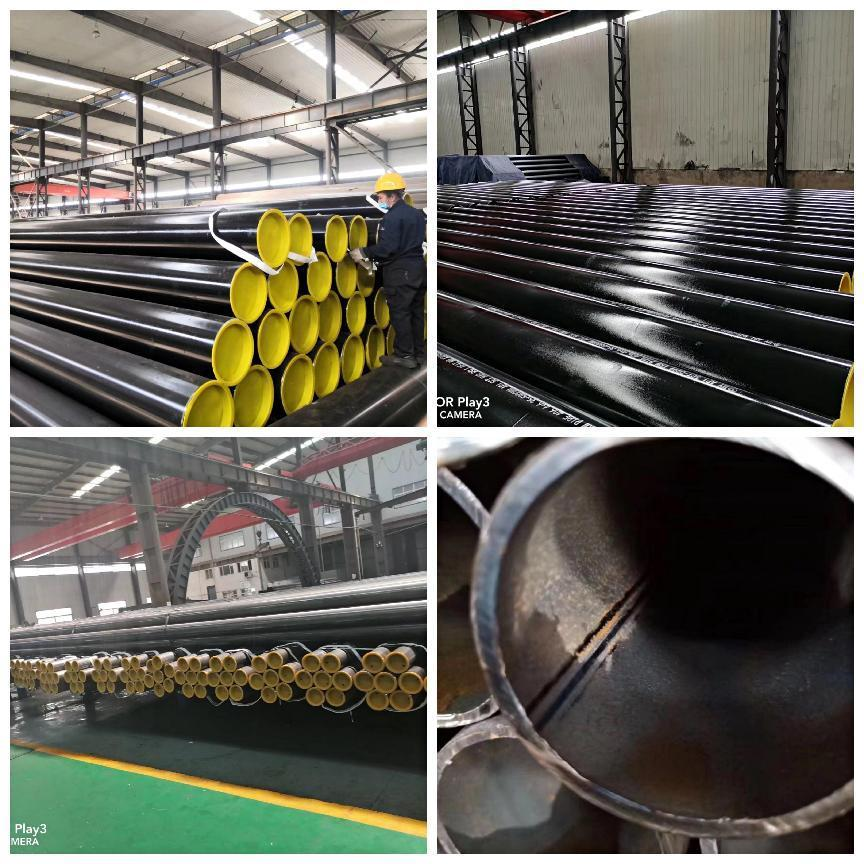

Internally Lined Carbon Steel API 5L Pipelines

June 4, 2025

Thick Wall Seamless Steel Pipe

June 5, 2025Comprehensive Scientific Analysis of Heavy Wall Stainless Steel Pipe

Material Composition and Manufacturing Process

Heavy wall stainless steel pipes, characterized by wall thicknesses ranging from 1 mm to 40 mm (SCH 5S to SCH XXS), are crafted from a variety of stainless steel alloys, including austenitic, duplex, and nickel-based grades, to meet demanding applications. Austenitic grades like TP304 (18-20% Cr, 8-10.5% Ni), TP316L (16-18% Cr, 10-14% Ni, 2-3% Mo), and 904L (19-23% Cr, 23-28% Ni, 4-5% Mo) offer excellent corrosion resistance due to their chromium and nickel content, which forms a self-healing Cr₂O₃ passive layer. Duplex grades, such as UNS S31803 and S32750 (22-25% Cr, 5-7% Ni, 3-4% Mo), combine austenitic and ferritic phases, doubling yield strength (450-650 MPa) while maintaining corrosion resistance. Nickel alloys, including Incoloy 825, Inconel 625, and Hastelloy C-276 (15-17% Mo, 14-16% Cr), are engineered for extreme environments, with high molybdenum and nickel (up to 60%) enhancing resistance to pitting and crevice corrosion. Manufacturing involves seamless processes—hot-rolling or cold-drawing solid billets—or welding (ERW, SAW), ensuring sizes from 6 mm to 630 mm OD and lengths up to 12 m. Standards like ASTM A312, EN 10216-5, and GOST 9941 ensure quality, with surface treatments (annealing, pickling, polishing) optimizing corrosion resistance and hygiene.

Mechanical Properties and Structural Integrity

Heavy wall stainless steel pipes are designed for high-pressure and high-stress applications, leveraging thick walls (SCH 80S to XXS) and robust alloy compositions. Austenitic grades like TP304 and TP316L provide tensile strengths of 515-620 MPa, yield strengths of 205-275 MPa, and elongation ≥35%, ensuring ductility under mechanical stress, per ASTM A312. Duplex grades, such as UNS S32750, offer higher tensile strengths (800-900 MPa) and yield strengths (550-650 MPa), ideal for structural and high-pressure fluid systems. Nickel alloys like Hastelloy C-276 achieve tensile strengths ≥690 MPa, with exceptional toughness in corrosive environments. The thick walls enhance hoop stress capacity, allowing pipes (e.g., 6” OD, SCH 160) to withstand pressures exceeding 100 MPa, per ASME B31.3. Seamless pipes ensure uniform grain structure, minimizing fatigue risks compared to welded pipes, which may exhibit HAZ vulnerabilities. Surface treatments, like bright annealing or polishing (180#-600#), reduce stress concentration points, enhancing durability in chemical, oil, and gas applications, per standards like DIN 17456 and GB/T 14976.

Corrosion Resistance and Environmental Performance

The corrosion resistance of heavy wall stainless steel pipes is driven by their alloying elements and passive oxide layer. Chromium (≥10.5%) forms a 1-3 nm Cr₂O₃ film, protecting against rust and chemical attack in corrosive water, acids, and chloride-rich environments. Molybdenum (2-17% in grades like TP316Ti, 904L, Hastelloy C-276) enhances pitting resistance, with 316L resisting pitting corrosion in 3.5% NaCl solutions at 50°C, per ASTM G48. Nickel (8-60%) improves resistance to stress corrosion cracking (SCC), critical for grades like Incoloy 825 in sour gas systems. Duplex grades like UNS S2205 outperform austenitic 304 in chloride-induced pitting, with critical pitting temperatures (CPT) >40°C. Nickel alloys, such as Monel 400, resist hydrochloric acid and seawater, enduring corrosion rates <0.1 mm/year in 10% HCl. Compared to carbon steel, stainless pipes reduce corrosion rates by 10-50 times, extending service life to 50+ years. Standards like ASTM A790 and GOST 9940 ensure low carbon (≤0.08%) and sulfur (≤0.03%), preventing sensitization and embrittlement, making these pipes ideal for marine, chemical, and power industries.

Comparative Analysis and Application Optimization

Heavy wall stainless steel pipes excel over carbon and alloy steel in corrosion resistance, hygiene, and extreme condition performance, though at higher cost (20-40% more). Austenitic grades like TP304 are cost-effective for general fluid delivery, while TP316L and 904L suit aggressive chemical environments due to molybdenum. Duplex grades (UNS S32750) offer twice the strength of 304, ideal for high-pressure oil and gas pipelines, per ASTM A789. Nickel alloys like Inconel 625 and Hastelloy C-276 are reserved for extreme corrosion, such as in H₂S-rich fields, but increase costs significantly. Seamless pipes provide superior pressure resistance (up to 150 MPa) versus welded, critical for boiler and nuclear applications, per ASTM A213. End finishes (plain, beveled, threaded) and surface treatments (sand blasting, shot blasting) ensure versatility, with delivery within 30 days. Future advancements include nanostructured coatings and real-time corrosion monitoring. Selection depends on environment and load: 304 for water, 316 for chemicals, S32750 for offshore, and C-276 for extreme acids. Tables below guide optimal application.

Dimension Range by Application

| Application | OD Range | WT Range | Length Range | Standards |

|---|---|---|---|---|

| Chemical Processing | 6 mm – 630 mm | SCH 40S, 80S, 160, XXS | Up to 12 m | ASTM A312, A213, EN 10216-5, GOST 9941 |

| Oil & Gas Pipelines | 1/2” – 24” | SCH 80S, 160, XXS | Up to 12 m | ASTM A789, A790, DIN 17456 |

| Power Generation | 1/8” – 16” | SCH 40S, 80S, 160 | Up to 12 m | ASTM A269, A511, GB/T 14976 |

| Marine & Offshore | 1/2” – 20” | SCH 80S, 160, XXS | Up to 12 m | ASTM A312, EN 10216-5, GOST 9940 |

Chemical Composition and Mechanical Properties

| Standard | Grade | C (%) | Si (%) | Mn (%) | P (%) | S (%) | Cr (%) | Ni (%) | Mo (%) | Tensile Strength (min MPa) | Yield Strength (min MPa) | Elongation (%) | |————–|———–|———–|————|————|———–|———–|————|————|——————————–|——————————|——————–| | ASTM A312 | TP304 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.0-20.0 | 8.0-10.5 | – | 515 | 205 | ≥35 | | ASTM A312 | TP316L | ≤0.035 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 485 | 170 | ≥35 | | ASTM A312 | 904L | ≤0.02 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.035 | 19.0-23.0 | 23.0-28.0 | 4.0-5.0 | 490 | 220 | ≥35 | | ASTM A789 | S31803 | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.03 | ≤0.02 | 21.0-23.0 | 4.5-6.5 | 2.5-3.5 | 620 | 450 | ≥25 | | ASTM A789 | S32750 | ≤0.03 | ≤0.80 | ≤1.20 | ≤0.035 | ≤0.02 | 24.0-26.0 | 6.0-8.0 | 3.0-5.0 | 800 | 550 | ≥15 | | ASTM A312 | Hastelloy C-276 | ≤0.01 | ≤0.08 | ≤1.00 | ≤0.04 | ≤0.03 | 14.5-16.5 | Bal (50-60)| 15.0-17.0 | 690 | 283 | ≥40 |

Extended Scientific Analysis of Heavy Wall Stainless Steel Pipe

Microstructural Evolution and Alloying Synergies

Heavy wall stainless steel pipes derive their exceptional performance from a tailored microstructure, shaped by alloying elements and advanced manufacturing processes. Austenitic grades like TP304 (18-20% Cr, 8-10.5% Ni) and TP316L (16-18% Cr, 10-14% Ni, 2-3% Mo) exhibit a face-centered cubic (FCC) structure, stabilized by nickel, which ensures high ductility (elongation ≥35%) and corrosion resistance via a Cr₂O₃ passive layer. Molybdenum in 316L and 904L (4-5% Mo) refines the microstructure, enhancing resistance to pitting in chloride environments (CPT >40°C, per ASTM G48). Duplex grades, such as UNS S32750 (24-26% Cr, 6-8% Ni, 3-5% Mo), combine austenitic and ferritic phases, doubling yield strength (550 MPa) compared to TP304 (205 MPa), per ASTM A789. Nickel alloys like Hastelloy C-276 (50-60% Ni, 15-17% Mo) form a solid-solution matrix, resisting aggressive acids (e.g., 10% HCl at <0.1 mm/year). Seamless manufacturing—hot-rolling or cold-drawing—produces uniform grain sizes (5-20 μm), while cold-drawing increases dislocation density, boosting strength. Annealing and pickling, per ASTM A312 and EN 10216-5, relieve stresses and enhance surface integrity, making these pipes ideal for high-pressure chemical, oil, and marine applications.

Thermal Stability and Extreme Environment Performance

Heavy wall stainless steel pipes excel in extreme thermal and corrosive conditions, driven by their alloy composition and thick walls (1-40 mm, SCH 80S-XXS). Austenitic grades like TP321H and TP347H, stabilized with titanium or niobium, resist intergranular corrosion at 500-800°C, per ASTM A213, suiting boiler and power generation systems. Duplex S32750 maintains strength and toughness from -50°C to 300°C, ideal for offshore pipelines. Nickel alloys, such as Inconel 625 (20-23% Cr, 8-10% Mo) and Hastelloy C-276, withstand temperatures up to 1000°C and aggressive media (e.g., H₂S, HCl), with corrosion rates <0.05 mm/year in sour gas environments. The thick walls enhance pressure capacity (e.g., 100 MPa for 4” OD, SCH 160), per ASME B31.3, and reduce thermal gradient stresses. Compared to carbon steel, stainless pipes resist oxidation and scaling 10-20 times better, extending life to 50+ years. Surface treatments—bright annealing or polishing (180#-600#)—minimize crevice corrosion, critical for food, chemical, and nuclear industries, per GOST 9941 and GB/T 14976.

Weld Imperfections and Integrity Enhancements

While seamless heavy wall stainless steel pipes dominate high-pressure applications, welded pipes, formed via ERW or SAW, are cost-effective but require careful management of weld zones. Welding heats austenitic grades like TP316Ti to 1400°C, forming a HAZ prone to sensitization if carbon exceeds 0.08%, reducing corrosion resistance. Duplex grades risk phase imbalance (e.g., excess ferrite), lowering toughness. Nickel alloys like Monel 400 demand precise filler metals to avoid hot cracking. Standards like ASTM A312 and DIN 17456 mandate low sulfur (≤0.03%) and phosphorus (≤0.045%) to minimize weld imperfections. Post-weld treatments, such as solution annealing or pickling, restore corrosion resistance, while NDT (ultrasonic, radiographic) ensures weld quality. Advanced laser welding and robotic systems promise minimal HAZ and improved uniformity. End finishes (plain, beveled, threaded) and packing (bundled or bulk) support versatile installation, with delivery within 30 days. Future innovations include self-healing coatings and real-time weld monitoring to enhance integrity in corrosive and high-pressure systems.

Dimension Range by Application

| Application | OD Range | WT Range | Length Range | Standards |

|---|---|---|---|---|

| Chemical Processing | 6 mm – 630 mm | SCH 40S, 80S, 160, XXS | Up to 12 m | ASTM A312, A213, EN 10216-5, GOST 9941 |

| Oil & Gas Pipelines | 1/2” – 24” | SCH 80S, 160, XXS | Up to 12 m | ASTM A789, A790, DIN 17456 |

| Power Generation | 1/8” – 16” | SCH 40S, 80S, 160 | Up to 12 m | ASTM A269, A511, GB/T 14976 |

| Marine & Offshore | 1/2” – 20” | SCH 80S, 160, XXS | Up to 12 m | ASTM A312, EN 10216-5, GOST 9940 |

Chemical Composition and Mechanical Properties

| Standard | Grade | C (%) | Si (%) | Mn (%) | P (%) | S (%) | Cr (%) | Ni (%) | Mo (%) | Tensile Strength (min MPa) | Yield Strength (min MPa) | Elongation (%) | |————–|———–|———–|————|————|———–|———–|————|————|——————————–|——————————|——————–| | ASTM A312 | TP304L | ≤0.035 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.0-20.0 | 8.0-12.0 | – | 485 | 170 | ≥35 | | ASTM A312 | TP317L | ≤0.035 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.0-20.0 | 11.0-15.0 | 3.0-4.0 | 515 | 205 | ≥35 | | ASTM A789 | S2205 | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.03 | ≤0.02 | 22.0-23.0 | 4.5-6.5 | 3.0-3.5 | 655 | 450 | ≥25 | | ASTM A789 | S32760 | ≤0.03 | ≤1.00 | ≤1.00 | ≤0.03 | ≤0.01 | 25.0-28.0 | 6.0-8.0 | 3.0-4.0 | 750 | 550 | ≥25 | | ASTM A312 | Inconel 625 | ≤0.10 | ≤0.50 | ≤0.50 | ≤0.015 | ≤0.015 | 20.0-23.0 | Bal (58-63)| 8.0-10.0 | 827 | 414 | ≥30 | | ASTM A312 | Hastelloy B-2 | ≤0.02 | ≤0.10 | ≤1.00 | ≤0.04 | ≤0.03 | ≤1.0 | Bal (65-70)| 26.0-30.0 | 760 | 350 | ≥40 |