Yeni Bir Teknoloji: A335 Alaşımlı Çelik Boru Kaynak Derz Isıl İşlem

Mayıs ayı 23, 2023

ASTM A105 ve ASTM A234 arasındaki fark nedir?

Haziran 18, 2023ABTER STEEL'in HFW yağ muhafazasının gelecekteki araştırma ve geliştirme beklentileri tartışılmaktadır. ABTER STEEL HFW yağ muhafazasının geliştirilmesinin çelik üretimini vurgulaması gerektiğine dikkat çekilmektedir + boru yapımı + boru işleme

ve farklılaştırılmış gelişime ulaşmak için tutarlı kalite sisteminin avantajları; geliştirilen ürünlerin özelliklerini ve çıktılarını genişletmek, geniş çaplı, kalın duvarlı K55'i araştırın ve geliştirin, yüksek anti-ekstrüzyon ve korozyon direnç

Yağ Muhafazası.

Anahtar kelimeler: HFW; yağ mahfaza; ABTER ÇELİK; araştırma ve geliştirme durumu; olasılık; J55; K55

Şekillendirme yöntemine göre, yağ muhafaza boruları iki tipe ayrılır: dikişsiz çelik borular ve kaynaklı borular. Dikişsiz çelik borularla karşılaştırıldığında, Kaynaklı borular, yüksek et kalınlığı ve boyut doğruluğu gibi en dikkat çekici özelliklere sahiptir, iyi çökme direnci, ve kısa üretim süreci. , yüksek üretim verimliliği, geniş spesifikasyon yelpazesi, enerji tasarrufu, düşük üretim maliyeti, ve yüksek maliyet performansı; bu nedenle, yüksek frekanslı kaynak (Kısaca HFW) yabancı ülkelerde petrol muhafazalarında yaygın olarak kullanılmaktadır (Amerika Birleşik Devletleri gibi, Almanya, Japonya, Güney Kore, vb.) ) dikişsiz çelik borular yerine borular, yerli petrol sahaları da yavaş yavaş petrol kullanımını teşvik ediyor [1]

.

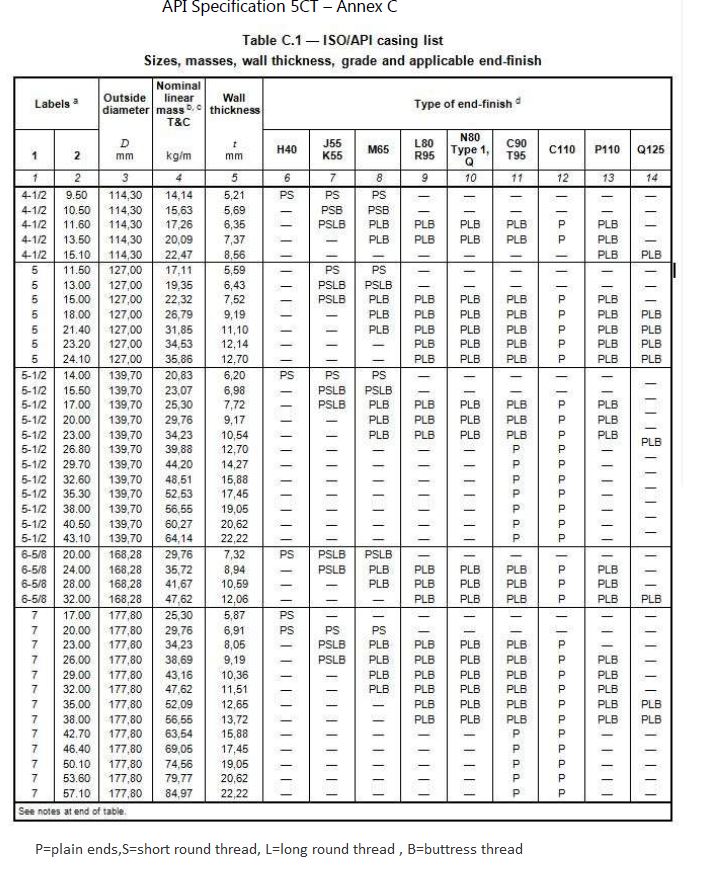

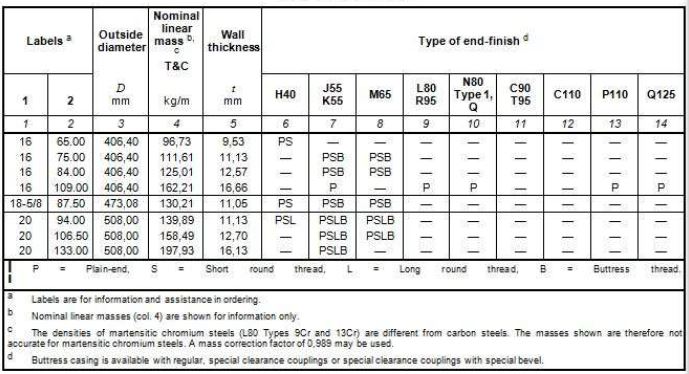

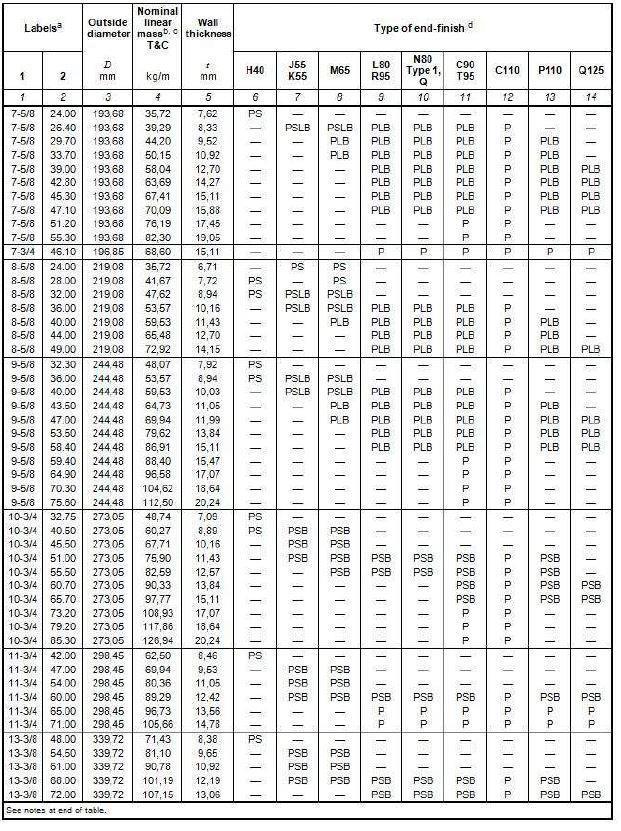

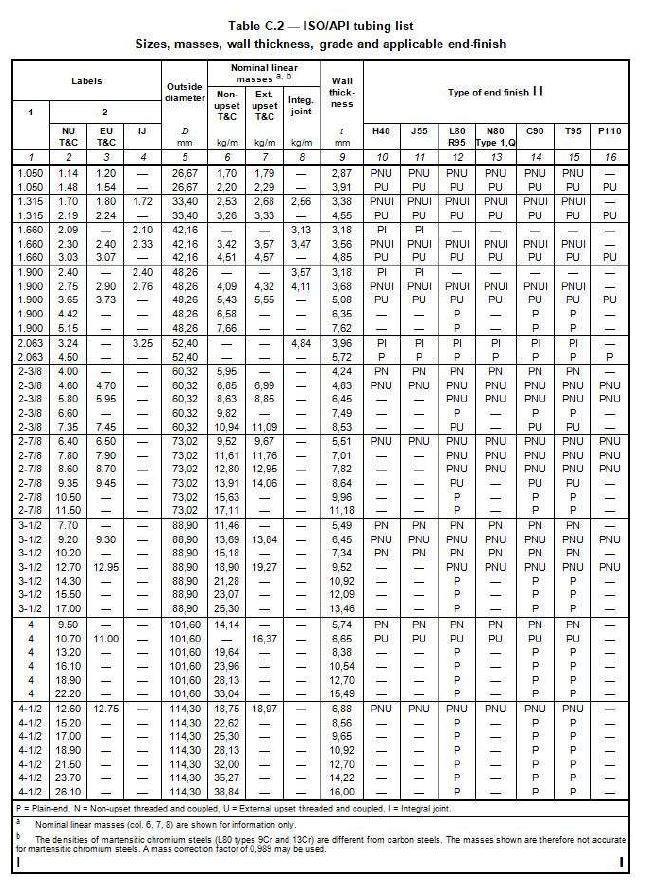

ABTER ÇELİK A.Ş., Ltd. (Kısaca ABTER ÇELİK) H40'ı geliştirdi, J55, K55,

M65, L80 -1, N80-Q, N80 -1 ve P110 çelik sınıfı HFW yağ muhafaza ürünleri, dahil olmak üzere 7 dış çaplar (219.08 ~508.00mm), 46 özellikler (Tablo 1), temel olarak ürün taslağını karşılayın Gereksinimlere göre, 500,000 Tonlarca yerli ve yabancı petrol sahalarına ve diğer kullanıcılara tedarik edildi [2-3].

API 5CT Gr.J55 Boru Muhafazası

API 5CT-Amerikan Petrol Enstitüsü dikişsiz kasa ve borulara yönelik spesifikasyondur, API 5CT J55 Kasa boru esas olarak sığ kuyular için kullanılır, Jeotermal kuyu, ve su kuyuları veya petrol kuyusu sondajları, sondaj işleminin ve tamamlandıktan sonra tüm kuyunun normal çalışmasını sağlamak için esas olarak sondaj sırasında ve sonrasında kuyu duvarını desteklemek için. Dünya demiri & Steel, Çin'in önde gelen Muhafaza Borusu üreticilerinden ve tedarikçilerinden biridir, Yüksek kaliteli API J55 muhafaza borusu satın almak veya ithal etmek istiyorsanız, bizimle iletişime geçmekten kaçınmayın.

Standart: API 5CT

Sınıf: J55

Tolerans.

Dış Çap <114,3 mm tolerans ±0,79

OD≥114,3mm tolerans -0.5% +1%

Kalınlık toleransı:-12.5%

Uygulamalar: Sığ kuyular, Jeotermal kuyu, ve su kuyuları veya diğer petrol kuyuları

J55 Muhafazanın Teknik Zorlukları ve Proses Özellikleri

Diğer kaynak yöntemleriyle karşılaştırıldığında, yüksek frekanslı kaynak, metal dolgu maddelerinin bulunmaması ile karakterize edilir (kaynak teli gibi); bu nedenle, kaynak işlemi stabil olduğunda, kaynak kalitesi büyük ölçüde çelik şeridin kalitesine bağlıdır. Örneğin, Baosteel'in Φ610 mm HFW boyuna dikişli kaynaklı boru ünitesi tarafından üretilen J55 muhafaza, ana güçlendirme elemanları olarak C ve Mn içeren orijinal bir çelik kimyasal bileşimine sahiptir., Nb içermiyor, ve sıcak haddelenmiş çelik şeritte merkezi ayırmaya sahiptir [1 ]

.

J55 yağ muhafazasının üretilebilecek aralığı Ф219,08~508,00 mm'dir., Ф219,08 mm ve Ф244,48 mm'lik iki spesifikasyon için kullanılan çelik bant genişlikleri şunlardır: 700 mm ve 770 sırasıyla mm, hangileri dar şeritlerdir. Sıcak haddeleme kapasitesinin boşa gitmemesi için, Genellikle sıcak haddelenmiş 1 420 mm, 1 560 mm genişliğinde şeritler merkez çizgisi boyunca uzunlamasına kesitlere sahiptir. Sıcak haddelenmiş çelik şeridin bileşim ayrımı nedeniyle, ve ayrıştırılması 1/2 parça (çelik şeridin merkezi) ciddi, merkez ayırma bölgesi boru yapıldıktan sonra kaynakta bulunur, ve çevrimiçi kaynak normalleştirme ısıl işleminden sonra kaynak ısısından etkilenen bölgedeki ayrışma bölgesi Gövde üzerinde martensit şeritleri var, ve API standartları, muhafazada temperlenmemiş martensit varlığına izin vermez, bu yüzden eklemek gerekiyor

Ortadan kaldırmak için tüm tüp ısıl işlemini ekleyin, dolayısıyla üretim maliyetini arttırmak. Yukarıdaki sorunlara yönelik, ABTER ÇELİK A.Ş., Ltd. J55 muhafaza için kullanılan çelik şeridin kimyasal bileşimini ayarlamak için iki test şeması tasarladı[1]

.

Şema 1: Çelik şerit merkezinde ayrışmayı azaltmak için malzeme tasarımında karbonu azaltın, w (C) olduğu 0.17% için 0.20%, 0.075% orijinal kimyasal bileşimden daha düşük, karbon ayrışmasının azaltılması; Si, Mn içeriği ve orijinal kompozisyon aynı. Planın deneme üretiminden sonra 1, çelik şeridin ortasındaki ayrışma azalır, ancak kaynak normalleştirme ısıl işleminden sonra ısıdan etkilenen bölgedeki ayrışma bölgesinde hala az miktarda martenzit var[1]

.

Şema 2: Çelik şerit merkezinde ayrışmayı azaltmak için malzeme tasarımında karbon ve manganezi azaltın, w (C) olduğu 0.13% için 0.18%, hangisi 0.105% orijinal kimyasal bileşimden daha düşük, karbon ayrışmasının azaltılması; w (MN) %0,60~%1,00, hangisi 0.30% orijinal kimyasal bileşimden daha düşük, manganezin ayrışmasını azaltır, böylece kaynakta çevrimiçi normalleştirme ısıl işlemi sonrasında martensitik yapı oluşmaz.[1]; güç kaybı, Borunun işleme performansını artırın ve mahfaza dişinin yapışmasını önleyin; erimiş çeliği saflaştırmak için az miktarda Ca ekleyin, MnS'nin küreselleşmesini teşvik etmek, ve malzemenin kapsamlı performansını iyileştirin [4]. Şemanın bileşimine göre tasarlanan J55 çelik şerit için 2, Boru yapımından sonra kaynağın ısıdan etkilenen bölgesinde martenzit oluşmayacak, ve mikro yapı ve güç, API Spec 5CT gereksinimlerini karşılıyor.

API 5CT K55/J55 Kimyasal Bileşimi

| Sınıf | C≤ | Si≤ | Mn≤ | p≤ | S≤ | CR≤ | Ni≤ | Cu≤ | Mo≤ | V≤ |

| API 5CT K55/J55 | 0.34-0.39 | 0.20-0.35 | 1.25-1.50 | 0.020 | 0.015 | 0.15 | 0.20 | 0.20 | / | / |

API 5CT K55/J55 Mekanik Özellik

| Çelik sınıf | Verim gücü (MPA) | Çekme dayanımı (MPA) | Yük Altında Toplam Uzama % |

| API 5CT K55 | 379-552 | ≥655 | 0.5 |

| API 5CT J55 | 379-552 | ≥517 | 0.5 |

Isıl işlem (PSL2 ve PSL1 farklıdır)

API 5CT J55 PSL1 ve API 5CT K55 PSL2 aynıdır (Devamlı teslimat);

PSL2 :J55 ve K55 normalleştirilmeli veya normalleştirilmeli ve temperlenmelidir. Kalınlaştırılmışsa, normalleştirme veya normalleştirme ve temperleme, koyulaştırmadan sonra eklenmelidir.

Çarpma testi (PSL2 ve PSL1 farklıdır)

Boru: PSL1, J55 ve K55'in herhangi bir zorunluluğu yoktur; PSL2 J55 ve K55, tam boyutlu numune için minimum darbe çalışması 20J gerektirir, ve tam boyutlu numunenin minimum darbe çalışması 27J.

Kaplin: J55 ve K55 darbe testleri gereklidir. Numunenin minimum darbe enerjisi 20J'dir, ve tam boyutlu numunenin minimum darbe enerjisi 27J'dir.

K55 kasasının teknik zorlukları ve proses özellikleri

K55 çelik kalite yağ muhafazasının akma dayanımı aralığı 379-552MPa arasındadır., ve çekme mukavemeti 655MPa'dan büyüktür, malzemenin çok düşük verim oranı ile karakterize edilir (0.58-0.84). Malzemelerin kimyasal bileşiminden tasarlandı

Başka bir deyişle, yaygın karbon-manganez çelikleri düşük verim oranlarına ulaşmak için idealdir, 37Mn5 çeliği gibi, K55 kalite dikişsiz çelik boruların üretiminde yaygın olarak kullanılmaktadır., w ile(C) hakkında 0.37% ve w(MN) hakkında 1.3%. Haddelemeden sonra 37Mn5'in akma mukavemeti yaklaşık 450 MPa, çekme mukavemeti yukarıda 700 MPa, ve verim oranı 0.64, K55 çelik sınıfı mekanik özelliklerin gereksinimlerini karşılayabilen[5]

HFW kasasının üretim süreci: çelik üretimi → sürekli döküm → bobinlere sıcak haddeleme → bobinlerin baş ve kuyruk kesme alın kaynağı → şerit şekillendirme → kaynak → tüm borunun çevrimiçi kaynak ısıl işlemi veya ısıl işlemi → boru işleme → fabrika incelemesi beklemesi. Bobin başı ve kuyruk kesme alın kaynağı işlemi, birden fazla bobinin sürekli üretimini gerçekleştirmek ve HFW kaynaklı boruların üretim verimliliğini yansıtmak için temel süreçtir.. ancak, Bobinlerin baştan sona alın kaynağı için gerekli malzemelerin düşük karbon eşdeğeri nedeniyle, Genellikle karbon eşdeğeri CEIIW'nin şu değerlerden daha az olması gerekir: 0.43, aksi takdirde şerit kırılmasına neden olmak ve üretim verimliliğini ciddi şekilde etkilemek kolaydır. 37Mn5 çeliğin karbon eşdeğeri CEIIW'ye ulaştığından beri 0.58, kaynaklı boruların üretim süreci özellikleriyle birlikte, Bu çeliğin K55 çelik sınıfı HFW yağ muhafazasının üretimi için uygun olmadığı açıktır.; bu nedenle, K55 çelik sınıfı HFW yağ mahfazasının üretimindeki teknik zorluk, malzemede yatmaktadır. Tasarım, düşük karbon eşdeğerinde düşük bir verim oranı sağlamalıdır.. ABTER STEEL Co.'nun HFW oluşturma yöntemi., Ltd. gelişmiş sıralı rulo şekillendirme teknolojisini benimser, mükemmel kaynak performansı elde etmek için garanti sağlar. şekillendirme işlemi sırasında, çelik şerit her haddehanenin merdanelerinden geçer, ve tasarlanan geçiş sistemine göre kademeli olarak ideal tüp boşluğunun şekline bükülür [3], sürekli ve dinamik bir deformasyon sürecidir. bu süreçte, çelik şeridin enine bükülme deformasyonu ile birlikte, gerginlik, sıkıştırma ve geri yaylanma aynı anda meydana gelir, Plakanın yüzeyinde ve kalınlık yönünde kayma deformasyonu, ve kenarda uzunlamasına gerilme ve ekstrüzyon deformasyonu [6]. Çeşitli deformasyonların stres durumu çok karmaşıktır, ancak ε gerinimi aşağıdaki formülle tahmin edilebilir: ε=t/(D+t) (1) nerede t——çelik şeridin kalınlığı, mm; D——kaynaklı borunun dış çapı, mm . Uygulama şunu kanıtladı: karbon azaltımı yoluyla, Sıcak haddeleme sırasında alaşımlama ve kontrollü soğutma, mekanik özellikleri K55 çelik sınıfının gerekliliklerini karşılayan sıcak haddelenmiş rulolar üretmek mümkündür. Örneğin, Nihai haddeleme sıcaklığı daha yüksek olan sıcak haddelenmiş bir rulo için 860 °C ve sarma sıcaklığı 570 ° C, akma gücü 478 MPa ve çekme mukavemeti 697 MPa [5]. Orta çaplı Ф273 mm×10,16 mm kasa için, boru yapımından sonraki gerilim yaklaşık 3.6%. Gerilme-gerinim eğrisine göre, ne zaman zorlanma 3.6% oluşur, Boru yapımından sonra akma dayanımı yaklaşık 563 MPa, K55 çelik sınıfının gerekli akma dayanımı aralığını aşan [5]. Bu tür sıcak haddelenmiş rulo için, Boru yapımından sonra akma dayanımının daha az olmasını sağlamak için 552 MPa, boru yapımından sonraki gerinim aşılmamalıdır 3.0%. K55 çelik sınıfının farklı özelliklerine sahip HFW kasası aşağıdakilerle sınırlıysa: 3.0% gerilmek, yalnızca Ф339,72 mm×9,65 mm vardır, Ф406,4 mm×11,13 mm, Ф473,08 mm×11,05 mm, Ф508mm×12,7mm, Ф508 mm × 11,13 mm ve HFW burçların diğer spesifikasyonları daha az bir gerilime sahiptir. 3.0%, yani, Bobinlerin performans dalgalanmalarının dikkate alınmadığı ideal koşullar altında, kasaların yalnızca yukarıdaki beş özelliği Boru yapımından sonraki mekanik özellikler K55 çelik sınıfının gereksinimlerini karşılayabilir. Diğer spesifikasyonlardaki muhafazalar için, Nitelikli HFW muhafazaları üretmek için boru yapımından sonra ısıl işlem kullanılmalıdır.

Yerinde üretim, bobin ile karşılaştırıldığında şunu göstermektedir:, Boru gövdesinin şekillendirme sonrasında akma mukavemeti yaklaşık olarak 50-100 MPa bobininkinden daha yüksek, ve çekme mukavemeti yaklaşık 10-30 MPa daha düşük. Böylece, ideal bobin akma dayanımı kontrol edilmelidir

400MPa civarındadır, çekme mukavemeti 680MPa'nın üzerinde kontrol edilmelidir; verim oranı 0.59. Açıkça, sıradan karbon veya düşük alaşımlı çelik için bu kadar düşük bir akma oranına ulaşmak zordur.

Uygulama şunu gösterdi: küçük çaplı HFW muhafazanın kayda değer iş sertleştirme etkisi nedeniyle, Sıcak haddelenmiş levhanın sarma işleminden sonraki mekanik özellikleri K55 çelik sınıfının gereksinimlerini karşılayamıyor. ancak, Büyük çaplı kasanın işlenme sertleştirme etkisi aynı duvar kalınlığında küçüktür. Laboratuvar araştırmalarına dayanarak, bununla başa çıkmak için sırasıyla iki takım teknik çözüm benimsenebilir. Planı 1, Ф339 mm'nin üzerindeki özellikler, Mevcut çelik kalitelerinin kimyasal bileşimi üzerinde ince ayar testleri yapmak, boru imalatından sonra on-line kaynak ısıl işlemi ile kaliteli K55 çelik kalite kasa üretmek amacıyla; Planı 2, Ф339 mm'nin altındaki özellikler, boru yapımını geçtikten sonra Tüm borunun normalleştirme ısıl işlemi, K55 çelik sınıfının performans gereksinimlerini karşılar.

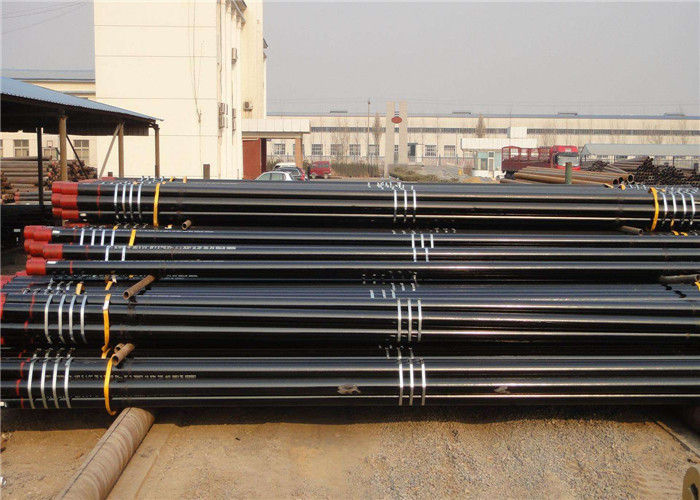

İlk şema grubu için, kompozisyon tasarımı fikri: iki katı çözelti güçlendirici alaşım elementinin en iyi kombinasyonu, C ve Mn, malzemenin akma mukavemeti oranını etkili bir şekilde azaltabilir [7], K55 çelik kalitesinin üretimi için 37Mn5 çelik kalitesi gibi dikişsiz çelik boru , ve akma dayanımı oranı ulaşabilir 0.64; bu nedenle, Düşük karbon eşdeğeri ve düşük akma dayanımı oranı gerekliliklerini karşılamak için karbon 37Mn5 bazında azaltılır. Diğer yandan, alüminyumla öldürülmüş çelik, geleneksel ince taneli bir çeliktir, ve Al alaşım elementi olarak kullanılır. Malzemenin akma dayanımı oranının düşürülmesi sakıncalıdır., ve Al içeriği azaltılmalıdır. İkinci şema grubu için, Kaynaklı boruya ısıl işlemin normalleştirilmesi yöntemi, şerit oluşumundan kaynaklanan iş sertleşmesi etkisini ortadan kaldırmak için kullanılır. Çünkü kaynaklı borunun normalleştirici ısıl işlemi yalnızca malzemenin iş sertleşmesinin etkisini ve bobinin kendi özelliklerindeki dalgalanmanın mekanik özellikler üzerindeki etkisini ortadan kaldırmakla kalmaz, aynı zamanda kaynak dikişinin mekanik özelliklerini ve mikro yapısını boru gövdesine yakın hale getirir, ve tüm borunun mekanik özellikleri stabildir. iyi seks. Kompozisyon tasarım fikri aşağıdaki gibidir: karbon-manganez çeliği temelinde, V ana güçlendirici unsurdur, P ve S gibi safsızlıklar kontrol edilir, ve erimiş çelik Ca muamelesi ile saflaştırılır. İstikrarlı performansa sahip K55 çelik sınıfı kasa. Boru yapımından sonraki iki şemanın çekme özellikleri, API Spec 5CT standardının gereksinimlerini karşılıyor (Tablo 2). Ф473.08 mm×11.05 mm K55 çelik kalite kasa ürünleri Şekilde gösterilmektedir. 1.

ABTER STEEL HFW yağ muhafazasının geliştirme beklentisi

Literatüre göre [8], petrol ve yanıcı gazlar (doğal gaz gibi, kaya gazı, kömür yatağı metan, vb.) Şu anda insanların tükettiği ana enerji. Geçmişte 30 yıl, dünyanın fosil enerji kullanımı artmaya devam etti, esas olarak petrolden, yanıcı gaz ve kömür. Diğer enerji türleri, su enerjisi gibi, nükleer enerji, biyokütle enerjisi, rüzgar enerjisi, ve güneş enerjisi, toplam enerjinin yalnızca küçük bir kısmını oluşturur. En iyimser gelişme hızında bile, Fosil enerjiyi değiştirmek ve en azından öncesinde hakim bir konuma sahip olmak imkansızdır. 2050 . Ülkem net petrol ithalatçısı haline geldiğinden beri 1993, ülkemin ham petrol tüketimi yıllık ortalama 5.77%, dünyanın en büyük ikinci ham petrol tüketicisi haline geldi. Uluslararası Enerji Ajansı'nın tahminlerine göre (IEA) ve ABD Enerji Bilgi İdaresi (ÇED), İle 2030, ülkemin petrol ve gaz talebi temel olarak yaklaşık 800 milyon ton ham petrol ve yaklaşık 200 milyar m3 doğal gaz. Çin “On İkinci Beş Yıllık Plan” petrol ve gaz eşdeğeri planları: Çin Ulusal Petrol Şirketi'nin 400 milyon ton, bunların arasında denizaşırı keşifler de yer alıyor 50%, yerli anahtar madenciliği Songliao, Sürüler, Sincan, Bohai Körfezi ve Sichuan-Chongqing bölgeleri; Çin Petrokimya Şirketi'nin planları Üretim eşdeğeri 110 milyon ton; Çin Ulusal Offshore Petrol Şirketi'ninki 100 milyon ton. Sırasında “On İkinci Beş Yıllık Plan” dönem, Petrol kuyusu borularına yönelik ortalama yıllık talep yaklaşık 3.2 milyon ton. Petrol kuyusu boruları, petrol ve gaz arama ve geliştirme için gerekli olan önemli malzeme ve ekipmanlardır., ve ortalamayı hesaplıyoruz 20% için 30% tüm kuyu inşaatı maliyetinin. Petrol ve gaz endüstrisi arama ve geliştirme süreci, petrol kuyusu borularının büyük miktarlarda kullanılması ve tüketilmesi sürecidir.. 1980'lerden önce, Ülkemde kullanılan petrol kuyusu borularının tamamı veya büyük bir kısmı ithalata dayalıydı. Değin 1998, ülkemdeki petrol kuyusu borularının yerlilik oranı ulaştı 85% [9]. Şu anda, ülkemin petrol kuyusu boru üretim kapasitesi ulaştı 10 milyon ton, ve üretim kapasitesi ciddi şekilde aşırı kapasitededir. Aralarında, çelik üretimi yapan işletmelerin üretim kapasitesi + boru yapımı + boru işleme yetenekleri yaklaşık 5.5 milyon ton, Tianjin Çelik Boru Group Co. gibi, Ltd., ABTER ÇELİK, Hengyang Valin Çelik Boru A.Ş., Ltd., Pangang Grubu Chengdu Çelik Vanadyum A.Ş., Ltd., Wuxi Simlais Petroleum Özel Boru İmalat A.Ş., Ltd., vb.; boru üretimi yapan firmalar + boru işleme yetenekleri yaklaşık 1.3 milyon ton, Baoji Petroleum Steel Pipe Co. gibi., Ltd.; Boru işleme kapasitesine sahip işletmelerin üretim kapasitesi yaklaşık 3.2 milyon ton, çeşitli petrol sahası işleme işletmeleri gibi.

Ülkemdeki petrol kuyusu borularının ciddi kapasite fazlası nedeniyle, ABTER STEEL HFW yağ muhafazasının geliştirilmesi çelik üretiminin avantajlarını vurgulayacaktır + boru yapımı + boru işleme ve tutarlı kalite sistemi, farklılaştırılmış gelişim, ve aşağıdaki konularda çalışmalar yürütmek:

(1) Düşük basınçta ekonomik yağ muhafazası talebini karşılamak için H40 çelik sınıfı yağ muhafazasının özelliklerini ve çıkışını genişletin, düşük geçirgenliğe sahip petrol ve gaz alanları.

(2) M65'in özelliklerini ve çıktısını genişletin, L80-1, Maliyetleri azaltmak ve verimliliği artırmak amacıyla petrol sahalarının ihtiyaçlarını karşılamak için N80-Q ve P110 çelik sınıfı yağ muhafaza boruları.

(3) Belirli dış pazarların ihtiyaçlarını karşılamak için geniş çaplı, kalın duvarlı K55 çelik sınıfı yağ muhafazasını araştırın ve geliştirin.

(4) Ekstrüzyon önleyici yüksek yağ muhafazasını araştırın ve geliştirin, 80-TT gibi, Petrol sahalarında ekonomik, yüksek ekstrüzyon önleyici kasa talebini karşılamak için.

(5) Korozyona dayanıklı petrol muhafazasını araştırın ve geliştirin, 80S gibi, 90S ve 95S, Petrol sahalarında ekonomik, korozyona dayanıklı muhafaza talebini karşılamak için.

-steel-pipe.jpg)