ASTM A268 TP410 Boiler Tubing

August 24, 2024

ASTM B619 UNS N06022 Hastelloy C22 Pipe

August 31, 2024Hastelloy C22 N06022 2.4602 NiCr21Mo14W Nickel-Based Alloy Pipe

Introduction

In industries where extreme conditions are the norm, materials that can withstand high temperatures, corrosive environments, and mechanical stress are essential. Hastelloy C22, known by its UNS number N06022 and Werkstoff number 2.4602, is a nickel-based alloy that excels in such demanding applications. This article explores the characteristics, applications, and benefits of Hastelloy C22 pipes, highlighting their role in enhancing the performance and reliability of industrial systems.

Understanding Hastelloy C22

What is Hastelloy C22?

Hastelloy C22 is a nickel-chromium-molybdenum-tungsten alloy known for its exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking. Its unique composition, including elements like chromium, molybdenum, and tungsten, provides outstanding protection in both oxidizing and reducing environments.

Key Properties of Hastelloy C22

- Corrosion Resistance: Offers superior resistance to a wide range of corrosive chemicals, including chlorides, acids, and seawater.

- High-Temperature Performance: Maintains its mechanical properties and corrosion resistance at elevated temperatures, making it ideal for high-temperature applications.

- Versatility: Suitable for a variety of applications due to its excellent resistance to multiple forms of corrosion.

Characteristics of Hastelloy C22 Pipes

Specifications

Hastelloy C-22 is covered by ASME . Plate, sheet, strip, bar, tubing, and pipe are covered by ASME specifications SB-574, SB-575, SB-619, SB-622 and SB-626 and by ASTM specifications B-574, B-575, B-619, B-622 and B-626. The UNS number is NO6022.

Chemical Composition

| C | Cr | Co | Fe | Mn | Mo | Ni | P | Si | S | W | V |

| .010 max | 20-22.5 | 2.5 max | 2.0-6.0 | .50 max | 12.5-14.5 | Balance | .02 max | .08 max | .02 max | 2.5-3.5 | .35 max |

Mechanical Properties Typical Room Temperature Tensile Properties of Annealed Material

| Product Form | Tensile (ksi) | .2% Yield (ksi) | Elongation % | Hardness (HRb) |

| Plate (.25”-1.75”) | 112 | 53 | 62 | 89 |

| Sheet (.038”-.15”) | 122 | 63 | 54 | 93 |

| Bar (.50”-5.50”) | 115 | 55 | 60 | 89 |

Workability

Hastelloy C-22 can be fabricated using the same techniques as are used for alloys C-276 or C-4. It can be welded, forged, hot-upset and impact extruded. Alloy C-22 can also be successfully deep-drawn, spun, press formed or punched, although the alloy tends to work-harden.

Parts which have been hot formed or severely cold formed should be heat treated at 2050 °F and rapid quenched prior to final fabrication or installation.

Machinability

Hastelloy C-22 is considered moderate to difficult to machine, but it can still be machined using conventional production methods used for other alloys at a satisfactory rate. During machining, C-22 can harden rapidly, generate high heat, weld to the cutting tool surface, and resist metal removal, because of its high shear strength.

Fabrication of Hastelloy C-22

Although ductile enough to be formed by cold working, intermediate annealing may be necessary due to work hardening. Forging should be performed between 1750-2050° F followed by rapid cooling. Annealing can be performed at a temperature range between 2020-2150° F followed by a rapid quench. Cooling at an accelerated rate avoids the formation of detrimental phases which form between 1400-1800° F. Welding can be done by gas tungsten-arc, gas metal-arc and shielded metal-arc processes.

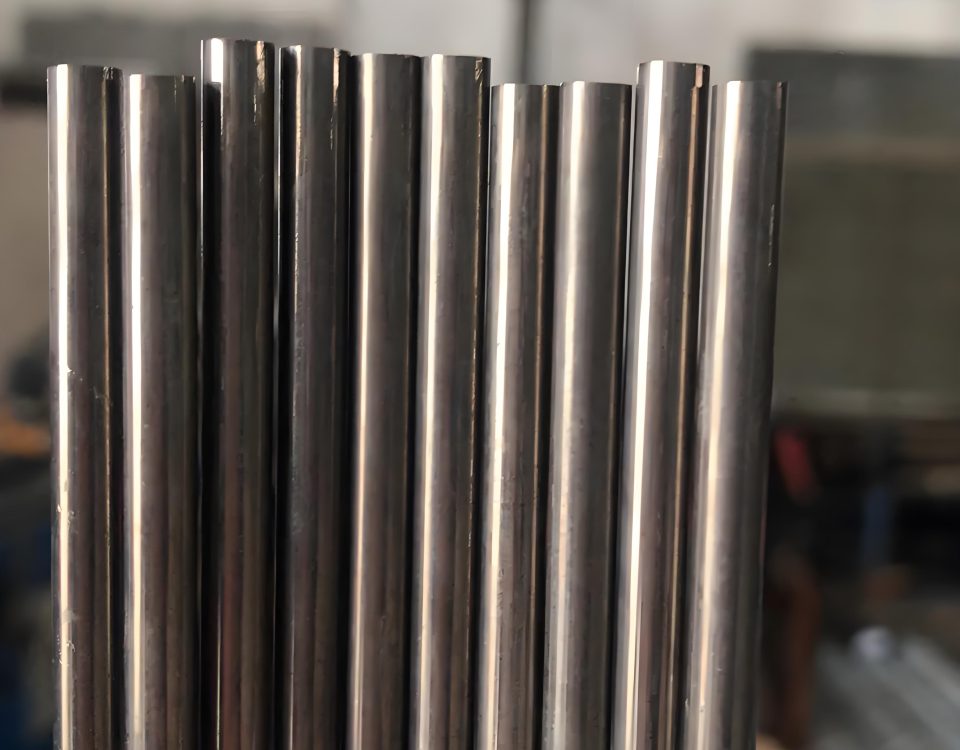

Seamless Construction

Hastelloy C22 pipes are available in seamless construction, providing a smooth and uniform surface that minimizes the risk of leaks and ensures efficient fluid flow.

Durability

These pipes are made from high-quality Hastelloy C22, offering exceptional durability and longevity. They resist corrosion, oxidation, and wear, ensuring reliable operation in the most demanding environments.

Versatility

Hastelloy C22 pipes are available in various sizes and wall thicknesses, allowing for versatile configurations in industrial systems. They can be customized to meet specific requirements, ensuring optimal performance.

Applications of Hastelloy C22 Pipes

Chemical Processing

In chemical processing plants, Hastelloy C22 pipes are preferred due to their resistance to corrosive chemicals and high temperatures. They ensure the safe and efficient transport of hazardous substances.

Pharmaceutical Industry

Hastelloy C22 pipes are used in the pharmaceutical industry to maintain the purity and integrity of products. Their smooth surfaces and resistance to corrosion make them suitable for sterile environments.

Oil and Gas Industry

In the oil and gas industry, Hastelloy C22 pipes are used in refineries and processing facilities to handle high-pressure and high-temperature applications. Their strength and corrosion resistance make them a reliable choice.

Marine and Offshore

Hastelloy C22 pipes are ideal for marine and offshore applications, where exposure to saltwater and harsh conditions is common. Their superior corrosion resistance ensures long-term reliability and safety.

Benefits of Using Hastelloy C22 Pipes

Superior Corrosion Resistance

Hastelloy C22 pipes offer superior corrosion resistance, ensuring long-lasting performance in aggressive environments. This reduces maintenance costs and extends the lifespan of industrial systems.

High Strength

The high strength of Hastelloy C22 pipes allows them to withstand high pressures and temperatures, making them suitable for demanding applications.

Cost-Effectiveness

While Hastelloy C22 pipes may have a higher initial cost, their durability and low maintenance requirements make them a cost-effective choice in the long run.

Conclusion

Hastelloy C22 N06022 2.4602 NiCr21Mo14W nickel-based alloy pipes are indispensable components in modern industrial systems, offering seamless construction, durability, and versatility. Their excellent corrosion resistance and high strength make them suitable for a wide range of applications, from chemical processing to marine environments. As industries continue to demand reliable and efficient solutions, Hastelloy C22 pipes will remain a preferred choice for enhancing the performance and reliability of industrial systems.

FAQ

1. What are the main advantages of Hastelloy C22 pipes?

The main advantages include superior corrosion resistance, high strength, and excellent performance in both oxidizing and reducing environments.

2. In which industries are Hastelloy C22 pipes commonly used?

Industries such as chemical processing, pharmaceuticals, oil and gas, and marine commonly use these pipes due to their excellent properties.

3. How do Hastelloy C22 pipes enhance the performance of industrial systems?

Their corrosion resistance, high strength, and durability ensure reliable operation and reduce maintenance costs, enhancing overall system performance.

4. Are Hastelloy C22 pipes cost-effective?

Yes, their durability and low maintenance requirements make them a cost-effective choice in the long run, despite a higher initial cost.

5. What is the significance of the UNS number N06022 for Hastelloy C22?

The UNS number N06022 is a standardized designation that identifies the specific composition and properties of Hastelloy C22, ensuring consistency and quality.