JIS G3461 STB410 Pipe for Durban Client

August 27, 2020

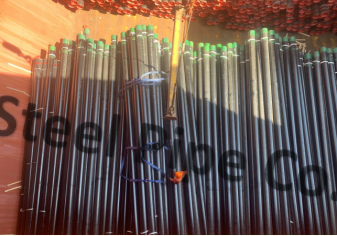

K55&N80-1 Casing Pipe for Poland Client

September 22, 2020Pipe with threading&coupling is threaded on both ends and comes with a pipe coupling to connect steel pipes together.

The seal provided by a threaded pipe joint depends upon multiple factors: the labyrinth seal created by the threads; a positive seal between the threads created by thread deformation when they are tightened to the proper torque; and sometimes on the presence of a sealing coating, such as thread seal tape or a liquid or paste pipe sealant such as pipe dope. Tapered thread joints typically do not include a gasket.

Especially precise threads are known as “dry fit” or “dry seal” and require no sealant for a gas-tight seal. Such threads are needed where the sealant would contaminate or react with the media inside the piping, e.g., oxygen service.

Tapered threaded fittings are sometimes used on plastic piping. Due to the wedging effect of the tapered thread, extreme care must be used to avoid overtightening the joint. The overstressed female fitting may split days, weeks, or even years after initial installation. Therefore many municipal plumbing codes restrict the use of threaded plastic pipe fittings.

Both British standard and National pipe thread standards specify a thread taper of 1:16; the change in diameter is one sixteenth the distance travelled along the thread. The nominal diameter is achieved some small distance (the “gauge length”) from the end of the pipe.