komposisi 201 Stainless Steel Pipes

Mungkin 21, 2023

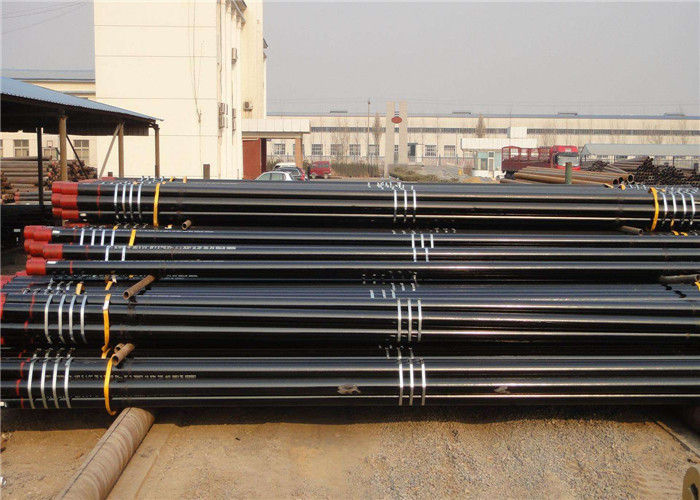

J55 K55 HFW Status Penyelidikan dan Pembangunan Paip Casing Minyak dan Prospek

Jun 2, 2023Teknologi latar belakang: Paip keluli A335.P91 domestik adalah bersamaan dengan keluli tahan haba martensit 9Cr-1Mo di China, dicirikan oleh diameter besar dan berdinding tebal (508×32.54mm) paip, digunakan terutamanya dalam penjanaan kuasa dan industri kimia sebagai saluran paip wap tekanan tinggi atau saluran paip bahagian pemanasan semula.

Apabila paip keluli A335.P91 digunakan sebagai saluran paip wap tekanan tinggi dalam industri kimia, ia dikehendaki bahawa kekerasan paip keluli yang dikimpal, selepas rawatan haba, mematuhi ASME (Persatuan Jurutera Mekanikal Amerika) spesifikasi, dengan nilai kekerasan Brinell (selepas ini dirujuk sebagai kekerasan) kurang daripada atau sama dengan 241HB.

Rawatan haba selepas kimpalan terutamanya bertujuan untuk melegakan tekanan yang besar di kawasan yang dikimpal, memperbaiki struktur mikro logam kimpalan dan zonnya yang terjejas haba, menukar martensit dipadamkan kepada martensit terbaja, mengurangkan kekerasan kawasan sendi, meningkatkan keliatan, kebolehubah bentuk, dan kekuatan daya tahan suhu tinggi. Pada masa ini, proses rawatan haba untuk paip keluli melibatkan pembalut pemanas di sekeliling jahitan kimpalan, penebatnya dengan penebat haba, dan mengekalkan suhu 760±10℃ untuk 5 jam.

Semasa musim sejuk di kawasan utara, semasa menjalankan rawatan haba pada paip keluli A335.P91, suhu rendah, yang boleh turun kepada -20 ℃, dan angin kencang boleh menjejaskan rawatan haba, menghasilkan nilai kekerasan lebih kurang 300HB untuk jahitan kimpalan selepas rawatan haba, gagal memenuhi spesifikasi ASME. Nilai kekerasan yang tinggi pada jahitan kimpalan meningkatkan kerapuhan, tekanan sisa, dan terdedah kepada keretakan. Pada musim sejuk yang sangat sejuk, melakukan rawatan haba pada diameter besar, paip keluli berdinding tebal sering menghadapi isu-isu yang disebutkan di atas, dengan nilai kekerasan yang terlalu tinggi untuk jahitan kimpalan, tidak dapat memenuhi spesifikasi ASME, dan tidak dapat menjamin kualiti kimpalan.

Kandungan ciptaan

Untuk menyelesaikan masalah kekerasan jahitan kimpalan paip keluli aloi A335 berdiameter besar dan paip keluli aloi A335 berdinding tebal tidak memenuhi keperluan spesifikasi ASME selepas rawatan haba pada musim sejuk, Ciptaan ini mencadangkan kaedah untuk membantu rawatan haba A335 paip keluli aloi kimpalan, yang boleh menjadikan kekerasan jahitan kimpalan paip keluli memenuhi keperluan spesifikasi ASME selepas rawatan haba, dan meningkatkan kualiti kimpalan bahan asas.

GRED KELULI ASTM A335

Jenis keluli aloi yang dilindungi oleh spesifikasi ASTM A335 – ASME SA335 direka bentuk dengan awalan “P”, daripada P5 kepada P92. Gred P11/P22 dan P91/92 biasanya terdapat di stesen janakuasa, manakala gred P5 dan P9 lebih biasa digunakan dalam industri petrokimia. Gred P9 dan P91 ada dalam senarai, semakin mahal (paip lancar P91 mungkin berharga lebih kurang 5€ setiap kg.).

| ASTM A335 Keluli Aloi Rendah (Gred) |

US bersamaan |

C≤ | MN | P≤ | S≤ | Si≤ | TK | MO |

| P1 | K11522 | 0.10~ 0.20 | 0.30~ 0.80 | 0.025 | 0.025 | 0.10~0.50 | – | 0.44~ 0.65 |

| P2 | K11547 | 0.10~ 0.20 | 0.30~ 0.61 | 0.025 | 0.025 | 0.10~ 0.30 | 0.50~0.81 | 0.44~ 0.65 |

| P5 | K41545 | 0.15 | 0.30~ 0.60 | 0.025 | 0.025 | 0.5 | 4.00~6.00 | 0.44~ 0.65 |

| P5B | K51545 | 0.15 | 0.30~ 0.60 | 0.025 | 0.025 | 1.00~2.00 | 4.00~6.00 | 0.44~ 0.65 |

| P5c | K41245 | 0.12 | 0.30~ 0.60 | 0.025 | 0.025 | 0.5 | 4.00~6.00 | 0.44~ 0.65 |

| P9 | S50400 | 0.15 | 0.30~ 0.60 | 0.025 | 0.025 | 0.50~1.00 | 8.00~10.00 | 0.44~ 0.65 |

| P12 | K11562 | 0.05~ 0.15 | 0.30~ 0.60 | 0.025 | 0.025 | 0.5 | 0.80~ 1.25 | 0.44~ 0.65 |

| P22 | K21590 | 0.05~ 0.15 | 0.30~ 0.60 | 0.025 | 0.025 | 0.5 | 1.90~ 2.60 | 0.87~ 1.13 |

| P91 | K91560 | 0.08~ 0.12 | 0.30~ 0.60 | 0.02 | 0.01 | 0.20~0.50 | 8.00~9.50 | 0.85~ 1.05 |

| P92 | K92460 | 0.07~ 0.13 | 0.30~ 0.60 | 0.02 | 0.01 | 0.5 | 8.50~9.50 | 0.30~ 0.60 |

SIFAT-SIFAT MEKANIKAL

| A335 Paip Aloi Rendah | Nombor UNS | Kekuatan Hasil ksi | Kekuatan Tegangan ksi | Elongation % | Rockwell | Brinell |

| P1 | K11522 | 30 | 55 | 30 | – | – |

| P2 | K11547 | 30 | 55 | 30 | – | – |

| P5 | K41545 | 40 | 70 | 30 | – | 207 maksimum |

| P9 | S50400 | 30 | 60 | 30 | – | – |

| P12 | K11562 | 32 | 60 | 30 | – | 174 maksimum |

| P22 | K21590 | 30 | 60 | 30 | – | – |

| P91 | K91560 | 60 | 85 | 20 | – | – |

Kaedah untuk membantu rawatan haba kimpalan paip keluli aloi A335 dalam ciptaan ini termasuk langkah-langkah berikut:

(1) Balut pemanas di sekeliling jahitan kimpalan;

(2) Untuk kimpalan bahagian paip panjang: bungkus pemanas pada kedudukan 550-700 mm dari pemanas yang dibalut pada jahitan kimpalan pada paip keluli, dan gunakan bahan penebat haba untuk membalut keseluruhan paip keluli;

(3) Untuk kimpalan paip pendek dan siku: gunakan bahan penebat haba untuk membalut keseluruhan paip keluli;

(4) Mulakan rawatan haba paip keluli, mengawal suhu pada jahitan kimpalan kepada 760±10℃ semasa proses rawatan haba, dan masa rawatan haba ialah 5 jam; semasa proses rawatan haba, untuk kimpalan bahagian paip panjang, pemanas pada jarak 550-700 mm dari pemanas yang dibalut pada jahitan kimpalan akan mengawal suhu paip keluli aloi A335 yang dibalut oleh pemanas kepada 200-300 ℃ sehingga rawatan haba selesai.

Dalam langkah-langkah di atas (2) dan (3), ketebalan bahan penebat haba yang dibalut pada paip keluli aloi A335 adalah 200-250 mm.

Dalam langkah yang disebutkan di atas (4), kaedah ini juga termasuk menggunakan termometer inframerah untuk mengukur suhu bahan penebat pada jahitan kimpalan. Jika suhu lapisan paling luar bahan penebat lebih tinggi daripada 40 ℃, satu lagi lapisan bahan penebat akan dibalut.

Kaedah juga termasuk langkah (5): selepas rawatan haba selesai, apabila suhu bahan penebat jatuh di bawah 20 ℃, keluarkan bahan penebat.

Pemanas yang disebut adalah lembaran pemanas elektrik.

Bahan penebat yang dinyatakan ialah kapas penebat aluminium silikat.

Pencipta mendapati dalam eksperimen bahawa semasa proses rawatan haba paip keluli berdiameter besar dan berdinding tebal, bukan sahaja suhu pada jahitan kimpalan tinggi, tetapi suhu pada kedudukan 550-700 mm dari pemanas yang dibalut pada jahitan kimpalan pada paip keluli juga tinggi, mencapai sehingga 109 ℃. Ini menunjukkan bahawa terdapat pemindahan haba yang ketara antara jahitan kimpalan dan kedudukan 550-700 mm dari pemanas yang dibalut pada jahitan kimpalan, dan pelesapan haba paip keluli adalah pantas. Dalam kaedah sedia ada, tiada langkah perlindungan untuk kedudukan tersebut 550-700 mm dari jahitan kimpalan pada paip keluli. sebagai tambahan, semasa pembinaan musim sejuk, suhu boleh turun kepada -20 ℃, dan ada angin kencang. Faktor luaran ini mempengaruhi suhu kedudukan

550-700 mm dari pemanas yang dibalut pada jahitan kimpalan pada paip keluli, yang seterusnya mempengaruhi suhu pada jahitan kimpalan, akhirnya menjejaskan nilai kekerasan jahitan kimpalan selepas rawatan haba.

Kaedah ciptaan ini juga membalut pemanas pada kedudukan 550-700 mm dari pemanas yang dibalut pada jahitan kimpalan pada paip keluli untuk memberikan pampasan suhu untuk kedudukan 550-700 mm dari pemanas yang dibalut pada jahitan kimpalan, dan mengawal suhu pada kedudukan 550-700 mm dari pemanas yang dibalut di sekeliling jahitan kimpalan kepada 200-300 ℃. Berbanding dengan kaedah sedia ada, ini mengurangkan pemindahan haba antara jahitan kimpalan dan kedudukan 550-700 mm dari pemanas yang dibalut pada jahitan kimpalan pada paip keluli, dan sangat mengurangkan kesan suhu dan faktor lain pada suhu pada jahitan kimpalan melalui kedudukan 550-700 mm dari pemanas yang dibalut pada jahitan kimpalan pada paip keluli. Ini melambatkan kadar pelesapan haba paip keluli, memastikan suhu paip keluli semasa proses rawatan haba, meningkatkan kualiti rawatan haba, dan menggunakan kaedah ciptaan ini untuk rawatan haba paip keluli. Nilai kekerasan pada jahitan kimpalan adalah kurang daripada atau sama dengan 241HB, yang memenuhi keperluan spesifikasi ASME. Kaedah ciptaan ini juga menggunakan bahan penebat haba untuk membalut keseluruhan paip keluli, mengurangkan lagi kesan suhu dan faktor lain ke atas suhu pada jahitan kimpalan.

Penerangan gambar dilampirkan

Rajah 1 ialah gambarajah skematik rawatan haba jahitan kimpalan bahagian paip panjang menggunakan kaedah ciptaan ini;

Rajah 2 ialah gambarajah skematik rawatan haba jahitan kimpalan paip pendek dan siku menggunakan kaedah ciptaan ini.

Pelaksanaan khusus

Kaedah ciptaan ini diperkenalkan di bawah bersempena dengan

Perkenalkan kaedah ciptaan sekarang di bawah bersama dengan lukisan yang disertakan.

Penjelmaan satu:

(1) Balut helaian pemanas elektrik pada kimpalan paip keluli, dan balut kapas penebat di luar lembaran pemanas elektrik;

(2) Seperti yang ditunjukkan dalam Rajah 1, arah yang ditunjukkan oleh anak panah dalam Rajah 1 ditinggalkan. Untuk sambungan kimpalan panjang bahagian paip: jarak antara paip keluli 10 dan lembaran pemanas elektrik 11 dibalut pada kimpalan 12 adalah 550 mm. Lembaran pemanasan elektrik 13 dan lembaran pemanas elektrik yang betul 14, jarak L dari tepi kanan lembaran pemanas elektrik kiri 13 ke tepi kiri lembaran pemanas elektrik 11 adalah 550 milimeter; Tepi kiri helaian pemanas elektrik kanan 14 berada di tepi kanan lembaran pemanas elektrik 11 Jarak L ialah 550 mm; dan paip keluli 10 dibalut sepenuhnya dengan kapas penebat haba aluminium silikat, dan ketebalan kapas penebat haba aluminium silikat adalah 200 mm; di mana, diameter lembaran pemanas elektrik kiri 13 dan lembaran pemanas elektrik yang betul 14 adalah sama dengan paip keluli 10 Bekerjasama, untuk dapat membungkus bulatan jahitan kimpalan paip keluli 10;

(3) Seperti yang ditunjukkan dalam Rajah 2, untuk sambungan kimpalan paip pendek 15 dan siku 16: balut tali pemanas 17 pada siku 16, gunakan kapas penebat aluminium silikat untuk membalut paip keluli sepenuhnya, itu dia, balut paip pendek 15 dan siku Kepala 16 dibungkus sepenuhnya, dan ketebalan kapas penebat aluminium silikat ialah 200 mm;

(4) Mula memanaskan paip keluli. Semasa proses rawatan haba, suhu pada jahitan kimpalan dikawal pada 760°C, dan masa rawatan haba ialah 5 jam; Suhu paip keluli 10 dibalut oleh pemanas elektrik dikawal untuk menjadi 200°C. Gunakan pemanas elektrik yang betul 14 untuk mengawal suhu paip keluli 10 dibalut oleh pemanas elektrik hingga 200°C sehingga rawatan haba tamat; Pemanas elektrik yang dibungkus 11 berada pada jarak 550 mm untuk pampasan suhu, yang mengurangkan pengaruh faktor persekitaran seperti suhu udara dan angin kencang ke atas suhu kimpalan 12 pada jarak 550 mm dari pemanas elektrik 11, memperlahankan suhu paip keluli. 10 kelajuan penyejukan;

Semasa proses rawatan haba, gunakan termometer inframerah untuk mengukur suhu kapas penebat aluminium silikat di 12 tempat-tempat kimpalan. Jika suhu lapisan terluar kapas penebat aluminium silikat lebih tinggi daripada 40°C, balut satu lagi lapisan kapas penebat aluminium silikat. Kapas penebat;

(5) Selepas rawatan haba, suhu jahitan kimpalan menurun kepada 300°C, dan paip keluli 10 dibiarkan sejuk secara semula jadi, dan apabila suhu bulu penebat aluminium silikat turun di bawah 20°C, bulu penebat aluminium silikat telah dikeluarkan.

Penjelmaan dua:

(1) Balut helaian pemanas elektrik pada kimpalan paip keluli, dan balut kapas penebat di luar lembaran pemanas elektrik;

(2) Seperti yang ditunjukkan dalam Rajah 1, arah yang ditunjukkan oleh anak panah dalam Rajah 1 ditinggalkan. Untuk sambungan kimpalan panjang bahagian paip: jarak antara paip keluli 10 dan lembaran pemanas elektrik 11 dibalut pada kimpalan 12 adalah 600 mm. Lembaran pemanasan elektrik 13 dan lembaran pemanas elektrik yang betul 14, jarak L dari tepi kanan lembaran pemanas elektrik kiri 13 ke tepi kiri lembaran pemanas elektrik 11 adalah 600 milimeter; Tepi kiri helaian pemanas elektrik kanan 14 berada di tepi kanan lembaran pemanas elektrik 11 Jarak L ialah 600 mm; dan paip keluli 10 dibalut sepenuhnya dengan kapas penebat haba aluminium silikat, dan ketebalan kapas penebat haba aluminium silikat adalah 220 mm; di mana, diameter lembaran pemanas elektrik kiri 13 dan lembaran pemanas elektrik yang betul 14 adalah sama dengan paip keluli 10 Bekerjasama, untuk dapat membungkus bulatan jahitan kimpalan paip keluli 10;

(3) Seperti yang ditunjukkan dalam Rajah 2, untuk sambungan kimpalan paip pendek 15 dan siku 16: balut tali pemanas 17 pada siku 16, gunakan kapas penebat aluminium silikat untuk membalut paip keluli sepenuhnya, itu dia, balut paip pendek 15 dan siku Kepala 16 dibungkus sepenuhnya, dan ketebalan kapas penebat aluminium silikat ialah 220 mm;

(4) Mula memanaskan paip keluli. Semasa proses rawatan haba, suhu pada jahitan kimpalan dikawal pada 765°C, dan masa rawatan haba ialah 5 jam; Suhu paip keluli 10 dibalut oleh lembaran pemanas elektrik dikawal untuk menjadi 250°C, dan suhu paip keluli 10 dibalut oleh lembaran pemanas elektrik 14 dikawal kepada 250°C dengan menggunakan lembaran pemanas elektrik yang betul 14 sehingga rawatan haba selesai; untuk memperlahankan kadar pelesapan haba paip keluli 10;

Semasa proses rawatan haba, gunakan termometer inframerah untuk mengukur suhu kapas penebat aluminium silikat di 12 tempat-tempat kimpalan. Jika suhu lapisan terluar kapas penebat aluminium silikat lebih tinggi daripada 40°C, balut satu lagi lapisan kapas penebat aluminium silikat. Kapas penebat;

(5) Selepas rawatan haba, suhu jahitan kimpalan menurun kepada 300°C, dan paip keluli 10 dibiarkan sejuk secara semula jadi, dan apabila suhu bulu penebat aluminium silikat turun di bawah 20°C, bulu penebat aluminium silikat telah dikeluarkan.

Penjelmaan tiga:

(1) Balut helaian pemanas elektrik pada kimpalan paip keluli, dan balut kapas penebat di luar lembaran pemanas elektrik;

(2) Seperti yang ditunjukkan dalam Rajah 1, arah yang ditunjukkan oleh anak panah dalam Rajah 1 ditinggalkan. Untuk sambungan kimpalan panjang bahagian paip: jarak antara paip keluli 10 dan lembaran pemanas elektrik 11 dibalut pada kimpalan 12 adalah 750 mm. Lembaran pemanasan elektrik 13 dan lembaran pemanas elektrik yang betul 14, jarak L dari tepi kanan lembaran pemanas elektrik kiri 13 ke tepi kiri lembaran pemanas elektrik 11 adalah 750 milimeter; Tepi kiri helaian pemanas elektrik kanan 14 berada di tepi kanan lembaran pemanas elektrik 11 Jarak L ialah 750 mm; dan paip keluli 10 dibalut sepenuhnya dengan kapas penebat aluminium silikat, dan ketebalan kapas penebat aluminium silikat ialah 250 mm; di mana, diameter lembaran pemanas elektrik kiri 13 dan lembaran pemanas elektrik yang betul 14 adalah sama dengan paip keluli 10 Bekerjasama, untuk dapat membungkus bulatan jahitan kimpalan paip keluli 10;

(3) Seperti yang ditunjukkan dalam Rajah 2, untuk sambungan kimpalan paip pendek 15 dan siku 16: balut tali pemanas 17 pada siku 16, gunakan kapas penebat aluminium silikat untuk membalut paip keluli sepenuhnya, itu dia, balut paip pendek 15 dan siku Kepala 16 dibungkus sepenuhnya, dan ketebalan kapas penebat silikat aluminium ialah 250mm;

(4) Mula memanaskan paip keluli. Semasa proses rawatan haba, suhu pada jahitan kimpalan dikawal pada 770°C, dan masa rawatan haba ialah 5 jam; Suhu paip keluli 10 dibalut oleh lembaran pemanas elektrik dikawal untuk menjadi 300°C, dan suhu paip keluli 10 dibalut oleh lembaran pemanas elektrik 14 dikawal kepada 300°C dengan menggunakan lembaran pemanas elektrik yang betul 14 sehingga rawatan haba selesai; untuk memperlahankan kadar pelesapan haba paip keluli 10;

Semasa proses rawatan haba, gunakan termometer inframerah untuk mengukur suhu kapas penebat aluminium silikat di 12 tempat-tempat kimpalan. Jika suhu lapisan terluar kapas penebat aluminium silikat lebih tinggi daripada 40°C, balut satu lagi lapisan kapas penebat aluminium silikat. Kapas penebat;

(5) Selepas rawatan haba, suhu jahitan kimpalan menurun kepada 300°C, dan paip keluli 10 dibiarkan sejuk secara semula jadi, dan apabila suhu bulu penebat aluminium silikat turun di bawah 20°C, bulu penebat aluminium silikat telah dikeluarkan.

Menggunakan kaedah ciptaan ini mengurangkan pemindahan haba antara jahitan kimpalan dan lembaran pemanas elektrik yang dibalut pada paip keluli pada jarak 550-700 mm dari jahitan kimpalan, dan juga sangat mengurangkan pengaruh suhu udara dan faktor lain pada suhu jahitan kimpalan. Pengaruh, memperlahankan kelajuan pelesapan haba paip keluli, memastikan suhu paip keluli dalam proses rawatan haba, meningkatkan kualiti rawatan haba, gunakan kaedah ciptaan ini untuk menjalankan rawatan haba pada paip keluli, nilai kekerasan jahitan kimpalan adalah kurang daripada atau sama dengan 241HB, memenuhi keperluan spesifikasi ASME. Kaedah ciptaan ini juga menggunakan bahan penebat haba untuk membalut paip keluli sepenuhnya, yang seterusnya mengurangkan pengaruh suhu udara dan faktor lain ke atas suhu kimpalan.

Contoh perbandingan satu

(1) Balut helaian pemanas elektrik pada jahitan kimpalan, dan balut kapas penebat di luar lembaran pemanas elektrik;

(2) Mula memanaskan paip keluli. Semasa proses rawatan haba, suhu pada jahitan kimpalan dikawal pada 765° C., dan masa rawatan haba ialah 5 jam.

Jadual 1 di bawah adalah perbandingan data nilai kekerasan pada kimpalan selepas kaedah rawatan haba Contoh Perbandingan 1 dan kaedah Contoh 1, contoh 2 dan Contoh 3 selesai.

Jadual 1

Ia boleh disimpulkan daripada Jadual 1 bahawa paip keluli dirawat haba menggunakan kaedah Contoh Perbandingan 1. Selepas rawatan haba selesai, 5 mata dipilih pada kimpalan. Nilai kekerasan bagi 5 mata ialah 299HB, 311HB, 317HB, 291HB, 294HB, dan 5 Nilai kekerasan mata semuanya lebih besar daripada 241HB, yang tidak dapat memenuhi keperluan standard ASME; menggunakan kaedah penjelmaan dua, selepas rawatan haba selesai, 5 mata dipilih pada kimpalan, dan nilai kekerasan bagi 5 mata masing-masing 200HB, 215HB, 218HB, dan 222HB , 217HB, nilai kekerasan 5 mata semuanya kurang daripada 241HB, yang memenuhi keperluan spesifikasi ASME; menggunakan kaedah penjelmaan 1 dan penjelmaan 3, nilai kekerasan kimpalan selepas rawatan haba juga semuanya kurang daripada 241HB, yang memenuhi keperluan spesifikasi ASME.

-steel-pipe.jpg)