatments required for the thick outer carbon steel shell. In this sensitized temperature zone, carbon atoms within the stainless steel matrix migrate to the grain boundaries and precipitate as Chromium Carbides ($\text{Cr}_{23}\text{C}_{6}$). This precipitation consumes chromium locally, resulting in a chromium-depleted zone immediately adjacent to the grain boundaries. Since chromium is the element responsible for stainless steel’s passivity (its protective oxide layer), the grain boundaries become vulnerable paths for corrosive attack, leading to the rapid, deep penetration of corrosion and eventual structural failure, even in mildly aggressive environments.

Abtersteel’s technological mitigation focuses on the source: the use of Ultra-Low Carbon (L-grade) Stainless Steel (such as $\text{TP}304\text{L}$ or $\text{TP}316\text{L}$) for the liner. By strictly controlling the carbon content below $0.03\%$ (often aiming for even lower values), the material effectively starves the sensitization process. There simply is not enough carbon available in the matrix to form the damaging chromium carbides, ensuring that the essential chromium concentration remains uniform at the grain boundaries. This critical chemical constraint ensures that the inner liner retains its full, intrinsic resistance to intergranular corrosion after the inevitable thermal cycling associated with the metallurgical bonding process and the necessary welding of the exterior carbon steel shell during pipe fabrication and installation. This focus on chemical purity in the liner material guarantees that the finished composite pipe maintains the expected corrosion resistance, validating the structural integrity of the entire system and delivering a verified cost-to-performance ratio of approximately $1/3$ the cost of solid stainless steel piping.

3. Nickel-Based Alloy Lined Pipes: Conquering Extreme Environments (SHS Technology and Thermal Stress)

For environments that exceed the chemical or thermal resistance capabilities of even the most sophisticated stainless steels—such as high-concentration reducing acids (e.g., hydrochloric or sulfuric acid), media containing high concentrations of chlorides at elevated temperatures, or extremely hot flue gas containing sulfur and nitrogen compounds—the solution must pivot to Nickel-Based Superalloys. These alloys, rich in nickel, chromium, and molybdenum (e.g., the $\text{CrMoFe}$ family), possess unparalleled resistance to pitting, crevice corrosion, stress corrosion cracking (SCC), and, critically, superior high-temperature stability.

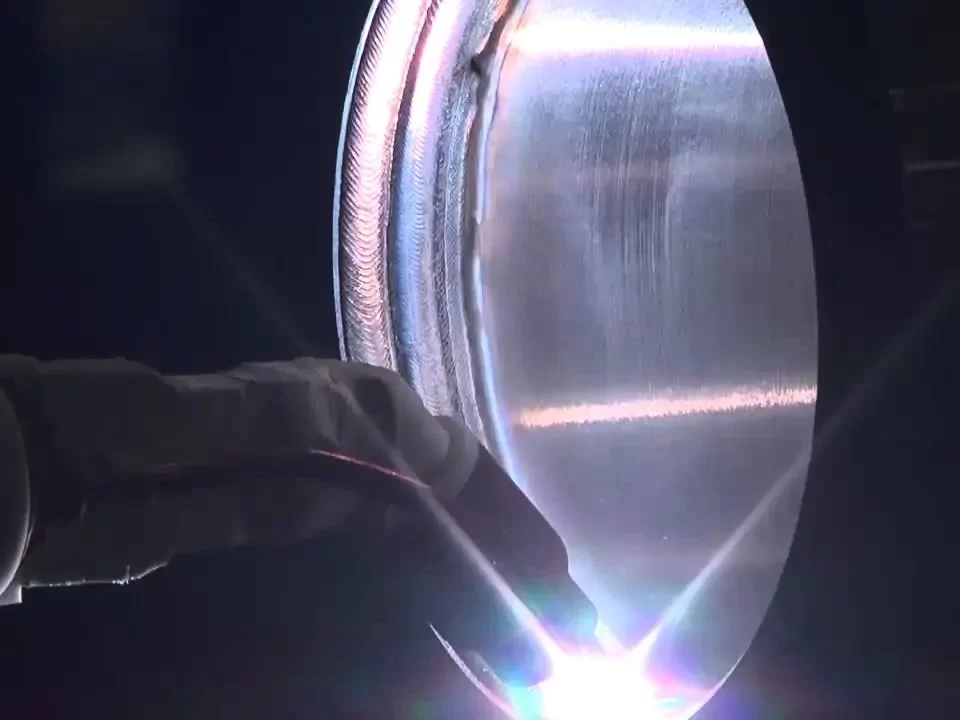

The demands of these environments—common in hydroprocessing, sulfur recovery units, and specialized chemical reactors—justify the five-fold price premium of nickel alloys over stainless steel. The challenge, however, is that solid nickel alloy pipe is astronomically expensive, rendering large-scale systems economically untenable. Abtersteel’s advanced lining technology, implicitly utilizing methods such as Self-propagating High-temperature Synthesis (SHS) or similar controlled explosive/diffusion bonding techniques to achieve the metallurgical bond, provides a pathway to utilize this superior material cost-effectively.

The technical justification for choosing nickel alloys goes far beyond simple corrosion resistance:

-

High-Temperature Chemical Resistance: Nickel alloys exhibit exceptional resistance to oxidation, sulfidation, nitridation, and carburization at temperatures well above $600^{\circ}\text{C}$, failure modes that rapidly degrade stainless steel.

-

Excellent Weldability: Unlike some high-strength steels, nickel alloys maintain good weldability, simplifying the process of creating the final composite structure.

-

Crucial Thermal Stability: A major engineering benefit that Abtersteel exploits is the fact that nickel-based alloys possess a thermal expansion coefficient that is remarkably close to that of the outer carbon steel layer. This similarity is an absolute mechanical advantage during the bonding process and throughout the pipe’s operational life. When the pipe heats and cools, the minimal thermal stress mismatch between the inner liner and the outer shell prevents the high stresses that can lead to cracking, delamination, or liner buckling—a failure mode particularly relevant in thermally cycling industrial processes. This combined superiority—unparalleled corrosion resistance coupled with thermal compatibility—justifies the cost of the raw liner material and, when manufactured using Abtersteel’s method, results in the staggering cost saving of one-sixth the price of a solid nickel alloy pipe.

4. Manufacturing Integrity, Performance Assurance, and Economic Trade-offs

The entire commercial and structural validity of the bimetallic composite pipe rests upon the integrity of the metallurgical bond. The structural engineer must have absolute assurance that the liner will not separate from the outer shell under the combined axial, hoop, and thermal stresses of operational service. Abtersteel’s manufacturing process incorporates stringent quality control metrics to verify this bond:

-

Bond Strength Testing: Samples are routinely subjected to shear strength testing to ensure the metallurgical bond interface exceeds the required minimum strength, often testing the failure mechanism to ensure it occurs within the weaker base material rather than the bond line itself.

-

Non-Destructive Testing (NDT): Every length of composite pipe is subjected to full-body Ultrasonic Testing (UT). The UT process verifies the continuity of the bond line along the entire length and circumference, flagging any minute areas of delamination or lack of fusion, ensuring zero tolerance for bond imperfections.

-

Pressure and Mechanical Testing: The final composite pipe is subjected to standard hydrostatic and mechanical tests, confirming that the structural performance of the outer carbon steel shell meets the relevant structural codes (e.g., ASME B31.3), while the liner remains structurally attached and uncompromised.

The economic decision between the two product lines—Stainless Steel Lined vs. Nickel-Based Alloy Lined—is a calculated trade-off based on the severity of the service environment. If the process is corrosive but temperature is moderate and chloride levels are manageable, the Stainless Steel Lined Pipe provides the most cost-effective solution (1/3 cost), delivering sufficient resistance without the higher cost of nickel. However, when the environment is known to induce high-temperature corrosion, $\text{SCC}$, or rapid oxidation, the only economically feasible option for a long service life is the Nickel-Based Alloy Lined Pipe, where the initial high material cost of the liner is amortized by the $1/6$ manufacturing cost and decades of assured, uninterrupted service. This customized material offering ensures that the client receives the minimal necessary level of corrosion resistance without paying for material that is structurally redundant.

| Feature | Stainless Steel Lined Pipe (Representative Grade: 316L) | Ni-Based Alloy Lined Pipe (Representative Grade: NiCrMoFe Alloy) |

| Outer Pipe Material | Carbon Steel (e.g., $\text{A}106\text{ Gr B}, \text{A}335\text{ Gr P}11$) | Carbon Steel (e.g., $\text{A}106\text{ Gr B}, \text{A}335\text{ Gr P}22$) |

| Inner Liner Material | Ultra-Low Carbon Austenitic Stainless Steel ($\text{L}$-Grade) | Nickel-Chromium-Molybdenum-Iron Alloy (Superalloy) |

| Bonding Method | Metallurgical Bonding (Diffusion/Explosion/Roll Cladding) | Advanced Metallurgical Bonding (e.g., SHS or similar process) |

| Primary Corrosion Focus | Intergranular Corrosion and general acid/chloride corrosion | High-Temperature Oxidation/Sulfidation, Pitting, $\text{SCC}$ |

| Key Liner Advantage | Ultra-Low $\text{C}$ content prevents sensitization/Cr depletion | Superior $\text{T}$ stability and low thermal expansion mismatch |

| Cost Savings Ratio | $\approx 1/3$ the cost of solid SS pipe | $\approx 1/6$ the cost of solid $\text{Ni}$-Alloy pipe |

| Applicable Standard | Based on $\text{ASTM} \text{ A}264/\text{A}263$ (Clad Plate Concepts) | Customized $\text{API}/\text{ASME}$ specifications for advanced cladding |

| Liner Chemical Composition (Representative Example: 316L & Ni-Alloy) | 316L (Max/Range) | NiCrMoFe Alloy (Approximate Range) |

| Carbon (C) | $\leq 0.03\%$ (Crucial for $\text{IGC}$ defense) | $\leq 0.08\%$ |

| Chromium (Cr) | $16.0\% – 18.0\%$ | $20.0\% – 23.0\%$ |

| Nickel (Ni) | $10.0\% – 14.0\%$ | $\text{Balance}$ ($\sim 58.0\% – 65.0\%$) |

| Molybdenum (Mo) | $2.0\% – 3.0\%$ | $8.0\% – 10.0\%$ |

| Iron (Fe) | $\text{Balance}$ | $2.5\% – 7.0\%$ |

| Other Elements | $\text{P, S, Si}$ controlled | $\text{Nb, W}$ for strengthening/corrosion resistance |

| Performance and Application Overview | Stainless Steel Lined (SS) | Nickel-Based Alloy Lined (Ni-Alloy) |

| Tensile Requirements | Governed by Outer Steel (e.g., $\text{A}106$) | Governed by Outer Steel (e.g., $\text{A}106$) |

| Heat Treatment Req. | $\text{PWHT}$ applied to Outer Steel; Liner must resist sensitization | $\text{PWHT}$ applied to Outer Steel; Liner resists thermal degradation |

| Typical Application | Chemical processing, mild sour service, water treatment | HF/H${2}\text{SO}{4}$ service, high-temperature reactors, severe sour gas |

| Key Features | Highly cost-effective; excellent $\text{IGC}$ resistance | Extreme corrosion/high $\text{T}$ resistance; superior thermal stability |

| Liner Thickness | Minimized for cost optimization ($\sim 2.5 \text{ mm}$ to $5 \text{ mm}$ typical) | Minimized for cost optimization ($\sim 2.0 \text{ mm}$ to $4 \text{ mm}$ typical) |

| Tolerance of Thickness | Governed by $\text{OD}$ of Outer Pipe, $\pm 0.75\%$ of $\text{OD}$ (Pipe standard) | Liner thickness controlled to $\pm 10\%$ of nominal liner thickness |

6. The Logistical Imperative: Field Welding, Joint Integrity, and the Challenge of Dissimilar Metal Joining

The transition of the bimetallic composite pipe from a high-performance material component to a fully realized operational piping system introduces a new, critical engineering challenge that must be addressed with the same metallurgical rigor applied to its manufacturing: the complexity of field welding and joint integrity. A composite pipe is only as effective as its weakest point, and that weakness is invariably the joint where the continuous corrosion barrier of the liner is interrupted. The installation process demands specialized procedures that simultaneously maintain the structural strength of the outer carbon steel layer, prevent sensitization or thermal damage to the inner alloy liner, and re-establish the chemical barrier across the joint interface, often requiring precise dissimilar metal welding techniques and the use of specialized transition components.

Re-establishing the Corrosion Barrier at the Joint

When a composite pipe is cut and prepared for joining, the highly resistant alloy liner is necessarily exposed at the end face. If the pipe sections were simply butt-welded together using a standard carbon steel procedure, the corrosive medium would gain direct access to the unprotected outer steel, leading to catastrophic failure of the entire system from the interior. Therefore, the joining process is a meticulously controlled two-stage operation.

First, the thick, load-bearing outer carbon steel shell is welded using conventional, high-strength welding procedures suitable for the base material (e.g., matching the $\text{A}106$ grade). This weld is the structural backbone, requiring the standard preheat and a precise Post-Weld Heat Treatment (PWHT) to relieve residual stresses and optimize the microstructure of the carbon steel weld metal and Heat Affected Zone (HAZ), conforming to codes like ASME B31.3. However, this required PWHT thermal cycle, typically in the range of $600^{\circ}\text{C}$ to $750^{\circ}\text{C}$, poses an immediate threat to the inner stainless steel liner, risking the sensitization and chromium carbide precipitation discussed earlier, even if an ultra-low carbon ($\text{L}$-grade) liner is used, as the prolonged heat exposure can still destabilize the material. The procedure must be precisely controlled to minimize the time spent in the sensitization range.

Second, and most critically, once the outer structural weld is complete and $\text{PWHT}$ is performed, the corrosion barrier must be meticulously re-established across the exposed joint face. This is accomplished by performing a specialized, internal overlay weld, utilizing filler metal that matches the composition of the inner liner (e.g., $316\text{L}$ filler for a $316\text{L}$ liner, or a $\text{NiCrMo}$ filler for a nickel alloy liner). This highly skilled weld must be applied over the exposed carbon steel of the joint and fused back onto the alloy liner, creating a continuous, protective weld bead that fully shields the outer steel from the process fluid. The technical complexity is compounded by the fact that this is a dissimilar metal weld (alloy filler to carbon steel base), demanding careful selection of buffer layers or compatible consumables to avoid the formation of brittle intermetallic phases that could crack under operational stress. The entire success of the composite system in the field hinges upon the precision and verified integrity of this final, internal, corrosion-sealing weld.

Specialized Transition Spools and Fittings

For complex piping routes involving elbows, tees, reducers, and flanges, the use of prefabricated composite fittings or transition pieces is often mandatory. The complex geometry of an elbow, for example, cannot reliably be lined in situ. Instead, Abtersteel fabricates these components using specialized internal cladding techniques or explosion-bonded bimetallic plates that are hydroformed. For connecting the composite pipe to existing equipment or specialized components (e.g., valves, pumps), custom-engineered transition spools are utilized. These spools feature a short section of solid alloy material on one end (matching the liner) that is welded to the equipment, and the bimetallic composite structure on the other end, allowing the field team to perform the easier, predictable structural weld to the outer carbon steel and the final alloy overlay, thereby simplifying the most complex joining points and ensuring the continuity of the corrosion barrier without compromise. The sophisticated engineering involved in manufacturing these fittings is crucial for making the bimetallic piping system logistically viable for large-scale industrial projects.

7. The Life-Cycle Economics of Dual Metallurgy: Beyond Initial Capital Cost

While the initial cost savings—$1/3$ for stainless steel lined and $1/6$ for nickel-alloy lined systems—are the immediate and most compelling commercial driver for adopting Abtersteel’s composite pipe, the true economic superiority of the dual metallurgy approach is fully appreciated only through a comprehensive Life-Cycle Cost (LCC) analysis. LCC modeling moves beyond the simple procurement price (CAPEX) to incorporate long-term operational costs (OPEX), maintenance, downtime, and replacement cycles over the project’s 20-to-30-year expected service life.

Decoupling Corrosion from Structural Life

The primary economic failing of traditional piping materials in corrosive service is the coupling of their corrosion resistance to their structural integrity. When a solid stainless steel pipe corrodes, the structural wall thickness is immediately reduced, directly compromising its pressure containment rating and forcing early replacement. Similarly, when non-metallic liners (like $\text{FRP}$ or $\text{PTFE}$ coatings) fail due to abrasive wear, thermal stress cracking, or localized chemical attack, the underlying steel substrate is exposed, leading to rapid, catastrophic corrosion that necessitates immediate and costly shutdown and replacement.

The bimetallic composite pipe fundamentally decouples the two failure modes. The structural integrity is based on the thick, robust carbon steel, which is fully shielded from the corrosive environment. The corrosion barrier, the thin liner, is protected from external mechanical loads. Failure of the liner is a highly improbable event given its metallurgical bonding and superior chemical resistance, but even if minor localized penetration were to occur, the failure is localized and slow. The predicted structural life of the pipe is thus determined almost entirely by the outer steel’s resistance to external factors (e.g., atmospheric corrosion), rather than the internal process fluid, dramatically extending the component’s usable life. This extended, predictable service life reduces the required Discounted Cash Flow (DCF) for future replacement by decades.

Quantifying the Cost of Downtime and Maintenance

In the petrochemical and power industries, the cost of unplanned downtime often dwarfs the initial material cost of the component that failed. A single day of shutdown in a large refinery or chemical plant can result in millions of dollars in lost production revenue. Solid alloy piping, while resistant, eventually succumbs to creep, thermal fatigue, or localized erosion, requiring scheduled outages for inspection and replacement. Non-metallic liners, due to their inherent susceptibility to temperature spikes and mechanical impact, are frequent culprits in unscheduled downtime events. The composite pipe, with its superior structural stability and the extreme corrosion and thermal fatigue resistance of the metallurgically bonded inner liner (especially the thermal compatibility of the nickel alloy), significantly minimizes both scheduled and unscheduled maintenance cycles related to internal corrosion or material degradation.

LCC models consistently show that while the initial capital expenditure for the composite pipe is higher than for carbon steel, the total ownership cost over 25 years is dramatically lower than that of both solid alloy pipe and non-metallics, affirming the dual-metallurgy approach as the most financially responsible long-term solution for aggressive fluid transfer.

8. Future Trajectories and the Standardization Imperative for Bimetallic Composites

The successful commercialization of the stainless steel and nickel-based alloy lined pipes by Abtersteel is not the conclusion of the development cycle, but rather a significant milestone that points toward a promising and essential future trajectory for high-performance piping materials globally. Continued research and development are focused on pushing the envelope of both the liner materials and the manufacturing process itself.

Pushing the Limits: Exotic Liners and Higher Pressure Ratings

The next generation of composite piping technology is already being explored, focusing on even more exotic liners that address highly specific, niche corrosive environments not adequately handled by stainless steel or the standard $\text{NiCrMoFe}$ alloys. This includes research into Titanium-lined composite pipes, essential for processes involving wet chlorine and oxidizing chlorides, and potentially Zirconium-lined pipes, which offer exceptional resistance to reducing acids at high concentrations. The challenge here is less about the bonding mechanism and more about managing the significant differences in thermal expansion coefficients and metallurgical compatibility between these refractory metals and carbon steel. Success in these areas will unlock the use of these exotic materials in applications currently limited to small-bore solid piping due to cost.

Furthermore, there is a continuous drive to increase the operational pressure and temperature ratings, which requires the outer carbon steel jacket to be upgraded to higher-strength, low-alloy steels (like $\text{A}335 \text{ P}91$ or $\text{P}92$) and the bonding interface to withstand greater shear stresses and thermal fluctuations. This requires refinement of the SHS or explosive bonding parameters to ensure bond integrity under $3000+\text{ psi}$ service pressures.

The Critical Need for Global Standardization

While Abtersteel and other advanced manufacturers adhere to rigorous internal quality standards, the widespread, confident adoption of metallurgically bonded bimetallic composite piping on a global scale is still constrained by the current lack of a universally accepted, dedicated international design code. Currently, engineers must rely on fragmented standards, often referencing the welding requirements of ASME Boiler and Pressure Vessel Code Section IX and the pressure design requirements of ASME B31.3 (Process Piping), while applying the cladding quality checks found in ASTM A263/A264 (for clad plates).

The future growth of this technology depends on international bodies like $\text{ISO}$ and $\text{ASME}$ establishing a comprehensive, unified standard specifically for metallurgically bonded composite piping. Such a standard would define clear requirements for bond shear strength minimums, permissible non-bond areas verified by UT, acceptable PWHT procedures to prevent sensitization in $\text{L}$-grade liners, and the design rules for complex composite fittings. Achieving this standardization will eliminate design uncertainty, accelerate regulatory acceptance, and allow engineers globally to integrate the superior LCC benefits of the bimetallic composite pipe into their most critical infrastructure projects, confirming its status as the indispensable material solution for the future of corrosive fluid handling.