senarai pembelian Tehran kontraktor – paip keluli lancar Spesifikasi

April 3, 2018

Ini Grace daripada keluli ABTER di China. kami pakar dalam paip keluli 2018.03.26

April 6, 2018ASTM A179 (ASME SA179) Penerangan Paip

Sejuk disediakan lancar tiub keluli karbon untuk penukar haba dan kondenser

Saiz (mm): O.D.:6.0~ 114.0; W.T.:1~ 15; L: maksimum 12000

Penerangan:

1. Piawaian: ASTM A179 (ASME SA179)

2. aplikasi: Penukar haba, condensers, peralatan pemindahan haba dan paip sama.

3. gred: A 179

4. Spesifikasi: Diameter 10.3 kepada 76.2 mm; ketebalan: 1.2 kepada 12 mm; panjang: 6 m dan ke atas; dan, spesifikasi diubahsuai mengikut keperluan pelanggan.

5. Komposisi kimia dan sifat mekanikal.

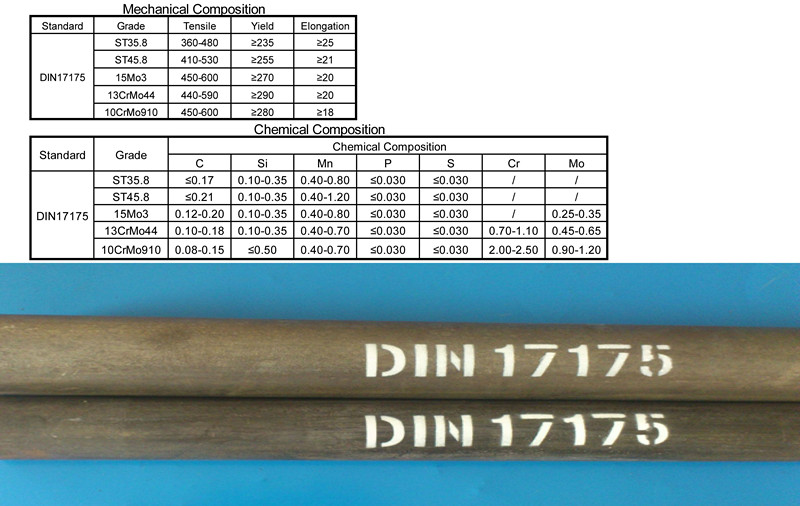

DARIPADA 17175 Aloi paip Penerangan

Standard: DARIPADA 17175

Kami boleh membekalkan pelbagai gred lancar paip dandang, seperti St35.8, St45.8, 15Mo3, 13CrMo44, 10CrMo910, dan lain-lain.

Saiz RangeThe pelbagai saiz JST keluli lancar dandang tiub adalah seperti berikut:

dimensi luar adalah dari 6.0 mm untuk 219.0 mm.

ketebalan dinding DIN 17175 lancar julat paip dandang dari 1 mm untuk 30 mm.

Panjang maksimum ialah 12 m.

Ini paip dandang lancar juga boleh digunakan sebagai paip pemanasan permukaan, economizer, Pemanas lampau, pemanas semula dan paip industri petrokimia untuk dandang tekanan tinggi (Tekanan kerja di atas memburu for.8 Mpa secara umum dan suhu kerja adalah antara 450 ℃ 650 ℃. ).

ASTM A179 (ASME SA179) Paip Komposisi Kimia:

| Komposisi kimia | C | MN | P≤ | S≤ | Si≤ |

| 0.06-0.18 | 0.27-0.63 | 0.035 | 0.035 | 0.25 |

DARIPADA 17175 Aloi paip Komposisi Kimia:

|

gred |

Komposisi kimia (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | Si | MN | P | S | Ni | TK | MO | lain-lain | |

| St35.8 | 0.17Max | 0.10~ 0.35 | 0.40~ 0.80 | 0.040Max | 0.040Max | – | – | – | – |

| St45.8 | 0.21Max | 0.10~ 0.35 | 0.40~ 1.20 | 0.040Max | 0.040Max | – | – | – | – |

| 17MN4 | 0.14~ 0.20 | 0.20~ 0.40 | 0.90~ 1.20 | 0.040Max | 0.040Max | – | 0.30Max | – | – |

| 19Mn5 | 0.17~ 0.22 | 0.30~ 0.60 | 1.00~1.30 | 0.040Max | 0.040Max | – | 0.30Max | – | – |

| 15Mo3 | 0.12~ 0.20 | 0.10~ 0.35 | 0.40~ 0.80 | 0.035Max | 0.035Max | – | – | 0.25~ 0.35 | – |

| 13CrMo910 | 0.10~ 0.18 | 0.10~ 0.35 | 0.40~ 0.70 | 0.035Max | 0.035Max | – | 0.70~ 1.10 | 0.45~ 0.65 | – |

| 10CrMo910 | 0.08~ 0.15 | 0.50Max | 0.40~ 0.70 | 0.035Max | 0.035Max | – | 2.00~ 2.50 | 0.90~ 1.20 | – |

| 14MoV63 | 0.10~ 0.18 | 0.10~ 0.35 | 0.40~ 0.70 | 0.035Max | 0.035Max | – | 0.30~ 0.60 | 0.50~ 0.70 | V: 0.22~ 0.32 |

| X20CrMoV121 | 0.17~ 0.23 | 0.50Max | 0.40~ 0.70 | 0.030Max | 0.030Max | 0.30~ 0.80 | 10.00~ 12.50 | 0.80~ 1.20 | V: 0.25~ 0.35 |

ASTM A179 (ASME SA179) Paip Mechanical Hartanah:

| Keluli gred | Kekuatan Hasil (MPa) | Kekuatan tegangan (MPa) | Elongation (%) |

| ASTM A179 | ≥180 | ≥325 | ≥35 |

Properties mekanikal lancar DIN 17175Boiler Paip:

|

gred

|

barangan nombor |

Tegangan Test MPa atau N / mm2

|

serpihan ditayangkan(Sama dengan JIS) |

kemungkinan suhu

|

||

|

titik Min Hasil |

Kekuatan tegangan |

|||||

| t 16Max | 16<t 40Max | |||||

|

St35.8

|

1.0305

|

235

|

225

|

360~ 480

|

Ujian kesan di Bilik Temp.kgf-m (STPT38) |

|

|

St45.8

|

1.0405

|

–

|

245

|

410~ 530

|

23.5(STPT410, STB410)

|

|

|

17MN4

|

1.0481

|

–

|

275

|

460~ 580

|

22.8

|

|

|

19Mn5

|

1.0482

|

–

|

315

|

510~ 610

|

23.5(STB52)

|

|

|

15Mo3

|

1.5415

|

275

|

275

|

450~ 600

|

23.5

|

|

|

13CrMo910

|

1.7335

|

295

|

295

|

440~ 590

|

23.2(STPA22, STBA22)

|

|

|

10CrMo910

|

1.7380

|

285

|

285

|

450~ 600

|

23.2(STPA24, STBA24)

|

|

|

14MoV63

|

1.7715

|

325

|

325

|

460~ 610

|

24.2

|

|

|

X20CrMoV121

|

1.4922

|

490

|

490

|

690~ 850

|

23.5

|

|

Dimensi Tiub Lancar ASTM A179:

| OD (mm) | Ketebalan dinding (mm) | |||||||||||||

| 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 6 | 6.5-7 | 7.5-8 | 8.5-9 | 9.5-10 | 11 | 12 | |

| Φ25-Φ28 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ32 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ34-Φ36 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ38 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ40 | ● | ● | ● | ● | ● | |||||||||

| Φ42 | ● | ● | ● | ● | ● | |||||||||

| Φ45 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ48-Φ60 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ63.5 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ68-Φ73 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ76 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ80 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ83 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ89 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ95 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ102 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ108 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ114 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ121 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ127 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ133 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ140 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ146 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ152 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ159 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ168 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

SA-450/ SA - 450M:

| OD dalam (mm) | + | – | WT di (mm) | + | – |

| <1(25.4) | 0.10 | 0.10 | ≤1.1 / 2(38.1) | 20% | 0 |

| 1∼1.1 / 2(25.4∼38.1) | 0.15 | 0.15 | >1.1/2(38.1) | 22% | 0 |

| >1.1/2∼<2(38.1∼50.8) | 0.20 | 0.20 | |||

| 2∼<2.1/2(50.8∼63.5) | 0.25 | 0.25 | |||

| 2.1/2∼<3(63.5∼76.2) | 0.30 | 0.30 | |||

| 3∼4(76.2∼101.6) | 0.38 | 0.38 | |||

| >4∼7.1 / 2(101.6∼190.5) | 0.38 | 0.64 | |||

| >7.1/2∼9(190.5∼228.6) | 0.38 | 1.14 |