FREIGHT TRANSPORT

May 14, 2019

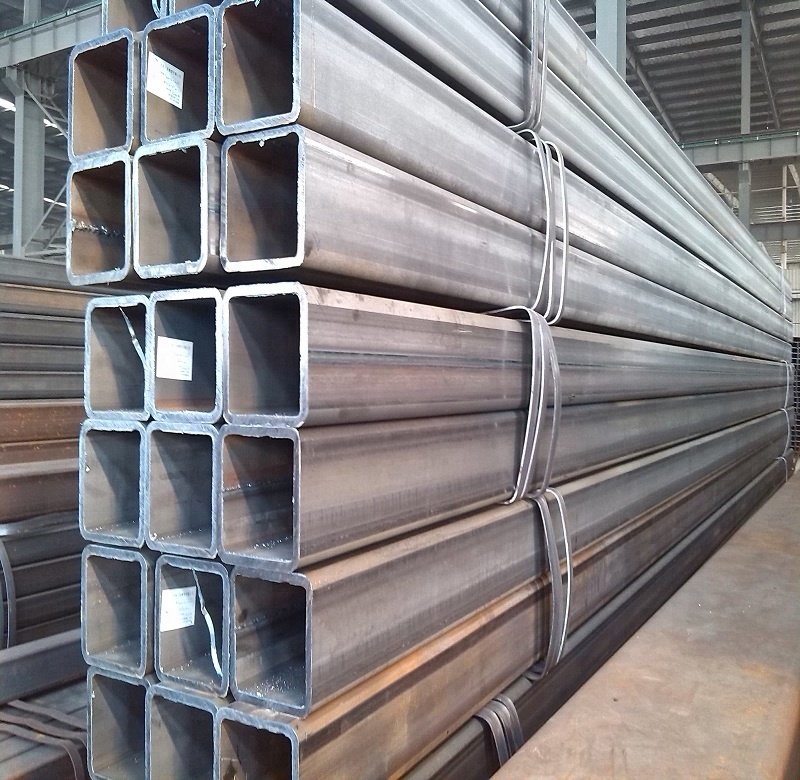

Corten Steel ASTM A606 Corrosion Resistant Square & Rectangular Tube/Pipe

December 10, 2019ASTM A53 is one of the widely used standard specification for Steel Pipe that used in the Oil and Gas as well as other process industries also. ASTM A 53 Grade B is more popular than other grades. These pipes can be bare pipes without any coating, or it may be Hot-Dipped or Zinc-Coated and manufactured by Welding or by a Seamless manufacturing process.

In Oil and Gas ASTM A53 pipes are used in the structural and non-critical application. They are not used in hydrocarbon services or any services that involve pressure and temperature.

Pipe Size and Types Covered in ASTM A53

Pipe size NPS 1/8” to NPS 26” are covered in this standard. This is equivalent to DN 6 to DN 650.

There are three types of pipes covered in ASTM A53.

Type F – Furnace-butt welded continuous welded Pipe.

Grade A

This type of pipe is made by continues coil, and the longitudinal joint is welded by forge welding. In which set of rollers is used that create mechanical pressure to joined heated ends.

Type E – Electric-resistance welded.

Grade A

Grade B

This type of pipe is made by continues coil, and the longitudinal joint is welded heat produced by electric resistance between opposite ends of the pipe. In this process also, set of rollers are used to join heated ends. The weld seam of Grade Bpipes is heat treated after welding to a minimum of 540°C.

Type S – Seamless

Grade A

Grade B

These types of pipes are manufactured using the

extrusion method.

Raw steel that used to manufacture pipes is produced by open-hearth, electric-furnace, or basic-oxygen method.