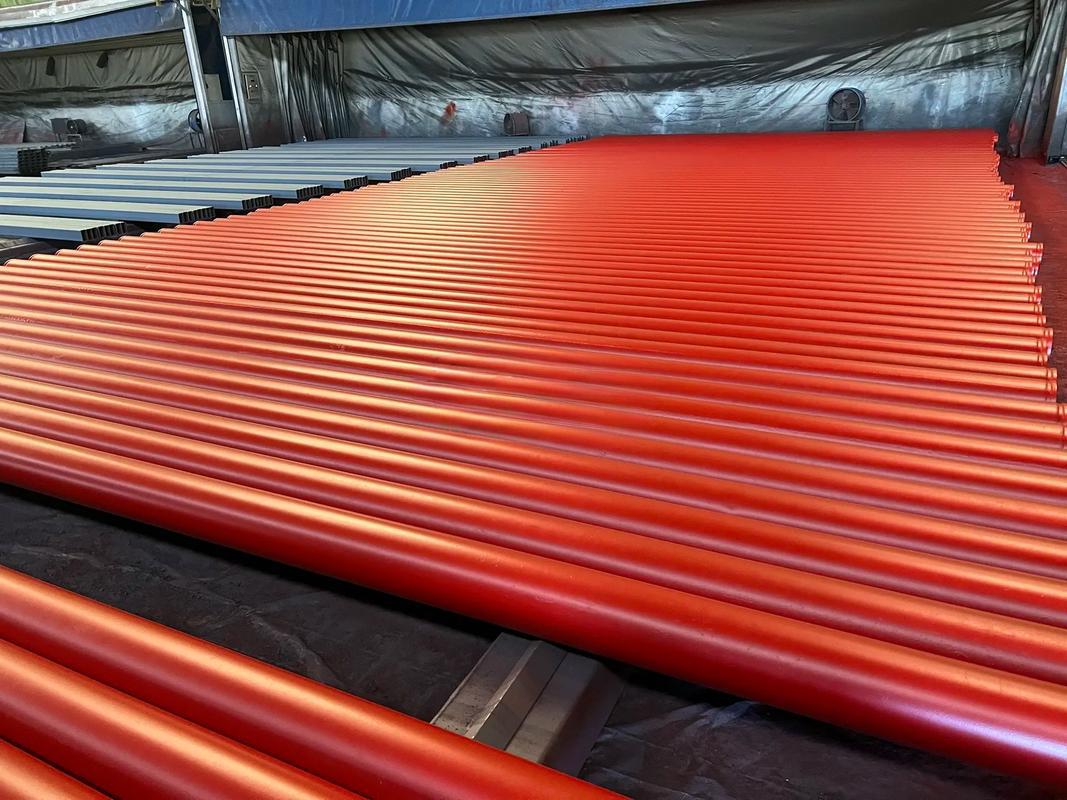

UL/FM Certified Fire Sprinkler Pipe

June 19, 2025

Grooved Pipe Coupling Fittings

June 28, 2025ASTM A795 is a cornerstone standard in the realm of steel tubing, specifically tailored for fire sprinkler systems and industrial applications. This specification, developed by the American Society for Testing and Materials (ASTM), outlines stringent requirements for black and hot-dipped galvanized welded and seamless steel pipes, ensuring they meet the rigorous demands of fire protection and industrial piping systems. Available in Nominal Pipe Sizes (NPS) ranging from 1/2 to 10 inches, ASTM A795 pipes come in two grades—Grade A and Grade B—with Grade B requiring post-weld heat treatment to eliminate untempered martensite, enhancing strength and durability.

Introduction to ASTM A795 Fire Sprinkler Pipe

Fire sprinkler systems are critical for safeguarding lives and property, and the pipes used in these systems must meet exacting standards to ensure reliability under extreme conditions. ASTM A795 specifies the requirements for both black and hot-dipped galvanized welded and seamless steel pipes designed for fire protection. These pipes are engineered to transport water, gas, or other extinguishing media in wet, dry, preaction, or deluge sprinkler systems. The standard covers pipes in NPS 1/2 to NPS 10, with wall thicknesses defined by schedules such as Sch 10 and Sch 40, which dictate the pipe’s ability to withstand pressure, corrosion, and thermal stress.

The ASTM A795 standard emphasizes material quality, dimensional accuracy, and rigorous testing to ensure safety and performance. Two grades are specified: Grade A and Grade B. Grade B pipes undergo post-weld heat treatment at a minimum of 1000°F (540°C) to eliminate untempered martensite, a brittle microstructure that can compromise pipe integrity. This treatment enhances the pipe’s strength and durability, making Grade B particularly suitable for demanding applications. Additionally, ASTM A795 mandates protective coatings, such as hot-dip galvanizing, to provide corrosion resistance, with a minimum zinc coating weight of 1.5 oz/ft² (0.46 kg/m²) to ensure longevity in harsh environments.

Sch 10 and Sch 40 pipes differ primarily in their wall thickness, which affects their pressure ratings, weight, and suitability for specific fire protection applications. Sch 10 pipes are considered lightweight, with thinner walls, while Sch 40 pipes have thicker walls, offering greater strength and pressure resistance. This article delves into the technical specifications, performance metrics, and practical considerations of these two schedules, supported by detailed tables and a scientific analysis of their differences.

Pipe Sizes and Dimensional Specifications

The dimensions of ASTM A795 fire sprinkler pipes are critical for ensuring compatibility with fittings, proper flow rates, and structural integrity in fire protection systems. Pipe sizes are expressed in Nominal Pipe Size (NPS), which corresponds to the approximate internal diameter of the pipe, and wall thickness is defined by the schedule. Sch 10 and Sch 40 pipes are available in NPS 1/2 to NPS 10, but their wall thicknesses differ significantly, impacting their weight, pressure capacity, and installation requirements.

Below is a detailed comparison of Sch 10 and Sch 40 pipe dimensions, weights, and test pressures, as specified by ASTM A795 and referenced from industry standards such as ASME B36.10M. The data is sourced from reliable manufacturers like abtersteel.

Table 1: Dimensions, Weights, and Test Pressures for ASTM A795 Sch 10 and Sch 40 Pipes

| NPS (in) | OD (in) | Sch 10 Wall Thickness (in) | Sch 10 Weight (lb/ft) | Sch 10 Test Pressure (psi) | Sch 40 Wall Thickness (in) | Sch 40 Weight (lb/ft) | Sch 40 Test Pressure (psi) |

|---|---|---|---|---|---|---|---|

| 1/2 | 0.840 | 0.083 | 0.67 | 700 | 0.109 | 0.85 | 700 |

| 3/4 | 1.050 | 0.083 | 0.86 | 700 | 0.113 | 1.13 | 700 |

| 1 | 1.315 | 0.109 | 1.41 | 700 | 0.133 | 1.68 | 700 |

| 1-1/4 | 1.660 | 0.109 | 1.81 | 1000 | 0.140 | 2.27 | 1000 |

| 1-1/2 | 1.900 | 0.109 | 2.09 | 1000 | 0.145 | 2.72 | 1000 |

| 2 | 2.375 | 0.109 | 2.64 | 1000 | 0.154 | 3.65 | 1000 |

| 2-1/2 | 2.875 | 0.120 | 3.53 | 1000 | 0.203 | 5.79 | 1000 |

| 3 | 3.500 | 0.120 | 4.34 | 1000 | 0.216 | 7.58 | 1000 |

| 4 | 4.500 | 0.120 | 5.62 | 1000 | 0.237 | 10.79 | 1000 |

| 5 | 5.563 | 0.134 | 7.77 | 1000 | 0.258 | 14.62 | 850 |

| 6 | 6.625 | 0.134 | 9.29 | 1000 | 0.280 | 18.97 | 850 |

| 8 | 8.625 | 0.188 | 16.94 | 800 | 0.322 | 28.55 | 800 |

| 10 | 10.750 | 0.188 | 21.23 | 800 | 0.365 | 40.48 | 800 |

Source: Adapted from ASTM A795 and ASME B36.10M, as provided by abtersteel.

Analysis of Dimensional Differences

The table highlights the key differences between Sch 10 and Sch 40 pipes. Sch 10 pipes have thinner walls, resulting in lower weight per unit length, which makes them easier to handle and install. For example, a 2-inch NPS Sch 10 pipe has a wall thickness of 0.109 inches and weighs 2.64 lb/ft, while the same size in Sch 40 has a wall thickness of 0.154 inches and weighs 3.65 lb/ft. This difference becomes more pronounced in larger sizes, such as 8-inch NPS, where Sch 10 weighs 16.94 lb/ft compared to Sch 40’s 28.55 lb/ft.

Sch 40 pipes, with their thicker walls, offer greater structural integrity and pressure resistance, making them suitable for applications requiring higher strength. However, the increased weight can complicate installation and increase material costs. Both schedules are tested to similar hydrostatic pressures for smaller sizes (e.g., 700–1000 psi for NPS 1/2 to 4), but Sch 40 pipes may have slightly lower test pressures in larger sizes (e.g., 850 psi for NPS 5 and 6) due to their thicker walls, which provide inherent strength.

The choice between Sch 10 and Sch 40 depends on the specific requirements of the fire sprinkler system, including pressure ratings, flow rates, and installation constraints. Sch 10 pipes are often used in low- to medium-pressure systems, while Sch 40 pipes are preferred for high-pressure or high-load environments.

Material and Coating Requirements

ASTM A795 pipes are made from carbon steel, with specific chemical and mechanical properties defined for Grades A and B. Grade A is suitable for general applications, while Grade B, with its post-weld heat treatment, offers enhanced strength and durability. The standard requires that pipes be either black (uncoated) or hot-dipped galvanized to provide corrosion resistance. Galvanizing involves dipping the pipe in molten zinc to create a protective coating with a minimum weight of 1.5 oz/ft² (0.46 kg/m²), ensuring durability in both indoor and outdoor environments.

Corrosion Resistance and Coating Specifications

The galvanizing process is critical for fire sprinkler pipes, as it protects against rust and corrosion, which can compromise the pipe’s ability to deliver water effectively. ASTM A795 specifies that the zinc coating must be free of defects such as uncoated areas, blisters, flux deposits, or heavy zinc deposits that could interfere with the pipe’s performance. For example, lumps or projections in the coating are not permitted, as they could obstruct water flow or affect fitting compatibility.

Sch 10 and Sch 40 pipes both benefit from galvanizing, but the thinner walls of Sch 10 pipes make the coating’s quality particularly important. A thinner wall is more susceptible to corrosion penetration, so the zinc layer must be uniformly applied to ensure long-term protection. Sch 40 pipes, with their thicker walls, offer an additional layer of durability, as the steel itself provides more material to resist corrosion before failure.

Alternative coatings, such as black lacquer, epoxy, or antimicrobial coatings like pe coating, may be applied based on project requirements. These coatings enhance resistance to microbial-induced corrosion (MIC), which can be a concern in stagnant water systems. Manufacturers like Bull Moose Tube and Wheatland Tube offer proprietary coatings that exceed ASTM A795 requirements, providing additional protection for both Sch 10 and Sch 40 pipes.

Mechanical Properties

The mechanical properties of ASTM A795 pipes, including yield strength, tensile strength, elongation, and hardness, are critical for ensuring performance under pressure and thermal stress. Grade B pipes, with their heat-treated weld seams, exhibit superior tensile strength (typically 60,000 psi minimum) compared to Grade A (48,000 psi minimum). This makes Grade B Sch 40 pipes particularly suitable for high-pressure systems, where the thicker walls and enhanced material properties provide greater safety margins.

Sch 10 pipes, while lighter, have lower pressure ratings due to their thinner walls. However, their mechanical properties are sufficient for most fire sprinkler applications, especially in systems with lower operating pressures. The choice between Sch 10 and Sch 40 must consider the balance between material strength, weight, and cost, with Sch 40 offering greater robustness at the expense of increased material and installation costs.

Testing and Quality Assurance

ASTM A795 mandates rigorous testing to ensure the quality and reliability of fire sprinkler pipes. Two primary testing methods are specified: hydrostatic testing and nondestructive electric testing (NDT). Hydrostatic testing involves filling the pipe with water and subjecting it to high pressure to detect leaks or weaknesses in the pipe wall. NDT, an alternative method, uses electrical currents to identify defects without damaging the pipe, offering faster testing times and less disruption to construction schedules.

Hydrostatic Testing

Hydrostatic testing is a critical quality control measure for both Sch 10 and Sch 40 pipes. The test pressures, as shown in Table 1, range from 700 to 1000 psi for most sizes, ensuring that the pipes can withstand the pressures encountered in fire sprinkler systems. Sch 10 pipes, with their thinner walls, require careful testing to ensure that they meet these pressure requirements without deformation or failure. Sch 40 pipes, with their thicker walls, inherently provide greater resistance to pressure, but they are still subjected to the same rigorous testing to ensure consistency.

Nondestructive Electric Testing (NDT)

NDT is particularly valuable in the fire sprinkler industry, as it allows for rapid, non-invasive testing of welds and pipe material. This method is especially effective for detecting defects in the weld area of ERW (electric resistance welded) pipes, which are common in both Sch 10 and Sch 40 configurations. ASTM A795 requires that each pipe be tested individually if NDT is used, ensuring that no defects go undetected. The use of NDT is becoming increasingly common due to its efficiency and reliability, particularly for large-scale projects where time is a critical factor.

Flattening Test

The flattening test is another key requirement of ASTM A795, designed to assess the ductility and soundness of the pipe. The test involves flattening the pipe between parallel plates in three stages:

- Ductility of the Weld: The pipe is flattened until the distance between the plates is less than two-thirds of the original outside diameter, checking for cracks or breaks in the weld.

- Ductility Exclusive of the Weld: The pipe is further flattened until the distance is less than one-third of the original outside diameter, ensuring the pipe body remains intact.

- Soundness: The pipe is flattened until it breaks or the opposite walls meet, verifying the overall integrity of the material.

Both Sch 10 and Sch 40 pipes must pass this test, but the thinner walls of Sch 10 pipes make them more susceptible to deformation, requiring precise manufacturing to meet the standard’s requirements. Sch 40 pipes, with their greater thickness, typically exhibit better performance in the flattening test, reflecting their enhanced structural integrity.

Performance Analysis: Sch 10 vs. Sch 40

The choice between Sch 10 and Sch 40 ASTM A795 pipes depends on several factors, including system pressure, flow requirements, installation constraints, and budget considerations. Below is a detailed comparison of their performance characteristics, supported by scientific analysis.

Pressure and Load Capacity

Sch 40 pipes, with their thicker walls, have higher pressure ratings and load-bearing capacities than Sch 10 pipes. For example, in a 4-inch NPS pipe, the Sch 40 wall thickness of 0.237 inches provides significantly greater strength than the Sch 10 wall thickness of 0.120 inches. This makes Sch 40 pipes ideal for high-pressure systems or applications requiring seismic bracing, where the pipe must withstand lateral forces during an earthquake.

Sch 10 pipes, while less robust, are sufficient for low- to medium-pressure systems, such as residential or light commercial fire sprinkler systems. Their thinner walls reduce material costs and weight, making them easier to handle and install. However, they may require additional support in high-load environments to prevent deformation.

Flow Characteristics

The internal diameter of a pipe affects its flow capacity, which is critical for delivering water efficiently in a fire sprinkler system. Sch 10 pipes, with their thinner walls, have a slightly larger internal diameter than Sch 40 pipes of the same NPS. For example, a 2-inch NPS Sch 10 pipe has an internal diameter of approximately 2.157 inches, compared to 2.067 inches for Sch 40. This difference results in a slightly higher flow rate for Sch 10 pipes, which can be advantageous in systems where maximizing water delivery is a priority.

However, the difference in flow capacity is often minimal and may not justify choosing Sch 10 over Sch 40 in high-pressure systems, where structural integrity is paramount. Engineers must calculate the required flow rate using formulas such as:

Where:

-

is the flow rate (m³/h),

-

is the cross-sectional area of the pipe (m²),

-

is the velocity of water flow (m/s).

The larger internal diameter of Sch 10 pipes increases

, potentially allowing higher

for the same

, but this must be balanced against the pipe’s pressure limitations.

Cost and Installation Considerations

Sch 10 pipes are generally more cost-effective than Sch 40 pipes due to their lower material content and weight. This can result in significant savings in large-scale projects, where thousands of feet of pipe are required. Additionally, the lighter weight of Sch 10 pipes reduces labor costs and simplifies installation, particularly in overhead systems where heavy lifting is a concern.

Sch 40 pipes, while more expensive, offer greater durability and are often specified in projects where long-term reliability is critical, such as in industrial facilities or high-rise buildings. The thicker walls also allow for threading, grooving, or welding, providing greater flexibility in joining methods compared to Sch 10 pipes, which are typically limited to roll-grooved or plain-end fittings due to their thinner walls.

Corrosion Resistance and Longevity

Both Sch 10 and Sch 40 pipes benefit from hot-dip galvanizing, which provides a robust barrier against corrosion. However, the thinner walls of Sch 10 pipes make them more vulnerable to corrosion penetration over time, particularly in environments with high humidity or chemical exposure. Sch 40 pipes, with their greater material thickness, offer a longer service life in such conditions, as the steel can withstand more corrosion before failure.

Proprietary coatings, enhance the corrosion resistance of both schedules, but their impact is more significant for Sch 10 pipes, where the thinner walls rely heavily on the coating’s integrity. Regular maintenance and inspections are essential for both schedules to ensure long-term performance, particularly in systems exposed to stagnant water or harsh environmental conditions.

Practical Applications and Industry Considerations

ASTM A795 Sch 10 and Sch 40 pipes are used in a wide range of fire protection systems, from residential buildings to large industrial facilities. Sch 10 pipes are commonly used in light commercial and residential applications, where lower pressure ratings and cost savings are prioritized. For example, a small office building with a wet-pipe sprinkler system may use Sch 10 pipes to deliver water efficiently while minimizing installation costs.

Sch 40 pipes are preferred in high-pressure systems, such as deluge or preaction systems in industrial plants, where the pipes must withstand higher pressures and potential seismic loads. Their thicker walls also make them suitable for applications requiring threading or welding, such as in complex piping networks with multiple fittings.

Industry standards, such as NFPA 13 (Standard for the Installation of Sprinkler Systems), specify the use of ASTM A795 pipes for fire protection, with Sch 10 and Sch 40 being the most common schedules. Contractors must ensure compliance with local fire codes, which may impose additional requirements on pipe selection, installation, and testing.

ASTM A795 Sch 10 and Sch 40 fire sprinkler pipes are both critical components of fire protection systems, each offering distinct advantages based on their dimensional and performance characteristics. Sch 10 pipes, with their thinner walls and lower weight, are cost-effective and suitable for low- to medium-pressure applications, offering slightly higher flow rates due to their larger internal diameters. Sch 40 pipes, with their thicker walls, provide superior strength and pressure resistance, making them ideal for high-pressure or high-load environments.

The choice between Sch 10 and Sch 40 depends on a careful evaluation of system requirements, including pressure ratings, flow needs, installation constraints, and budget considerations. Both schedules benefit from ASTM A795’s rigorous standards for material quality, galvanizing, and testing, ensuring reliability in fire protection applications. By understanding the technical specifications and performance differences outlined in this article, engineers and contractors can make informed decisions to optimize the safety and efficiency of their fire sprinkler systems.