Siku saluran paip keluli karbon berdasarkan arus eddy medan jarak jauh

September 20, 2025

Topi paip keluli karbon

September 26, 2025Asas perindustrian nikel tulen: Nikel 200 (UNS N02200) Tiub aloi – Gambaran Keseluruhan Komprehensif

Chapter I: Pengenalan -Definisi, Status sejarah, dan nilai teras nikel tulen secara komersial

1.1 Kepentingan nikel murni komersial dan genesis nikel 200

Dalam persekitaran pengeluaran perindustrian yang sangat khusus dan menuntut hari ini, material performance requirements extend far beyond basic mechanical strength. When facing aggressive chemical kakisan, specialized electrical/thermal needs, and stringent product purity standards, ordinary metallic materials often prove inadequate. It is in this context that Nickel-Base Alloys, khususnya Nikel 200 (UNS N02200), renowned as “Commercially Pure Nickel,” have established themselves as an indispensable foundation for numerous critical industrial processes, thanks to their unique combination of high chemical purity and outstanding properties.

Nikel 200 is not a new innovation; its history traces back to the 1930s, initially developed by the former International Nickel Company (Inco). It represents one of the highest purity nickel alloys commercially available, typically requiring a nickel content of tidak kurang daripada \(99.0\%\). This exceptional purity endows it with a unique set of physical and chemical characteristics, notably its unmatched stability and resistance to corrosion in aggressive caustic alkaline media—a position it holds unyieldingly in the critical chemical processing sector.

Our company specializes in the R&D and manufacture of Nikel 200 / UNS N02200 Nickel Alloy Tiub. As a critical component for fluid transfer, heat exchange, dan sokongan struktur, the quality of our tubing directly determines the reliability and service life of the entire system. We recognize that manufacturing a compliant Nickel 200 tube is not merely a metal forming process; it is a systemic undertaking involving metallurgy, precision machining, ujian bukan pemusnah (NDT), and stringent quality control. We provide more than just metal tubes; we offer a long-term commitment to industrial continuity, product purity, dan keselamatan, rooted in a deep understanding of materials science and an uncompromising pursuit of manufacturing excellence.

1.2 Key Technical Distinction: Nikel 200 Vs. Nikel 201 and the Temperature Boundary

Before delving into the performance specifics of Nickel 200, it is crucial to clarify the significant difference between it and its lower-carbon counterpart, Nikel 201 (UNS N02201). This distinction represents a vital technical criterion for alloy selection:

- Nikel 200 (UNS N02200): Carbon content is controlled up to a maximum of \(0.15\%\).

- Nikel 201 (UNS N02201): Carbon content is strictly controlled to be di bawah \(0.02\%\).

This seemingly minor difference in carbon content leads to a major divergence in application performance: Nikel 200 is susceptible to graphitization or sensitization (intergranular carbide precipitation) when exposed to temperatures exceeding \(315^ circ text{C}\) (\(600^ circ text{F}\)) for extended periods, which increases its sensitivity to intergranular corrosion. Oleh itu, **Nikel 200 is primarily recommended by metallurgical engineers for service environments below \(315^ circ text{C}\)**.

Nikel 201 was specifically designed to overcome this high-temperature sensitization issue and is **suitable for environments above \(315^ circ text{C}\)**, ensuring the material maintains its corrosive integrity at elevated operating temperatures. As a professional tube manufacturer, we meticulously control the chemical composition of raw materials and can flexibly supply either Nickel 200 or Nickel 201 based on the client’s specific operating temperature and application requirements, ensuring scientific and appropriate material selection.

Chapter II: Deep Dive into Nickel 200 Alloy Material Science: The Logic of Purity and Performance

2.1 Komposisi kimia: Purity as the Foundation of Performance

The core value of Nikel 200 lies in its chemical purity. The high-purity nickel matrix not only guarantees its excellent corrosion resistance but also delivers unique functional physical properties, such as high electrical conductivity and ferromagnetism. Jadual 1 details the primary chemical composition requirements stipulated by the UNS N02200 standard (referencing ASTM B163/B161), which serves as the mandatory benchmark for our tube production:

| unsur | UNS N02200 Standard (ASTM B163/B161) Max Content (%) | Significance and Impact |

|---|---|---|

| Nikel (Ni) + rintangan haus (Co) | Min. \(99.00\) | Ensures primary corrosion resistance, high ductility, kekonduksian, and magnetostrictive properties. |

| Karbon (C) | Max. \(0.15\) | Affects intergranular corrosion sensitivity (pemekaan) pada suhu tinggi. High C content is the key differentiator from Ni 201. |

| Tembaga (Cu) | Max. \(0.25\) | Strictly controlled to avoid compromising pure nickel’s stability in caustic alkali solutions. |

| besi (Fe) | Max. \(0.40\) | Impurity element, affects purity, electrical conductivity, and magnetic properties. tinggi \(\teks{Fe}\) content reduces conductivity. |

| Mangan (MN) | Max. \(0.35\) | Common deoxidizer, controlled to maintain purity and affects weldability. |

| Silikon (Si) | Max. \(0.35\) | Common deoxidizer, excessive content reduces ductility. |

| Sulfur (S) | **Max. \(0.01\)** | **Must be extremely low.** Sulfides severely impair high-temperature toughness, weldability, dan rintangan kakisan, easily causing hot shortness. |

| lain-lain | Max. \(0.10\) | Control of total residual impurities to ensure overall high purity. |

Jadual 1: Chemical Composition Requirements for Nickel 200 (UNS N02200) Tiub aloi

2.2 Sifat fizikal: The Basis for Functional Applications

The physical properties of high-purity nickel alloy make it unique across many sectors, particularly in electrical transmission and thermodynamics. Nikel 200 is ferromagnetic (below its Curie Temperature of about \(360^ circ text{C}\)) and possesses high thermal and electrical conductivity, an advantage many other nickel-based superalloys lack.

| Harta Fizikal | Nilai tipikal | Unit | Nota-Nota |

|---|---|---|---|

| Ketumpatan | \(8.89\) | \(\teks{g/cm}^3\) | Relatively heavy, reflecting the high-density packing of nickel atoms. |

| Julat Lebur | \(1435 – 1446\) | \(\teks{^ circ text{C}}\) | High melting point, lending good thermal stability for high-temperature applications. |

| Suhu Curie | \(360\) | \(\teks{^ circ text{C}}\) | Exhibits ferromagnetism below this temperature. |

| Thermal Expansion Coefficient | \(13.3 \times 10^{-6}\) | \(\teks{K}^{-1}\) | Average value between \(20^ circ text{C}\) dan \(100^ circ text{C}\). |

| Kekonduksian terma | \(70.2\) | \(\teks{W/(m}\cdot\text{K)}\) | Value at \(21^ circ text{C}\). Better than stainless steel and many Ni-Cr alloys, beneficial for heat exchange. |

| Kekonduksian Elektrik | \(\lebih kurang 15 – 20\) | \(\%\) IACS | Significantly higher than most nickel alloys, approaching the conductivity of copper, ideal for electronic applications. |

| Modulus Keanjalan | \(205\) | \(\teks{GPa}\) | Reflects the material’s stiffness, comparable to steel. |

Jadual 2: Typical Physical Properties of Nickel 200 Tiub aloi

2.3 Sifat-sifat mekanikal: Customization through Cold Work and Annealing

As a commercially pure nickel, Nikel 200 features excellent kemuluran and good cold-working characteristics, making it easy to perform precision cold drawing and rolling—a crucial requirement for manufacturing thin-walled, high-precision tubes. The final mechanical properties of the tube are largely dependent on its final heat treatment (cth., annealed or cold-drawn condition).

Jadual 3 lists the general mechanical property targets for **Annealed** Nickel 200 tiub, parameters that must be verified through tensile testing within our quality control system:

| Sifat mekanikal | Annealed Typical Value | Unit | ASTM B163 Minimum Requirement (Min.) |

|---|---|---|---|

| Kekuatan tegangan | \(400 – 550\) | \(\teks{MPa}\) | \(380\) |

| Kekuatan Hasil (0.2% Offset) | \(105 – 200\) | \(\teks{MPa}\) | \(105\) |

| Elongation | \(45 – 60\) | \(\%\) | \(35\) |

| Kekerasan Rockwell | \(60 – 75\) | \(\teks{HRB}\) | – |

Jadual 3: Mechanical Property Targets for Nickel 200 Tiub aloi (Keadaan Annealed)

Through precise control of the cold working reduction ratio and subsequent annealing process, we can tailor the tube’s final temper. Contohnya, dalam Sejuk disediakan condition can significantly increase its Yield Strength (selewat-lewatnya \(450 \teks{MPa}\) atau lebih) at the cost of some ductility, making it suitable for applications requiring higher structural strength. This precise capability to tune the final mechanical properties highlights our depth of expertise in tube manufacturing.

Chapter III: Deep Dive into the Superior Corrosion Resistance of Nickel 200

3.1 yang “Corrosion King” in Caustic Alkaline Media: Core Competency

Nikel 200 earns its reputation as the “Corrosion King” primarily from its unmatched resistance to corrosion in Caustic Alkalis such as Sodium Hydroxide (\(\teks{NaOH}\)) and Potassium Hydroxide (\(\teks{KOH}\)). These aggressive chemicals, even at high concentrations and temperatures, severely attack most stainless steels and Nickel-Chromium-Iron alloys.

Nickel 200’s Corrosion Resistance Mechanism: The surface of nickel rapidly forms a thin, dense, and highly stable passive oxide film (\(\teks{NiO}\)). This oxide film is chemically inert and extremely stable in strong alkaline solutions. It effectively isolates the metal substrate from the corrosive medium, providing superior, long-term corrosion protection. The stability of this passive film is the crucial factor that allows Nickel 200 to outperform other alloys.

- Caustic Soda (\(\teks{NaOH}\)) aplikasi: Nikel 200 exhibits excellent performance in nearly all concentrations and temperatures of \(\teks{NaOH}\) solutions. In the Chlor-Alkali industry, where water is evaporated to concentrate \(\teks{NaOH}\), Nikel 200 tubes are the **standard material of choice** for heating and evaporator tubes, guaranteeing long equipment life and the purity of the \(\teks{NaOH}\) produk.

- **Reiterating High-Temperature Limits:** yang \(315^ circ text{C}\) temperature limit is vital. For high-temperature caustic service above this threshold, we **strongly recommend** using the ultra-low carbon Nikel 201 to mitigate the risk of sensitization and ensure the safety of long-term operation.

3.2 Complex Behavior in Acidic Environments and Aqueous Media

Nickel 200’s acid resistance is selective and highly dependent on the type of acid and the oxidation state of the solution:

- **Reducing Acids:** In non-oxidizing and de-aererated solutions of Hydrochloric Acid (\(\teks{HCl}\)) and Sulfuric Acid (\(\teks{H}_2 teks{Jadi}_4\)), Nikel 200 possesses some tolerance. The critical condition is de-aeration. The presence of even trace amounts of oxygen or oxidizing agents (seperti \(\teks{Fe}^{3+}\) ions) will break down the passive film formed in the reducing environment, causing a sharp increase in the corrosion rate.

- **Oxidizing Acids:** Nikel 200 **is unsuitable** for strong oxidizing acids such as Nitric Acid (\(\teks{HNO}_3\)) or concentrated Sulfuric Acid. In these media, the corrosion rate is prohibitively high. Higher Cr or Mo containing alloys (seperti \(\teks{Inconel}\) atau \(\teks{Hastelloy}\) seri) are typically required here.

- **Aqueous Media and Salt Water:** In neutral and alkaline salt solutions, as well as stationary or low-velocity fresh water, corrosion resistance is good. Walau bagaimanapun, in high-velocity seawater or in stagnant areas with deposits, the risk of Mengadu dan Crevice Corrosion increases. For applications requiring better seawater resistance, alloys with higher resistance to chloride ions, seperti \(\teks{Ni-cu}\) series alloys (\(\teks{Monel 400}\)), are often chosen.

3.3 Resistance to Dry Halogen Gases and High-Temperature Oxidation

- **Dry Halogens:** Pada suhu yang tinggi, Nikel 200 shows good corrosion resistance in dry halogen gases such as Chlorine (\(\teks{Cl}_2\)) and Fluorine (\(\teks{F}_2\)). Walau bagaimanapun, this requires the atmosphere to be **absolutely dry**, as the presence of moisture significantly accelerates the corrosion reaction.

- **High-Temperature Oxidation:** In dry, oxidizing air, Nickel 200’s resistance to oxidation is good, usable up to about \(1200^ circ text{C}\). Walau bagaimanapun, if the environment introduces **sulfur compounds** or **reducing gases**, the high-temperature performance of the nickel-based material is severely compromised. Nickel reacts with sulfur to form low-melting-point nickel sulfides, potentially leading to **Hot Shortness**.

Chapter IV: Precision Manufacturing and Quality Assurance System for Nickel 200 Tiub

4.1 Proses pembuatan: From Billet to High-Precision Seamless Tube

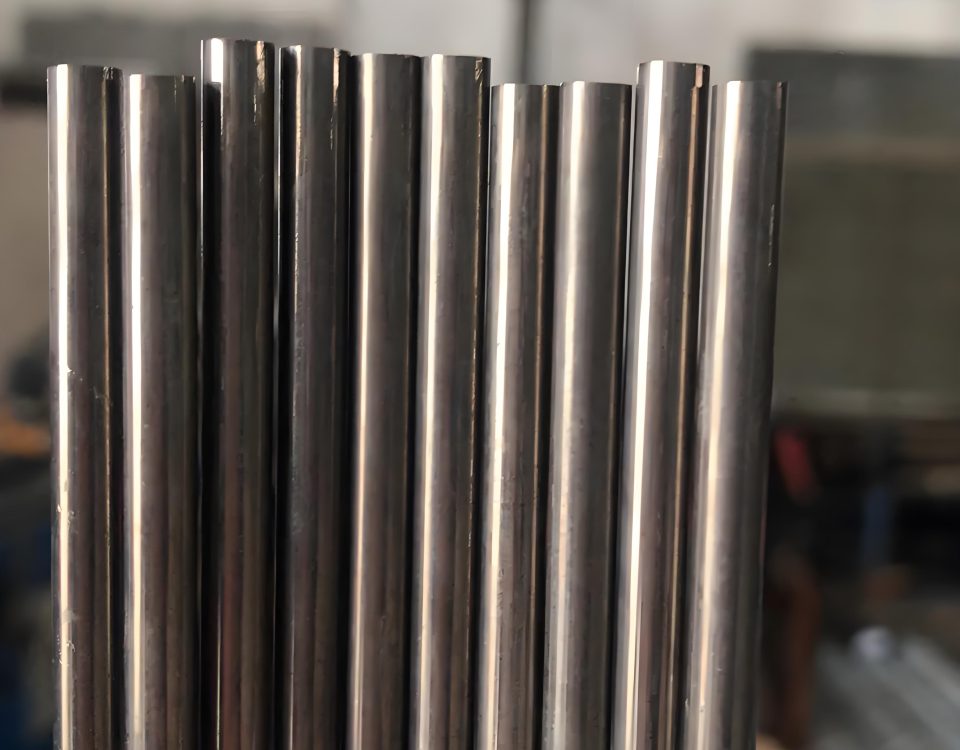

Our company is committed to manufacturing high-quality Nikel 200 Seamless and Welded Tubes. Seamless tubes, due to their superior wall thickness uniformity, higher structural integrity, dan kapasiti galas tekanan, are the ideal choice for critical pressure and high-temperature applications.

4.1.1 Seamless Tube Manufacturing: The Art of Cold Working

Manufacturing \(\teks{Nikel 200}\) seamless tubes is a complex, multi-step cold working process demanding extreme precision:

- **Raw Material Preparation and Analysis:** Start with solid round billets (Billet) that have been strictly melted and analyzed, meeting the \(\teks{UNS N02200}\) keperluan. This is the first step in ensuring product purity.

- **Piercing/Hot Extrusion:** The solid billet is heated and rotary pierced or processed via extrusion to create an initial thick-walled shell.

- **Cold Drawing or Cold Rolling:** This is the **core step** for manufacturing precision Nickel 200 tiub. Through repeated cold drawing/rolling cycles, the tube is gradually reduced in diameter and wall thickness. This process significantly improves the surface finish and dimensional accuracy while introducing **work hardening** that enhances mechanical strength.

- **Intermediate and Final Annealing:** Because Nickel 200 hardens rapidly during cold work, intermediate and final annealing are essential. **Tujuan:** To restore the metal’s ductility, relieve internal stresses, and allow the tube to be further processed or brought to its final required softened state. **Keperluan utama:** Annealing must be performed in a **strictly controlled inert or hydrogen atmosphere** (cth., **Penyepuhlap terang, BA**) to prevent surface oxidation and maintain a clean, high-luster finish.

- **Finishing and Surface Treatment:** After final sizing, tiub menjalani penjerukan atau penggilap mekanikal/kimia untuk membuang sebarang sisa oksida permukaan dan bahan cemar, mencapai kemasan permukaan licin (\(\teks{Ra}\) nilai) dikehendaki oleh pelanggan.

4.1.2 Pembuatan Tiub Dikimpal: Gabungan Ketulenan Tinggi

Tiub yang dikimpal dibentuk dengan menggulung Nikel ketulenan tinggi 200 jalur menjadi bentuk tiub dan kemudian menggunakan a Kimpalan Arka Tungsten Gas berterusan (\(\teks{Gtaw / giliran}\)) proses untuk menggabungkan jahitan membujur dengan ketulenan yang tinggi. Tiub yang dikimpal selalunya menjalani kerja sejuk dan penyepuhlindapan seterusnya untuk menghilangkan tegasan kimpalan dan menambah baik dimensi geometri.. Mereka sesuai untuk bukan tekanan tinggi, pemindahan bendalir tidak kritikal kerana keberkesanan kos dan fleksibiliti dimensinya.

4.2 Kawalan Kualiti yang Ketat dan Ujian Tidak Memusnahkan (NDT) Sistem

Bagi \(\teks{Nikel 200}\) tiub yang digunakan dalam kritikal, persekitaran yang agresif, sistem Kawalan Kualiti yang teguh adalah talian hayat yang memastikan kebolehpercayaan produk. Our quality system strictly adheres to \(\teks{ISO 9001}\) and fully complies with international standards such as $\text{ASTM}$, $\text{ASME}$, dan $\text{PED}$.

| Inspection Item | Kaedah | QC Objective |

|---|---|---|

| **Chemical Composition** | Spektroskopi, Wet Chemistry | Memastikan \(\teks{Ni} \ge 99.0\%\) and that impurities like \(\teks{C}\) dan \(\teks{Fe}\) meet \(\teks{UNS N02200}\) piawaian. This is the first critical checkpoint. |

| **Geometric Dimensions** | CMM, Precision Laser Measurement | Strict control over OD, ketebalan dinding (WT), ovality, kelurusan, and length tolerances. |

| **Surface Defects** | Pemeriksaan visual, Liquid Penetrant Test (PT) | Check for cracks, calar, lipatan, and delamination to ensure surface integrity. |

| **Internal Defects** | Ujian Ultrasonik (UT), Ujian Semasa Eddy (Et) | Detect internal inclusions, lompang, lack of weld penetration, and other hidden flaws, ensuring structural soundness. |

| **Pressure Integrity** | Ujian hidrostatik, Pneumatic Test | Verify the structural integrity and leak-tightness under specified internal pressure—mandatory for pressure vessel applications. |

| **Mechanical Properties** | Ujian tegangan, Ujian merobohkan, Ujian kekerasan | Verify that tensile strength, kekuatan alah, pemanjangan, and ductility meet standard requirements and custom needs. |

| **Intergranular Corrosion** | Ujian kakisan intergranular (cth., ASTM A262 Practice C) | Pastikan tiada pemekaan berlaku di zon yang terjejas haba selepas penyepuhlindapan atau kimpalan; terutamanya kritikal untuk \(\teks{Ni} 201\). |

Jadual 4: Kawalan Kualiti Utama dan Item Ujian Tidak Memusnahkan untuk Nikel 200 Tiub

Kami menyediakan komprehensif Laporan Ujian Bahan (Mtrs) untuk setiap kumpulan tiub, termasuk $3.1$ atau \(3.2\) sijil (disahkan oleh agensi pemeriksaan pihak ketiga bebas seperti $\text{TUV/SGS}$ atas permintaan), memastikan Kebolehkesanan Penuh daripada bahan mentah kepada produk akhir. Ini adalah komitmen yang serius kepada pelanggan kelas atasan global kami.

Bab V: Aplikasi Perindustrian Utama dan Pertimbangan Ekonomi Nikel 200 Tiub

5.1 Industri Kimia dan Petrokimia: Hati Pengendalian Kaustik

Ini adalah pasaran utama dan paling kritikal untuk Nikel 200, berpusat pada rintangan unggulnya terhadap alkali kaustik:

- **Pengeluaran Soda Kaustik:** **Ikatan Tiub Penyejat:** In the Chlor-Alkali industry, menumpukan perhatian \(\teks{NaOH}\) penyelesaian ialah langkah teras yang melibatkan penyejatan suhu tinggi. Nikel 200/201 tiub, kerana mereka tiada tandingan \(\teks{NaOH}\) rintangan kakisan, are widely used to manufacture heating and evaporator tubes, guaranteeing long equipment life and the purity of the \(\teks{NaOH}\) produk. **Heat Exchangers and Reactors:** Piping and equipment for transferring and processing other high-concentration alkaline chemicals, seperti \(\teks{KOH}\).

- **Organic Processing:** Nikel 200 resists mild corrosion while preventing metallic ion contamination when processing organic chemicals like fatty acids, phenols, and methanol, or during petroleum refining processes like asphalt desulfurization.

5.2 Electronics and Electrical Industries: The Value Chain of High Conductivity

High electrical conductivity is the key factor enabling Nickel 200’s role in the electronics sector, making it a high-performance conductive material:

- **Lithium Battery/Power Connections and Casings:** In high-power lithium-ion or Ni-Cd batteries, Nikel 200 tiub (or foil) are used as current leads, battery casings, or internal connectors, leveraging their low electrical resistance and excellent weldability for reliable current transmission.

- **Electro-Vacuum Devices and Heating Elements:** Nikel 200 is used as structural support or electron-emitting components in vacuum tubes, cathode ray tubes, and precision resistors, capitalizing on its low evaporation rate, high melting point, and good conductivity.

5.3 Food Processing and Pharmaceutical Industries: The Ultimate Demand for Purity

In health-related industries, material corrosion products must be extremely low to prevent contamination:

- **Food-Grade Equipment:** Piping and heat exchangers used to process fatty acids, glycerin, and high-purity water. Nickel 200’s chemical stability ensures the purity of the final food product, meeting standards like $\text{FDA}$ dan $\text{USP}$.

- **Pharmaceutical Synthesis:** In specific drug synthesis, distillation, and crystallization processes, Nikel 200 tubes are used in reactors and transfer systems to avoid metallic ion contamination, protecting sensitive catalysts and end-products.

5.4 Economic Considerations: Total Life Cycle Cost (TLC) Kelebihan

Although the initial procurement cost of a nickel alloy like Nickel 200 is higher than standard stainless steel, it offers a superior Total Life Cycle Cost (\(\teks{TLC}\)) advantage in aggressive service conditions:

- **Minimizing Downtime:** In the caustic alkali industry, any unexpected equipment corrosion failure leads to costly downtime and production losses. Nickel 200’s ultra-long service life means significantly reduced frequency of maintenance and replacement, delivering economic benefits that far outweigh the initial material cost.

- **Maintaining Production Efficiency:** Its superior thermal conductivity and resistance to fouling (especially in high-concentration \(\teks{NaOH}\) penyejat) membantu mengekalkan kecekapan pertukaran haba yang tinggi dari semasa ke semasa, sekali gus mengurangkan penggunaan tenaga dan kos operasi.

- **Mengurangkan Risiko Pencemaran:** Dalam industri ketulenan tinggi, satu kejadian pencemaran boleh merosakkan keseluruhan kumpulan, mengakibatkan kerugian ekonomi yang besar. Nikel 200 memastikan kebersihan proses pengeluaran dan kestabilan kualiti produk, menghalang kos tersembunyi.

Bab VI: Garis Panduan Fabrikasi untuk Nikel 200 Tiub: Intipati Amalan Kejuruteraan

6.1 Prosedur Kimpalan: Memastikan Kesucian dan Integriti

Nikel 200 mempamerkan kebolehkimpalan yang baik, tetapi prosedur yang ketat mesti diikuti untuk mengelakkan pencemaran, retak panas, dan pemekaan suhu tinggi:

- **Kebersihan:** **Ini ialah peraturan utama** untuk mengimpal aloi nikel. Permukaan tiub dan serong sambungan mesti dibersihkan dengan teliti dengan berus keluli tahan karat dan pelarut sebelum mengimpal untuk mengeluarkan semua minyak, skala, cat, and markings (especially low-melting-point crayon marks). Nickel alloys are highly susceptible to low-melting-point impurities like sulfur and phosphorus, which readily cause **Hot Cracking**.

- **Kaedah Kimpalan:** Recommended use of **Gas Tungsten Arc Welding (\(\teks{Gtaw / giliran}\))** atau \(\teks{MIG/GMAW}\). These methods provide inert gas shielding, minimizing oxidation and nitridation in the weld zone.

- **Filler Metal:** The most recommended filler metals for \(\teks{Ni} 200\) tubes are **\(\teks{ERNi}-1\) (AWS A5.14)** atau **\(\teks{Ni} 208\)**. Choosing the appropriate filler metal is critical to ensuring the weld joint possesses corrosion resistance and mechanical strength matching the base metal.

- **Post-Weld Stress Relief Annealing:** If the tube has undergone significant cold work before welding, or if there is a high concentration of stress in the weld area, **Post-Weld Stress Relief Annealing** may be considered. This reduces residual tensile stress, effectively preventing **Stress Corrosion Cracking (\(\teks{SCC}\))** in specific media like hot caustic alkalis.

6.2 Machining and Cold Forming Guidelines

Due to Nickel 200’s high ductility and relatively rapid work hardening rate, special precautions must be taken during machining and cold forming:

- **Pemesinan:** Nikel 200 is somewhat sticky and tends to gall onto cutting tools. This requires using cutting parameters characterized by **high power, low speed, and high feed rates**. Use sharp, positive-rake, high-strength carbide tools, coupled with ample cutting fluid for adequate cooling and lubrication to carry away heat and prevent tool wear and material adhesion.

- **Pembentukan Sejuk:** Nickel 200’s excellent ductility makes it easy to perform cold forming operations such as bending, menyala, and swaging. Walau bagaimanapun, because it **work hardens rapidly**, for large deformation requirements (cth., U-bending, deep drawing), it may be necessary to perform one or more **intermediate annealing** treatments during forming to restore ductility and prevent cracking due to hardening.

Chapter VII: Standards Compliance, Custom Services, and Our Corporate Commitment

7.1 International Standards and Specification Compliance

Our manufactured Nickel 200 / UNS N02200 tubes strictly comply with the world’s major industrial standards and specifications. Adhering to these standards is not only a prerequisite for market access but also a demonstration of our commitment to product quality.

| Standard Name | Penerangan | Applicable Product Form |

|---|---|---|

| **ASTM B161** | Nickel Seamless Pipe and Tube | Thick-walled piping applications, wide size range. |

| **ASTM B163** | Seamless Nickel Tube for Condensers and Heat Exchangers | Thin-walled heat exchange applications, high dimensional accuracy required. |

| **ASME SB-161** | Corresponds to ASTM B161 for Boiler and Pressure Vessel Code | Pressure vessels and piping, requires safety certification compliance. |

| **ASME SB-163** | Corresponds to ASTM B163 for Boiler and Pressure Vessel Code | Pressure vessel heat exchange applications, requires safety certification compliance. |

| **DIN / EN 2.4066** | European standard material designation for Ni 200 | European market and project applications. |

Jadual 5: Major Applicable International Standards for Nickel 200 Tiub aloi

Our company possesses a complete quality management system capable of issuing Material Certificates compliant with $\text{EN 10204 3.1}$, and we can coordinate with customers to obtain certification from **Third-Party Inspection Agencies (\(3.2\)) ** to ensure the global usability and credibility of our products.

7.2 Custom Services Addressing Client-Specific Needs

We deeply understand that standard specification tubes often cannot meet the requirements of all critical operating conditions. Oleh itu, we offer highly customized manufacturing services, working closely with clients to solve engineering challenges:

- **Extreme Customization of Dimensions and Tolerances:** We can manufacture tubes ranging from micro-tubing to large-bore pipes, with various wall thicknesses and lengths, and tighten tolerances for specific projects to meet ultra-high precision installation demands.

- **Special Temper Conditions:** Based on the client’s precise needs for strength, kekerasan, dan kemuluran, we offer various temper conditions through customized heat treatment processes, including fully **Annealed**, **Light Cold Drawn**, or **Heavy Cold Drawn** states.

Chapter VIII: Metallurgical Extensions: mikrostruktur, Analisis Kegagalan, and Ultra-Precision Applications

8.1 The Microstructure and Performance Logic of Nickel 200 aloi

From a microscopic perspective, Nikel 200 is a single-phase solid solution characterized by a **Face-Centered Cubic (\(\teks{FCC}\)) crystal structure**.

- **FCC Structure and Ductility:** yang \(\teks{FCC}\) structure possesses multiple \(\teks{Slip Systems}\), which is the fundamental reason for \(\teks{Nikel 200}\)’s excellent ductility and toughness. It allows the material to undergo plastic deformation through dislocation movement under large strains without immediate brittle fracture.

- **Work Hardening Mechanism:** Cold working (such as cold drawing) introduces a large number of **Dislocations** into the \(\teks{FCC}\) kekisi. These dislocations become entangled and impede one another, forming dislocation walls that obstruct further plastic flow. The macroscopic result is a significant increase in yield strength and hardness. Justeru, by precisely controlling the cold working reduction and annealing temperature, we can accurately tune the tube’s final mechanical properties.

8.2 Ultra-Precision Applications for High-Purity Requirements

Memanfaatkan teknologi kerja sejuk dan rawatan permukaan ultra ketepatan, kami mampu membekalkan tiub khusus melebihi dimensi standard:

- **Teknologi Tiub Mikro:** Pembuatan tiub dengan diameter lebih kecil daripada \(1 \teks{mm}\) dan ketebalan dinding kurang daripada \(0.1 \teks{mm}\). Ini memerlukan lukisan sejuk ultra ketepatan berbilang peringkat dan cetakan berlian yang disesuaikan, semuanya sambil mengekalkan kesucian di atas \(99.0\%\). Tiub mikro adalah penting untuk **sarung pelindung sensor ketepatan**, **peranti implan perubatan**, dan **elemen pertukaran haba mikro**.

- **Tiub Kemasan Permukaan Sangat Tinggi:** Melalui kemasan permukaan dalaman khusus (seperti mengasah dalaman dan **Electropolishing (\(\teks{EP}\))**), kekasaran permukaan dalaman (\(\teks{Ra}\)) tiub boleh dikurangkan ke paras nanometer. Permukaan ultra licin ini berkesan menghalang pengekalan zarah, lekatan mikrob, dan bersisik dalam cecair, memenuhi permintaan kebersihan melampau **Penghantaran Cecair Ketulenan Tinggi semikonduktor** dan industri **biofarmaseutikal**.

Bab IX: Kesimpulan—Menjamin Kebolehpercayaan dan Kesucian

**Nikel 200 (UNS N02200)** tiub aloi telah mewujudkan diri mereka sebagai bahan asas yang tidak boleh ditukar ganti merentasi pelbagai industri kritikal—termasuk bahan kimia, elektronik, makanan, dan farmaseutikal—disebabkan oleh rintangan kakisan kaustik yang cemerlang, kekonduksian elektrik yang sangat baik, kestabilan haba yang baik, dan ciri kerja sejuk yang menggalakkan.

Syarikat kita, disokong oleh pengetahuan metalurgi yang mendalam, teknologi pembuatan ketepatan termaju, dan sistem kawalan kualiti yang ketat, memastikan bahawa setiap meter Nikel 200 tiub yang meninggalkan kemudahan kami memenuhi atau melebihi piawaian antarabangsa. Kami komited untuk menyediakan anda:

- Rangkaian Produk Komprehensif: Meliputi bentuk lancar dan dikimpal, pelbagai saiz, and temper conditions.

- Kebolehkesanan Penuh: Ensuring every tube batch is accompanied by complete $3.1$ / \(3.2\) certification documents.

- Expert Technical Support: Assisting you with optimal material selection and design to maximize the performance benefits of Nickel 200.

The Nickel 200 tube is more than just a metal product; it is our steadfast commitment to industrial safety, production efficiency, and product purity. We look forward to collaborating with you to advance industrial progress.