Incoloy 901 Nickel Alloy Steel Pipe (UNS N09901/DIN 1.4898)

July 30, 2025

Hastelloy X UNS N06002 – W. Nr. 2.4665 | Sheet/Bar/Pipe/ Plate/Foring Ring

August 10, 2025

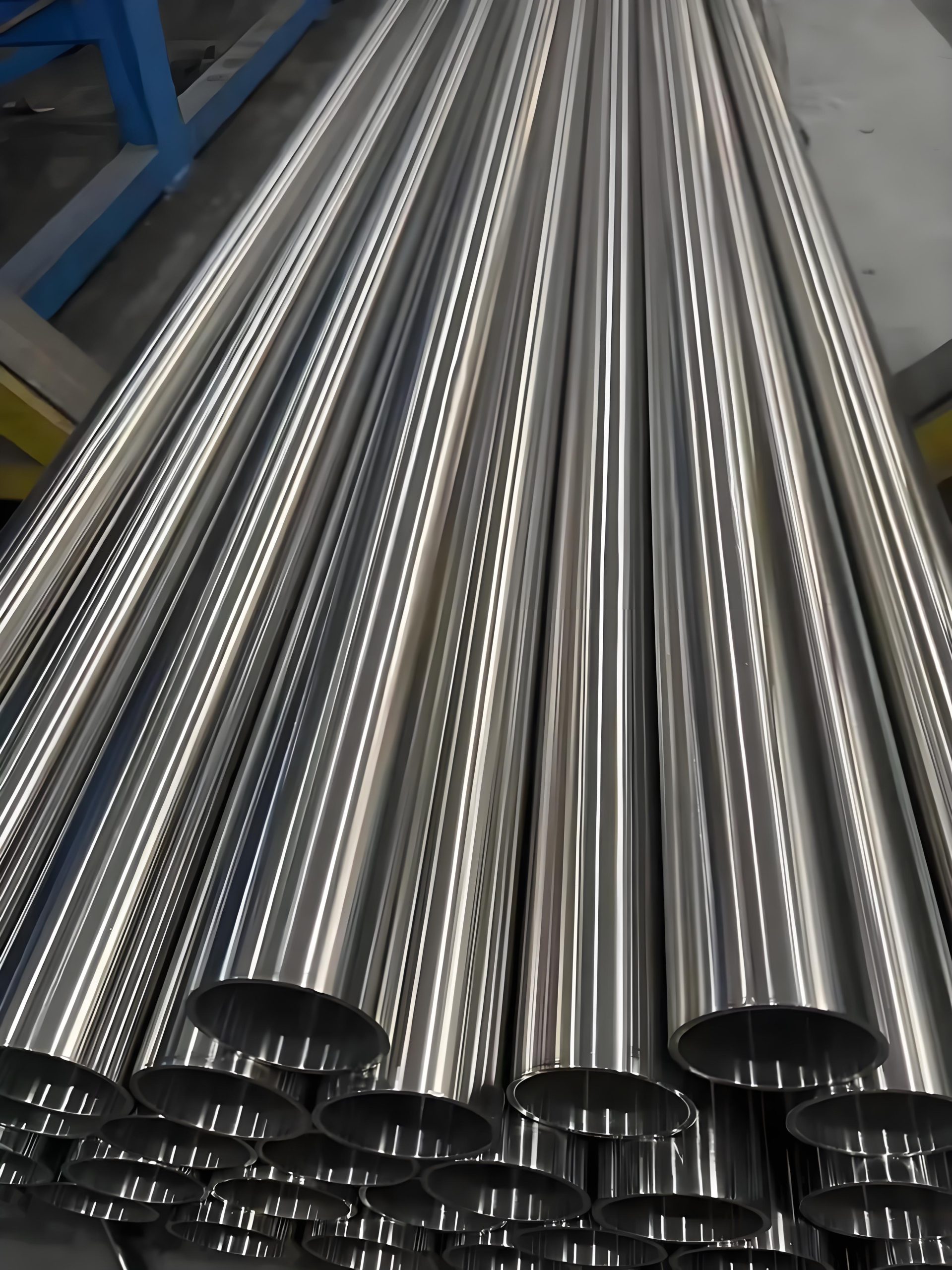

Nickel Alloy 718 (Inconel® 718, UNS N07718, W. Nr. 2.4668) Steel Pipe

Introduction to Inconel® 718

Nickel Alloy 718, commonly known as Inconel® 718 (UNS N07718, W. Nr. 2.4668), is a high-performance nickel-chromium superalloy renowned for its exceptional strength, corrosion resistance, and versatility in extreme environments. Developed for demanding applications in aerospace, oil and gas, and power generation, Inconel 718 is particularly valued for its ability to maintain mechanical properties at temperatures ranging from cryogenic levels to 1300°F (704°C). Its unique combination of high yield strength, fatigue resistance, and oxidation resistance makes it a preferred material for seamless and welded pipes used in critical systems like jet engines, gas turbines, and high-pressure fluid transport.

The alloy’s composition, featuring nickel, chromium, molybdenum, niobium, titanium, and aluminum, is engineered to provide a balance of strength, toughness, and corrosion resistance. Niobium and titanium contribute to precipitation hardening through the formation of γ’ and γ” phases, while molybdenum enhances creep resistance and corrosion resistance in aggressive media. Inconel 718 pipes are widely used in applications requiring durability under thermal cycling, high-pressure conditions, and corrosive environments, such as sour gas wells and chemical processing plants. This article provides a detailed exploration of Inconel 718 steel pipes, covering their chemical composition, mechanical properties, corrosion resistance, manufacturing processes, and applications. Comprehensive tables summarize key parameters, offering a valuable reference for engineers and manufacturers. By examining its characteristics and comparing it to other alloys like Incoloy 901, this article underscores Inconel 718’s significance in modern engineering.3

Chemical Composition and Material Analysis

Inconel 718 is an austenitic nickel-based superalloy with a carefully balanced chemical composition that underpins its exceptional performance. The typical composition, expressed as weight percentages, includes 50.0–55.0% nickel, 17.0–21.0% chromium, 4.75–5.50% niobium, 2.8–3.3% molybdenum, 0.65–1.15% titanium, 0.2–0.8% aluminum, and a balance of iron (approximately 18–20%), with trace amounts of carbon (≤0.08%), manganese (≤0.35%), silicon (≤0.35%), phosphorus (≤0.015%), sulfur (≤0.015%), and boron (≤0.006%). These elements are meticulously controlled to optimize strength, corrosion resistance, and weldability.

Nickel provides the foundation for high-temperature stability and corrosion resistance, enabling Inconel 718 to withstand aggressive environments like jet engine exhausts and sour gas wells. Chromium forms a protective oxide layer, enhancing oxidation resistance up to 1300°F (704°C). Niobium, combined with titanium and aluminum, drives the formation of γ’ [Ni3(Al, Ti)] and γ” [Ni3Nb] phases during aging, significantly increasing yield strength through precipitation hardening. Molybdenum enhances resistance to pitting and crevice corrosion, particularly in chloride-rich environments, while also contributing to solid-solution strengthening. The low carbon content minimizes carbide precipitation, reducing the risk of sensitization during welding, and boron strengthens grain boundaries, improving creep resistance.

The alloy’s microstructure remains stable across a wide temperature range, resisting phase transformations that could degrade performance. Compared to Incoloy 901 (40–45% nickel, 2.35–3.10% titanium), Inconel 718 has a higher nickel and niobium content, enhancing its strength and corrosion resistance but increasing manufacturing complexity. This composition makes Inconel 718 pipes ideal for applications requiring durability in extreme conditions, meeting standards like AMS 5589 and ASTM B983 for seamless nickel alloy tubing.

Mechanical Properties of Inconel 718 Pipes

The mechanical properties of Inconel 718 pipes are a hallmark of their suitability for high-stress applications. At room temperature, the alloy exhibits a minimum yield strength of approximately 1035 MPa (150 ksi) and a tensile strength of 1275 MPa (185 ksi), with an elongation of 12–15%. These properties are maintained up to 1300°F (704°C), with a yield strength of around 860 MPa (125 ksi) at 1200°F (649°C), making it ideal for high-temperature environments. The alloy’s creep rupture strength is exceptional, withstanding prolonged stress at elevated temperatures, a critical factor for gas turbine components and high-pressure piping.

Precipitation hardening, driven by γ’ and γ” phases, is responsible for Inconel 718’s high strength. The aging process, typically conducted at 1325–1475°F (718–802°C), optimizes these phases, enhancing resistance to creep and fatigue. The alloy’s fatigue resistance is particularly valuable in cyclic loading conditions, such as those in aerospace propulsion systems, where Inconel 718 pipes endure thermal and mechanical stresses without degradation. Its toughness and ductility allow for forming into seamless pipes through hot working at 1850–2100°F (1010–1150°C), with cold working possible for smaller diameters.

Compared to Incoloy 901 (yield strength ~900 MPa), Inconel 718 offers superior strength and creep resistance, though it is more challenging to forge due to its higher nickel content. Heat treatments, such as solution annealing at 1900–1950°F (1038–1066°C) followed by aging, ensure optimal microstructure stability. These properties make Inconel 718 pipes a reliable choice for demanding applications, from turbine casings to high-pressure oil and gas pipelines.

Corrosion Resistance Characteristics

Inconel 718 is engineered for superior corrosion resistance, particularly in harsh environments encountered in aerospace, oil and gas, and chemical processing industries. Its high nickel (50–55%) and chromium (17–21%) content forms a robust oxide layer, providing excellent resistance to oxidation and scaling at temperatures up to 1300°F (704°C). The alloy excels in jet engine atmospheres, resisting sulfur-containing gases and high-temperature oxidation. Molybdenum (2.8–3.3%) enhances resistance to pitting and crevice corrosion in chloride-rich environments, such as seawater or sour gas wells, making Inconel 718 pipes suitable for offshore applications.

The alloy’s resistance to stress-corrosion cracking (SCC) is a key advantage, particularly in high-pressure systems where tensile stresses and corrosive media coexist. Its low carbon content and controlled heat treatments minimize sensitization, reducing intergranular corrosion during prolonged exposure to elevated temperatures. Inconel 718 outperforms Incoloy 901 in highly oxidizing environments, such as those involving nitric acid, due to its higher nickel and niobium content, though it is slightly less resistant to scaling than stainless steels like Types 309 and 310 at extreme temperatures.

In marine environments, Inconel 718’s pitting resistance, bolstered by molybdenum, ensures long-term durability, though protective coatings may be applied for extended service life. The alloy’s stability in reducing environments, such as hydrogen sulfide in oil and gas wells, further enhances its versatility. These corrosion-resistant properties make Inconel 718 pipes a preferred choice for applications requiring reliability in aggressive chemical and thermal conditions, ensuring structural integrity and safety.

Manufacturing and Processing of Inconel 718 Pipes

The production of Inconel 718 pipes involves advanced metallurgical and manufacturing processes to achieve the desired properties. The alloy is typically hot worked between 1850°F and 2100°F (1010°C–1150°C) to ensure formability without compromising the microstructure. Rapid heating through the precipitation hardening range is critical to prevent undesirable phase transformations. Seamless pipes are produced via extrusion or rotary piercing, followed by solution annealing at 1900–1950°F (1038–1066°C) and rapid cooling to dissolve precipitates. Aging at 1325–1475°F (718–802°C) promotes the formation of γ’ and γ” phases, maximizing strength and creep resistance.

Welded pipes are more challenging due to Inconel 718’s susceptibility to hot cracking, requiring techniques like gas tungsten arc welding (GTAW) in the solution-treated condition. Post-weld heat treatments restore properties, minimizing residual stresses. The alloy’s high nickel content makes forging more difficult than Incoloy 901, but its excellent toughness allows for precise forming into pipes with consistent wall thickness. Cold working is feasible for smaller diameters, followed by re-solution treatment to restore ductility before welding.

Inconel 718 pipes meet stringent standards, such as AMS 5589 for seamless tubing and ASTM B983 for high-pressure applications, ensuring compliance with industry requirements. Manufacturers like Special Metals and Sandvik employ advanced quality control to achieve precise dimensions and surface finishes, critical for high-performance systems. These processes ensure that Inconel 718 pipes deliver reliability in demanding environments, from aerospace to oil and gas extraction.

Applications of Inconel 718 Pipes

Inconel 718 pipes are integral to industries requiring materials that withstand extreme temperatures, pressures, and corrosive environments. In aerospace, they are used in jet engine components, such as turbine casings, exhaust systems, and fuel lines, where their high strength and oxidation resistance at temperatures up to 1300°F (704°C) ensure reliability. The alloy’s fatigue resistance is critical for components subjected to cyclic loading, such as compressor piping in gas turbines.

In the oil and gas industry, Inconel 718 pipes are employed in downhole tubing and high-pressure pipelines for sour gas wells, where resistance to hydrogen sulfide and chloride-induced corrosion is essential. Their creep resistance makes them suitable for high-temperature steam lines in power generation, while their cryogenic performance supports applications in liquefied natural gas (LNG) systems. Chemical processing plants use Inconel 718 pipes for transporting aggressive fluids, such as acids and alkalis, due to their pitting and SCC resistance.

Other applications include nuclear reactors, where the alloy’s stability in high-radiation environments is valuable, and marine systems, where it withstands seawater corrosion. The versatility of seamless and welded Inconel 718 pipes, available in various diameters and wall thicknesses, allows customization for specific project needs. Their ability to perform in extreme conditions ensures safety and efficiency, making them a cornerstone of advanced engineering applications.

Technical Specifications and Parameter Table

The following table summarizes the key parameters of Inconel 718 pipes, including chemical composition, mechanical properties, and physical characteristics, providing a clear reference for engineers.

| Parameter | Specification |

|---|---|

| Alloy Designation | Inconel® 718 (UNS N07718, W. Nr. 2.4668) |

| Chemical Composition | Ni: 50.0–55.0%, Cr: 17.0–21.0%, Nb: 4.75–5.50%, Mo: 2.8–3.3%, Ti: 0.65–1.15%, Al: 0.2–0.8%, Fe: Balance, C: ≤0.08%, Mn: ≤0.35%, Si: ≤0.35%, P: ≤0.015%, S: ≤0.015%, B: ≤0.006% |

| Density | 8.19 g/cm³ (0.296 lb/in³) |

| Tensile Strength (Room Temp) | ≥1275 MPa (185 ksi) |

| Yield Strength (Room Temp) | ≥1035 MPa (150 ksi) |

| Elongation (Room Temp) | 12–15% |

| Creep Rupture Strength | High at 1300°F (704°C), specific values depend on heat treatment |

| Corrosion Resistance | Excellent in jet engine atmospheres, resistant to pitting, crevice corrosion, and SCC |

| Oxidation Resistance | Effective up to 1300°F (704°C) |

| Hot Working Temperature | 1850–2100°F (1010–1150°C) |

| Heat Treatment | Solution annealing at 1900–1950°F (1038–1066°C), aging at 1325–1475°F (718–802°C) |

| Weldability | Moderate, requires GTAW in solution-treated condition |

| Standards | AMS 5589, ASTM B983, ASME SB163, ISO 6207 |

| Applications | Jet engine components, oil and gas pipelines, chemical processing, nuclear reactors |

This table serves as a quick reference for the alloy’s capabilities, ensuring designers can select Inconel 718 pipes for specific performance requirements.

Comparison with Incoloy 901 and Pipe Piling Grades

Inconel 718 is often compared to Incoloy 901 and pipe piling grades (EN10219-1, API 5L) due to their overlapping applications in high-performance and structural contexts. Incoloy 901 (UNS N09901), with a yield strength of ~900 MPa and tensile strength of 1150 MPa, is slightly less robust than Inconel 718 (1035 MPa yield, 1275 MPa tensile). Inconel 718’s higher nickel (50–55% vs. 40–45%) and niobium (4.75–5.50%) content enhance its strength and corrosion resistance, particularly in oxidizing acids and high-temperature environments. However, Incoloy 901’s higher iron content improves forgeability, making it easier to manufacture into pipes.

Compared to pipe piling grades like EN10219-1 S355JOH (yield strength 355 N/mm²) or API 5L X52 (360 N/mm²), Inconel 718 offers significantly higher strength and corrosion resistance but at a much higher cost. Pipe piling grades are optimized for structural applications like deep foundations, with carbon contents up to 0.26% and manganese up to 1.65%, providing adequate strength and weldability for general construction. Inconel 718, with its nickel-based composition, is reserved for extreme conditions, such as sour gas pipelines or aerospace systems, where carbon steels would fail due to corrosion or temperature limitations.

The choice between Inconel 718, Incoloy 901, and pipe piling grades depends on project requirements. Inconel 718 excels in high-temperature, corrosive environments, while Incoloy 901 offers a cost-effective alternative for slightly less demanding conditions, and pipe piling grades are ideal for structural applications with lower environmental challenges.

Challenges and Limitations

Despite its superior properties, Inconel 718 has limitations that require careful consideration. Weldability is a primary challenge, as the alloy is prone to hot cracking during welding due to its high nickel and niobium content. Gas tungsten arc welding (GTAW) in the solution-treated condition, followed by post-weld heat treatment, is necessary to minimize cracking, increasing production complexity and cost. Compared to Incoloy 901, which is also difficult to weld but less so due to its higher iron content, Inconel 718 requires more stringent controls.

The alloy’s high cost, driven by its nickel and niobium content, limits its use to applications where performance justifies the expense. For general structural applications, pipe piling grades like API 5L X70 (yield strength 485 N/mm²) are more economical, offering sufficient strength for foundations but lacking Inconel 718’s corrosion resistance. At temperatures above 1300°F (704°C), Inconel 718’s strength and oxidation resistance decline, requiring alternative alloys like Inconel 625 for extreme conditions. Cold working is also challenging due to the alloy’s high strength, necessitating precise control to avoid defects.

Corrosion resistance, while excellent, is not universal; Inconel 718 is less effective in highly oxidizing acids like nitric acid compared to Inconel 625. Engineers must assess environmental conditions and apply coatings or cathodic protection in marine settings to extend service life. By addressing these challenges through optimized manufacturing and design, Inconel 718 pipes can deliver exceptional performance in critical applications.

Future Trends and Innovations

The demand for Inconel 718 pipes is expected to grow as industries like aerospace, oil and gas, and renewable energy push the boundaries of material performance. Advances in additive manufacturing are enabling the production of complex pipe geometries, improving efficiency and reducing material waste. Research into optimized heat treatments is enhancing the alloy’s creep and fatigue resistance, extending service life in high-temperature applications like next-generation gas turbines. Innovations in welding techniques, such as laser welding, are addressing Inconel 718’s weldability challenges, reducing cracking risks and production costs.

Emerging applications in renewable energy, such as geothermal and concentrated solar power systems, are driving demand for Inconel 718 pipes due to their ability to withstand high temperatures and corrosive fluids. The alloy’s cryogenic performance is also gaining attention in LNG and aerospace applications, where low-temperature toughness is critical. Sustainability is a key focus, with manufacturers exploring recycled nickel and energy-efficient processing to reduce environmental impact. Digital tools, such as real-time monitoring of pipe performance, are improving design and maintenance, ensuring optimal use in extreme conditions.

Collaborations between industry leaders like Special Metals and research institutions are driving the development of next-generation nickel alloys, potentially enhancing Inconel 718’s properties further. As industries demand higher efficiency and durability, Inconel 718 pipes will remain a vital material, supporting innovation in critical engineering applications.

Inconel 718 (UNS N07718, W. Nr. 2.4668) steel pipes represent a pinnacle of materials engineering, offering unmatched strength, corrosion resistance, and versatility for extreme environments. With a yield strength exceeding 1035 MPa and excellent performance up to 1300°F (704°C), the alloy is ideal for aerospace, oil and gas, and chemical processing applications. Its chemical composition, rich in nickel, chromium, and niobium, ensures robust corrosion resistance, while precipitation hardening enhances mechanical properties. Manufacturing processes, though complex, produce reliable seamless and welded pipes meeting standards like AMS 5589 and ASTM B983.

Compared to Incoloy 901 and pipe piling grades (EN10219-1, API 5L), Inconel 718 offers superior strength and corrosion resistance but at a higher cost, making it suitable for specialized applications rather than general structural use. Challenges like weldability and cost are being addressed through innovative manufacturing and sustainable practices. The detailed parameter table provided in this article serves as a valuable resource for selecting Inconel 718 pipes, guiding engineers in optimizing performance. As industries evolve, Inconel 718 will continue to play a critical role, ensuring safety, efficiency, and durability in the most demanding engineering challenges.