May 10, 2025

Super-Large Forged Flanges by Abter Steel Introduction to Abter Steel’s Forged Flanges At Abter Steel, we pride ourselves on being a global leader in the production of super-large forged flanges, engineered to meet the most demanding requirements of modern industrial applications. Our state-of-the-art manufacturing facilities and advanced forging technologies enable […]

April 9, 2025

Engineering Case Study: KDLFEED Company Factory Construction with Galvanized and Welded Steel Pipes Introduction Introduction to KDLFEED Company The KDLFEED Company is a well-established leader in the poultry processing industry, specializing in the production of high-quality chicken by-products and chicken meal powder. Headquartered in the Midwest of the United States, […]

January 14, 2025

Quality in Turning of Inconel X-750 Superalloy Steel Pipe Main Topics Subtopics Introduction to Inconel X-750 Overview of Inconel X-750; Chemical composition and properties; Applications in various industries Properties of Inconel X-750 Heat resistance; High-temperature performance; Corrosion resistance; Mechanical strength Challenges in Machining Inconel X-750 Work-hardening tendencies; Thermal conductivity; High […]

November 27, 2024

Structural Design of Pipeline Casing Pipes: A Comprehensive Guide Introduction The structural design of pipeline casing pipes is a critical aspect of engineering in industries such as oil and gas, water supply, and utilities. Casing pipes serve as protective enclosures for pipelines, shielding them from external loads, environmental factors, […]

October 28, 2024

Expansion Properties of J55 Casing Pipe Introduction J55 casing pipe is a commonly used grade of steel pipe in the oil and gas industry, particularly for well casing applications. It is part of the API 5CT specification, which defines the standards for casing and tubing used in oil and gas […]

October 10, 2024

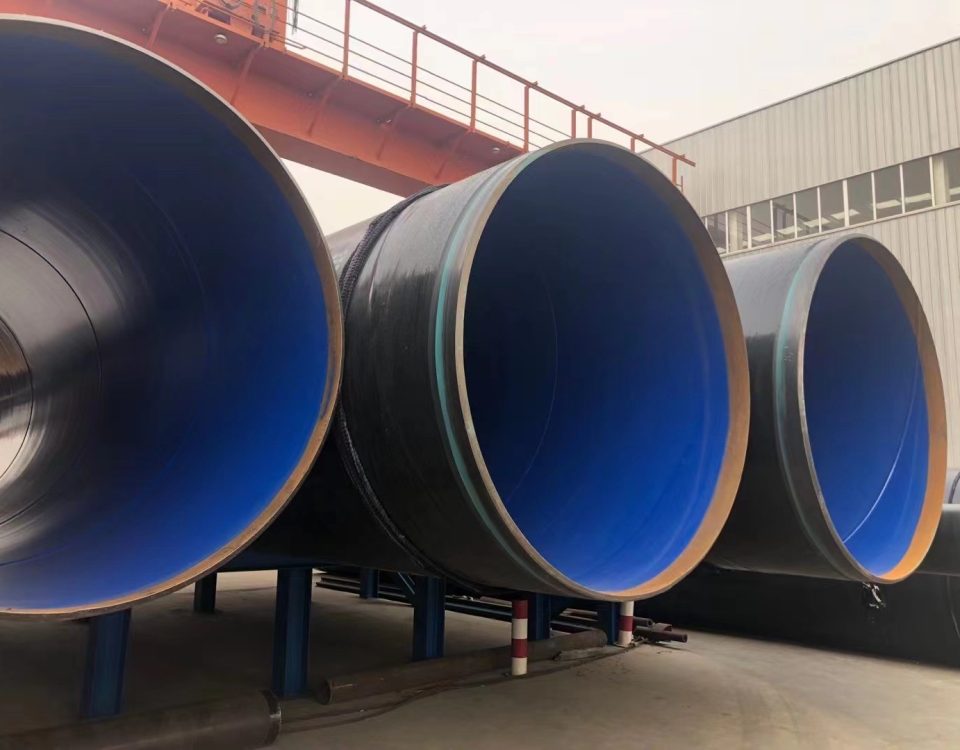

Introduction Steel water pipes are a cornerstone of modern infrastructure, playing a critical role in the distribution of water across urban and rural landscapes. Their design, lining, coating, joints, and installation are crucial factors that determine their efficiency, durability, and longevity. This comprehensive guide explores each of these aspects in […]

October 5, 2024

Introduction Stainless steel finds extensive use in piping distribution networks for potable water and is normally resistant to corrosion due to its chromium oxide film. However, smaller diameter pipes may experience altered electrochemical behaviors affecting long-term integrity depending on mass transport limitations. This paper investigates the influence of pipe diameter […]

September 7, 2024

Oil Casing Pipe Market Size, Growth Potential: Unleashing Growth Potential and Forecasted Outlook for 2024-2031 Introduction The oil casing pipe market is a critical component of the oil and gas industry, providing the necessary infrastructure for drilling and extraction operations. As the global demand for energy continues to rise, the […]

September 3, 2024

Global Pipeline Construction Outlook 2024: New LNG Terminals Call for More Pipelines Introduction The global energy landscape is undergoing a significant transformation, driven by the increasing demand for cleaner and more sustainable energy sources. Liquefied Natural Gas (LNG) has emerged as a key player in this transition, offering a cleaner […]

July 14, 2024

Oil Country Tubular Goods (OCTG) Industry Forecast and Potential Opportunities Analysis by 2023 Executive Summary The Oil Country Tubular Goods (OCTG) industry is integral to the oil and gas sector, encompassing a range of products such as casing, tubing, and drill pipe used in the drilling and production of oil […]