Nickel Alloy 718 (Inconel® 718, UNS N07718, W. Nr. 2.4668) Steel Pipe

August 8, 2025

ASTM A672 EFW Steel Pipe | GR C60 B60 C65 C70

August 18, 2025Hastelloy X UNS N06002 – W. Nr. 2.4665: Material Overview and Properties

Introduction to Hastelloy X UNS N06002

Hastelloy X UNS N06002, a high-performance nickel-based alloy, is designed to offer superior resistance to oxidation, carburization, and other forms of deterioration in extreme environments. Composed mainly of nickel (Ni), chromium (Cr), molybdenum (Mo), and iron (Fe), this material is highly regarded for its ability to maintain strength and resilience even at temperatures that exceed 1000°F (537°C). It was originally developed for use in gas turbines, aerospace applications, and chemical processing, where high temperature and corrosion resistance are of paramount importance. The outstanding properties of Hastelloy X make it a top contender for critical components such as turbine blades, combustion chambers, heat exchangers, and nuclear reactors. This unique composition ensures that Hastelloy X maintains its structural integrity even under the harshest conditions, including exposure to high-pressure gases, hot liquids, and chemicals, which would typically degrade other materials.

The versatility and reliability of Hastelloy X in these demanding applications have led to its widespread use across several high-tech industries. In aerospace, it is particularly favored for engine components that experience extreme thermal and mechanical stresses. The material’s resistance to oxidation allows it to operate effectively at elevated temperatures, a critical requirement for components subjected to the intense heat generated by gas turbines during flight. Similarly, in the chemical processing industry, Hastelloy X is used for valves, reactors, and heat exchangers, where it can withstand high-pressure corrosive environments without compromising safety or performance. The long-term reliability of Hastelloy X is one of the main reasons why it has been adopted in such industries, offering manufacturers confidence in its performance over extended periods of use in high-stress environments.

Product Description

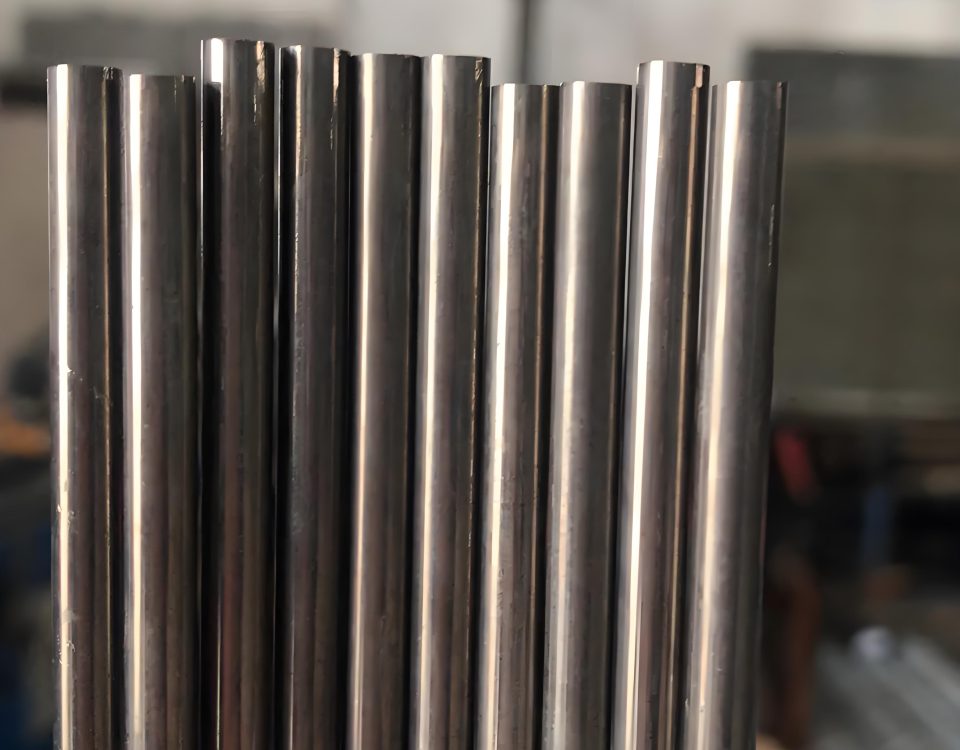

Hastelloy X is available in a variety of product forms to suit a wide range of manufacturing needs. These include sheets, bars, pipes, plates, and forging rings. Each of these forms offers specific advantages depending on the application, and the material can be easily processed into various shapes and sizes to meet particular requirements. In sheet form, Hastelloy X is commonly used for the production of flat components, such as heat exchangers or sealing components, that need to resist oxidation and corrosion in high-temperature environments. The material’s ease of fabrication and strong mechanical properties make it an ideal choice for such applications.

In bar and pipe form, Hastelloy X is used extensively for structural and fluid-handling components. Its high strength and resistance to chemical attack make it suitable for use in power plants and chemical processing systems where the material will be exposed to both high temperatures and corrosive fluids. For example, Hastelloy X pipes are used in industries that process chemicals, such as petroleum refining, where they resist cracking and erosion caused by aggressive substances. Plates of Hastelloy X are often used when large, flat components are needed, especially in industries like aerospace and energy production, where large structural elements are exposed to extreme thermal conditions.

Forging rings, a specialized product form of Hastelloy X, are often used in the manufacture of turbine blades, seals, and other components that require excellent resistance to creep and thermal fatigue. These components must maintain their strength and shape even when subjected to the extreme conditions found in gas turbines or power generation units. The forging process helps enhance the material’s mechanical properties by improving its grain structure, making it stronger and more resistant to thermal stress. Whether used for the aerospace, chemical, or power generation industries, each form of Hastelloy X offers unique benefits that make it the material of choice for high-temperature and high-pressure applications.

Mechanical Properties

Hastelloy X exhibits a range of outstanding mechanical properties that make it well-suited for applications in extreme environments. One of its most impressive characteristics is its ability to maintain high tensile and yield strengths even at elevated temperatures. Typically, Hastelloy X has a tensile strength of around 100,000 psi (690 MPa) and a yield strength of about 40,000 psi (276 MPa). These values ensure that the material is capable of withstanding significant mechanical stresses without permanent deformation. It is also highly resistant to creep, which is the tendency of a material to slowly deform under constant stress at high temperatures. This resistance to creep allows Hastelloy X to perform reliably in long-term applications where it is subjected to constant pressure and elevated temperatures, such as in turbine blades or heat exchangers.

In addition to its strength, Hastelloy X also maintains excellent elongation properties. With an elongation of about 35%, the material can undergo significant deformation before breaking, making it well-suited for applications where complex shapes need to be formed without compromising the material’s integrity. This ductility is an essential characteristic for parts that are subjected to thermal and mechanical stresses, as it allows for the necessary movement without fracture. The material also boasts impressive hardness, with a Rockwell B hardness rating of approximately 85, indicating its resistance to wear and abrasion. This property is particularly valuable in industries where mechanical components experience high levels of friction, as it helps maintain the structural integrity of the part over time.

Thermal stability is another defining mechanical property of Hastelloy X. Unlike many alloys that suffer from reduced strength at high temperatures, Hastelloy X maintains its performance at temperatures up to around 2000°F (1093°C), making it ideal for high-temperature applications such as gas turbines and heat exchangers. The material’s ability to withstand both oxidative and carburizing conditions at these elevated temperatures is due to the alloy’s carefully engineered composition, which includes high levels of chromium and molybdenum. These elements form a protective oxide layer on the material’s surface that helps prevent degradation, ensuring long-lasting performance even under severe conditions. Overall, the combination of high strength, excellent thermal stability, and impressive ductility makes Hastelloy X one of the most reliable materials for extreme applications in the aerospace, chemical processing, and power generation industries.

Common Specifications

Hastelloy X is manufactured to meet several industry standards and specifications that ensure the material is capable of performing in the harshest environments. These specifications cover a range of characteristics, including the material’s mechanical properties, chemical composition, and fabrication methods. Among the most common specifications for Hastelloy X are ASTM B834, ASME SB-834, and DIN 17745. Each of these standards sets the requirements for various forms of the material, ensuring that it meets the necessary performance criteria for specific applications.

ASTM B834 is the standard specification for Hastelloy X in the form of bars, plates, sheets, and forgings. This specification outlines the mechanical properties, chemical composition, and dimensional tolerances that must be met during the manufacturing process. It provides guidelines for the fabrication of Hastelloy X components that are used in high-temperature and high-pressure environments, ensuring that the material is capable of withstanding the harsh conditions typically found in the aerospace, chemical, and energy industries. The ASME SB-834 specification is similar to ASTM B834, but it applies specifically to Hastelloy X used in pressure vessels, heat exchangers, and other components in the power and chemical industries. This standard is especially important for ensuring the safety and reliability of components that will be exposed to both high temperatures and high pressures over extended periods.

DIN 17745 is a German standard that applies to Hastelloy X used in high-temperature applications. This standard ensures that the material meets specific mechanical properties and corrosion resistance requirements that are necessary for applications in the chemical, energy, and aerospace industries. Adhering to these specifications guarantees that Hastelloy X components will perform as expected, providing long-term reliability in demanding applications. Manufacturers that produce Hastelloy X components typically test their materials against these standards to ensure quality control, and compliance with these specifications is essential for ensuring that the material will meet the performance requirements for its intended use. As such, Hastelloy X is a material that is trusted by engineers and manufacturers for its durability, versatility, and performance in extreme environments.

Chemistry Nominal Composition

The chemistry of Hastelloy X plays a crucial role in determining its overall properties, including its resistance to high temperatures, oxidation, and carburization. The nominal composition of Hastelloy X consists primarily of nickel (Ni), chromium (Cr), molybdenum (Mo), and iron (Fe), with smaller amounts of cobalt (Co), manganese (Mn), silicon (Si), and copper (Cu). The high nickel content, which ranges from 47.5% to 50.5%, forms the base of the alloy and provides the material with its excellent corrosion resistance and thermal stability. Nickel is known for its ability to resist oxidation and other forms of degradation at elevated temperatures, making it an essential component of Hastelloy X.

Chromium, which constitutes between 20% and 23% of the alloy, plays a key role in enhancing the material’s oxidation resistance. When exposed to high temperatures, chromium forms a protective oxide layer on the surface of the material, preventing further degradation and extending the lifespan of the component. Molybdenum, at 8% to 10%, contributes to the alloy’s resistance to carburization, which is a form of chemical degradation that occurs when carbon-rich gases react with metal surfaces. Molybdenum also enhances the material’s strength and creep resistance at elevated temperatures. Iron, which makes up around 15% to 17% of the alloy, provides the material with additional strength and hardness while maintaining its ability to resist corrosion.

Other trace elements, such as cobalt, manganese, and silicon, further enhance the material’s properties. Cobalt improves the overall strength and heat resistance of the alloy, while manganese helps improve the material’s toughness and resistance to corrosion in acidic environments. Silicon, present in small amounts, helps improve the alloy’s resistance to oxidation and promotes better casting properties. Finally, copper, present in minute quantities, adds to the material’s overall corrosion resistance, particularly in chloride environments. Together, these elements combine to give Hastelloy X its outstanding performance characteristics, making it an ideal choice for applications in high-temperature and corrosive environments.

Applications and Use Cases

Hastelloy X is used in a wide range of applications across various industries, including aerospace, chemical processing, power generation, and more. Its ability to resist oxidation, carburization, and high-temperature degradation makes it a go-to material for components that operate under extreme conditions. In the aerospace industry, Hastelloy X is used to fabricate critical components such as turbine blades, combustion chambers, and heat exchangers. These components are exposed to temperatures that can reach well over 1000°F (537°C) during operation, and the material’s ability to maintain its strength and resistance to thermal and mechanical stress is essential for ensuring the performance and safety of aircraft engines.

In the chemical processing industry, Hastelloy X is used for equipment such as valves, reactors, and heat exchangers. These components must be able to withstand the harsh conditions found in chemical processing environments, where high temperatures and corrosive substances are prevalent. Hastelloy X’s excellent resistance to corrosion and high-temperature stability make it an ideal choice for such applications. In power generation, Hastelloy X is used to manufacture parts for gas turbines, nuclear reactors, and heat exchangers. The material’s ability to resist high-pressure steam and corrosive gases, along with its excellent thermal stability, ensures the longevity and reliability of power plant components.

Advantages of Using Hastelloy X

There are several advantages to using Hastelloy X in high-temperature and high-stress applications. One of the key benefits is its exceptional resistance to oxidation, which allows it to maintain its integrity even when exposed to extremely hot, oxygen-rich environments. This property makes it ideal for use in applications like gas turbines and aerospace components, where prolonged exposure to high temperatures is inevitable. Additionally, Hastelloy X’s resistance to carburization makes it suitable for use in environments where carbon-containing gases are present. This resistance to carburization helps protect the material from degradation, ensuring its longevity and reliability in demanding environments.

Another significant advantage of Hastelloy X is its excellent creep resistance. Creep is the gradual deformation of materials under constant stress at elevated temperatures, and it can be a major concern in components like turbine blades that experience continuous mechanical stress. Hastelloy X’s resistance to creep ensures that components made from the material retain their shape and strength over extended periods of operation, even in high-stress, high-temperature environments. The alloy’s superior strength and mechanical properties, combined with its excellent thermal stability, make it an ideal choice for manufacturers seeking reliable, long-lasting materials for extreme applications.

Product Performance and Testing

Ensuring the performance and reliability of Hastelloy X requires rigorous testing and quality assurance procedures. Manufacturers typically conduct a range of tests to verify the material’s mechanical properties, including tensile strength, yield strength, elongation, and hardness. These tests help ensure that the material can withstand the mechanical stresses that are typically encountered in high-temperature applications. In addition to mechanical testing, Hastelloy X is often subjected to environmental testing to assess its resistance to oxidation, carburization, and corrosion. These tests simulate the harsh conditions that the material will face in real-world applications, ensuring that it will perform as expected when exposed to high temperatures, corrosive gases, and other aggressive substances.

Hastelloy X is also subjected to non-destructive testing (NDT) methods, such as ultrasonic testing, radiographic inspection, and visual inspection, to detect any internal flaws or surface defects that could affect the material’s performance. These tests are crucial for ensuring the safety and reliability of components made from Hastelloy X, particularly in industries where the material will be used in critical applications, such as aerospace or nuclear power. By following strict quality control procedures and testing standards, manufacturers can ensure that Hastelloy X will perform as expected and meet the stringent requirements of high-performance industries.

Conclusion

Hastelloy X UNS N06002 (W. Nr. 2.4665) is a premium nickel-based alloy that offers outstanding performance in high-temperature and corrosive environments. Its remarkable resistance to oxidation, carburization, and high-temperature degradation makes it an invaluable material for industries such as aerospace, chemical processing, and power generation. With its excellent mechanical properties, including high tensile strength, creep resistance, and thermal stability, Hastelloy X is a material of choice for critical applications where reliability and durability are essential. By adhering to industry standards and ensuring rigorous testing, manufacturers can ensure that Hastelloy X components will perform effectively and consistently, offering long-term performance in even the most demanding environments.