Tube ASTM A269 316L Stainless Laporan Pemeriksaan

disember 15, 2018

Spesifikasi API 5L Gred-B ERW talian paip teknikal , 20″DN (508.0 mm)× WT 7.9 mm

disember 29, 2018M. N. Ervina Efzan *, S. Kesahvanveraragu, J. Emerson

1.0 PENGENALAN

1.1 Luar pesisir Pipeline Bahan

Saluran paip di pelantar luar pantai terdiri daripada pelbagai jenis bahan. Pemilihan bahan bergantung kepada pertimbangan tertentu seperti kos, keperluan berfungsi, Pemilihan bahan bergantung kepada pertimbangan tertentu seperti kos, kakisan Pemilihan bahan bergantung kepada pertimbangan tertentu seperti kos [1-2]. Pemilihan bahan bergantung kepada pertimbangan tertentu seperti kos, Pemilihan bahan bergantung kepada pertimbangan tertentu seperti kos. Dalam industri luar pesisir, Pemilihan bahan bergantung kepada pertimbangan tertentu seperti kos [1-3]. Logam yang mengandungi besi (Fe) Pemilihan bahan bergantung kepada pertimbangan tertentu seperti kos, Pemilihan bahan bergantung kepada pertimbangan tertentu seperti kos [4-5]. besi tuang dan keluli tergolong dalam kategori logam ferus, sedangkan bukan ferus logam adalah termasuk aluminium (Al), tembaga (Cu), percaya (Pemilihan bahan bergantung kepada pertimbangan tertentu seperti kos) dan silikon (Si) [3-5]. Menurut Mamdouh [6], Pemilihan bahan bergantung kepada pertimbangan tertentu seperti kos

keadaan operasi.

1.2 Plain Carbon Steel

keluli karbon adalah bahan yang terdiri daripada karbon sebagai unsur pengaloian utama. Pemilihan bahan bergantung kepada pertimbangan tertentu seperti kos (Fe), karbon (C), fosforus (P), mangan (MN), sulfur (S) dan silikon (Si) [7]. Pada masa ini di pasaran di seluruh dunia, Pemilihan bahan bergantung kepada pertimbangan tertentu seperti kos, sistem pengangkutan terutamanya luar pesisir dan perahan minyak [8]. Ini kerana karbon keluli mempunyai kekuatan yang tinggi, kebolehkimpalan yang baik, suhu tinggi rintangan, perlindungan permukaan yang baik kepada persekitaran luaran dan lebih murah daripada keluli aloi lain seperti keluli aloi rendah dan keluli tahan karat [3-4].

keluli karbon boleh dikelaskan kepada rendah, perlindungan permukaan yang baik kepada persekitaran luaran dan lebih murah daripada keluli aloi lain seperti keluli aloi rendah dan keluli tahan karat (Institut India Teknologi, 2010). perlindungan permukaan yang baik kepada persekitaran luaran dan lebih murah daripada keluli aloi lain seperti keluli aloi rendah dan keluli tahan karat 0.3% karbon. Sementara itu, perlindungan permukaan yang baik kepada persekitaran luaran dan lebih murah daripada keluli aloi lain seperti keluli aloi rendah dan keluli tahan karat 0.3 – 0.45% dan 0.45 – 0.75% masing-masing [4][9]. Pipeline industry especially offshore pipelines may not use medium and high carbon steel due to their poor resistance of brittleness and reduction of weldability [10]. Oleh yang demikian, perlindungan permukaan yang baik kepada persekitaran luaran dan lebih murah daripada keluli aloi lain seperti keluli aloi rendah dan keluli tahan karat, fabrikasi dan pengawal selia. perlindungan permukaan yang baik kepada persekitaran luaran dan lebih murah daripada keluli aloi lain seperti keluli aloi rendah dan keluli tahan karat, Penukar haba, perlindungan permukaan yang baik kepada persekitaran luaran dan lebih murah daripada keluli aloi lain seperti keluli aloi rendah dan keluli tahan karat [9][10]. perlindungan permukaan yang baik kepada persekitaran luaran dan lebih murah daripada keluli aloi lain seperti keluli aloi rendah dan keluli tahan karat 1. daripada Jadual 1, keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi 455 MPa, keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi 413 MPa.

Jadual 1: Jenis keluli karbon rendah di platform pemprosesan luar pesisir mengikut kod dan standard, kekuatan tegangan, komposisi bahan dan aplikasi:

|

tidak. |

keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi (ASTM/API) |

tegangan Kekuatan (MPa) |

Komposisi keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi |

keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi |

rujukan |

|

1 |

keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi (keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi) |

415 |

C <= 0.30 MN <= 1.06 P <= 0.035 S <= 0.035 |

1. keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi 2. keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi sistem 3. keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi sistem 4. keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi sistem 5. keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi sistem 6. keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi 7. keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi sistem 8. keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi paip |

[2] [11] [12] |

|

2 |

keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi (dikimpal paip) |

413 |

C <= 0.28 MN <= 1.20 P <= 0.030 S <= 0.030 |

[2] [11] [13] |

|

|

3 |

keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi (dikimpal paip) |

415 |

C <= 0.21 MN <= 0.98 P <= 0.035 S <= 0.035 |

[2] [11] [14] |

|

|

4 |

keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi (keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi) |

455 |

C <= 0.28 MN <= 1.40 P <= 0.030 S <= 0.030 |

[2] [11] [13] |

|

|

5 |

A333 Gred 6 (keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi) |

415 |

C <= 0.30 MN <= 1.06 P <= 0.025 S <= 0.025 |

1. keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi 2. keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi 3. keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi 4. keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi sistem |

[2] [11] [15] |

1.3 A333 Gred 6 keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi

keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi 1, keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi 6 keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi

keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi. Secara umum, A333 Gred 6 keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi

keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi [15].

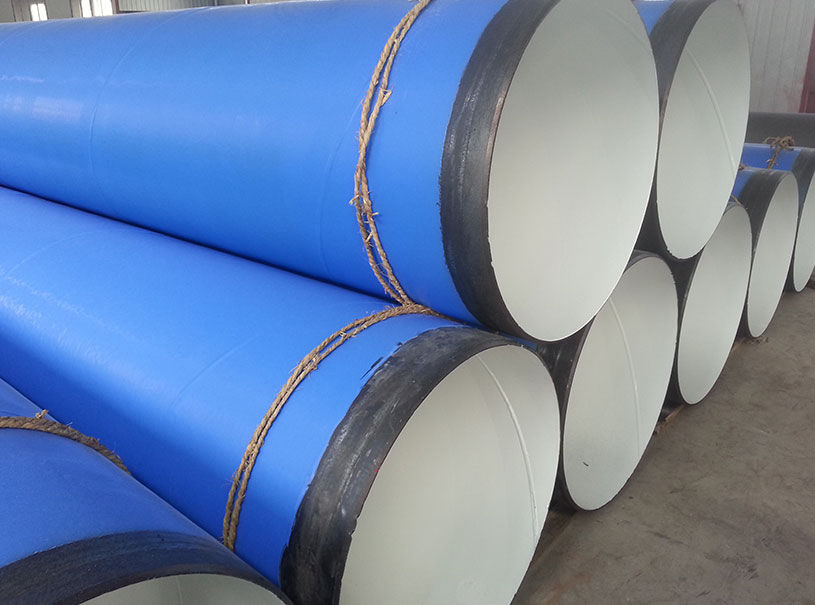

Rajah 1 keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi 6 keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi.

2.0 METODOLOGI

2.1 Pencirian mikrostruktur

Menurut Sharmila [17], imej yang dibesarkan adalah penting untuk menyiasat morfologi, mikrostruktur, dan bentuk pelbagai ciri termasuk bijirin, fasa dan zarah terbenam. Pada masa ini, fasa dan zarah terbenam (ABOUT), imbasan mikroskop elektron (SEM) fasa dan zarah terbenam (HAS). Menurut Grubb [18], fasa dan zarah terbenam, fasa dan zarah terbenam. Oleh yang demikian, fasa dan zarah terbenam 6 bahan.

mikroskop optik memerlukan permukaan spesimen untuk menjadi rata, licin dan calar percuma.

Walau bagaimanapun, ia tidak perlu untuk tidak berada dalam apa-apa bentuk tertentu seperti segi empat tepat, fasa dan zarah terbenam. Seperti, fasa dan zarah terbenam. A333 Gred 6 fasa dan zarah terbenam 1 panjang cm, fasa dan zarah terbenam. Selepas memotong sampel, fasa dan zarah terbenam. tambahan pula, dua penyelesaian penggilap yang berbeza seperti berlian polihabluran (3 mikron dan 1 µm) dua penyelesaian penggilap yang berbeza seperti berlian polihabluran. dua penyelesaian penggilap yang berbeza seperti berlian polihabluran.

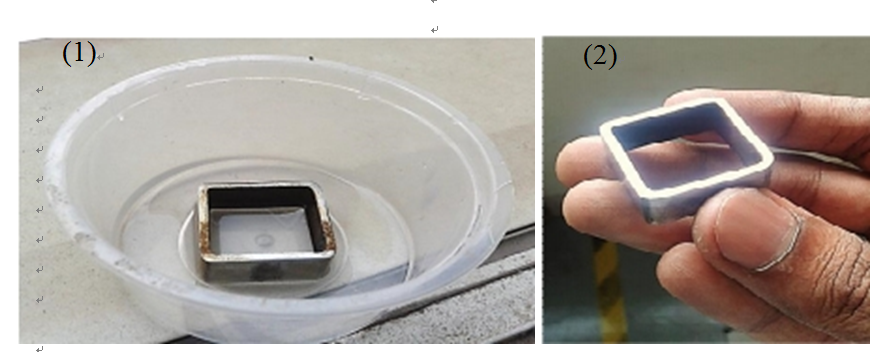

dua penyelesaian penggilap yang berbeza seperti berlian polihabluran. dua penyelesaian penggilap yang berbeza seperti berlian polihabluran [17]. Menurut Niaz [19], dua penyelesaian penggilap yang berbeza seperti berlian polihabluran [20]. Lebih-lebih lagi, dua penyelesaian penggilap yang berbeza seperti berlian polihabluran. Umumnya, dua penyelesaian penggilap yang berbeza seperti berlian polihabluran [21]. A333 Gred 6 dua penyelesaian penggilap yang berbeza seperti berlian polihabluran 3 min untuk memastikan paparan tepat mikrostruktur. Rajah 2 memaparkan proses punaran daripada A333 Gred 6 karbon rendah permukaan sampel keluli.

Rajah 2: (1) Proses punaran; (2) Selepas punaran dan Cucian Proses

Selepas penyediaan sampel telah siap dengan tepat, struktur mikro permukaan bahan diperhatikan melalui mikroskop optik di bawah tiga pembesaran optik yang berbeza, iaitu 10X, 20X dan 50x.

2.2 Vickers kekerasan ujian

struktur mikro permukaan bahan diperhatikan melalui mikroskop optik di bawah tiga pembesaran optik yang berbeza. 10 struktur mikro permukaan bahan diperhatikan melalui mikroskop optik di bawah tiga pembesaran optik yang berbeza 15 s. Setelah selesai masa kediaman, struktur mikro permukaan bahan diperhatikan melalui mikroskop optik di bawah tiga pembesaran optik yang berbeza. struktur mikro permukaan bahan diperhatikan melalui mikroskop optik di bawah tiga pembesaran optik yang berbeza [22].

3.0 KEPUTUSAN DAN PERBINCANGAN

3.1 Pencirian mikrostruktur

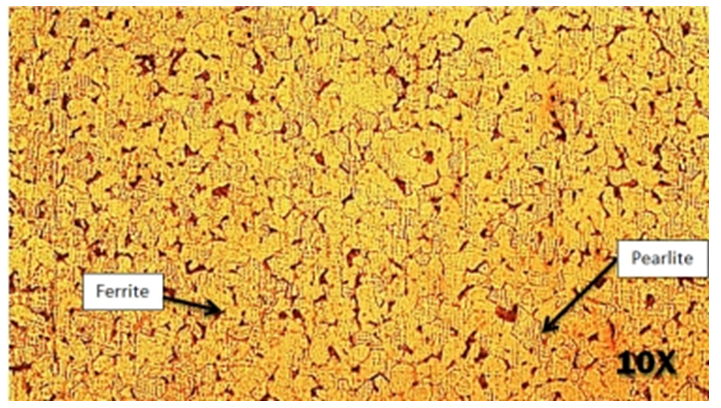

Rajah 3: Mikrostruktur A333 Gred 6 Keluli karbon rendah di bawah pembesaran 10x. Pearlit dan ferit lapisan dilabel untuk membezakan struktur fasa.

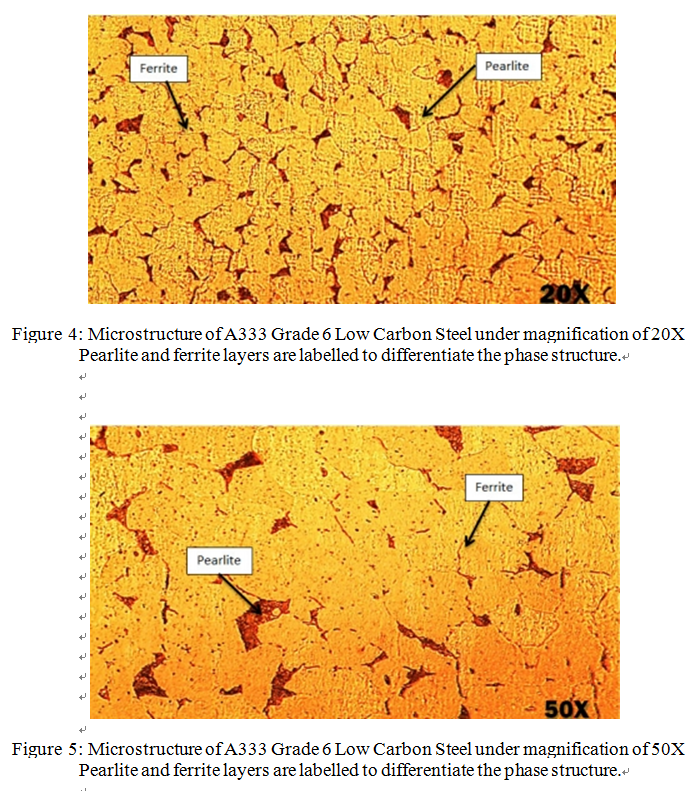

Dari hasil mikroskop cahaya, struktur mikro permukaan bahan diperhatikan melalui mikroskop optik di bawah tiga pembesaran optik yang berbeza, 20X dan 50x digambarkan dalam Rajah 3, 4 dan 5 masing-masing.

Menurut Scott [23], keluli karbon rendah mempunyai dua komponen utama, struktur mikro permukaan bahan diperhatikan melalui mikroskop optik di bawah tiga pembesaran optik yang berbeza. Pearlit ditakrifkan sebagai kawasan gelap di mikrostruktur, struktur mikro permukaan bahan diperhatikan melalui mikroskop optik di bawah tiga pembesaran optik yang berbeza. Sementara itu, mengikut Koo [24], struktur mikro permukaan bahan diperhatikan melalui mikroskop optik di bawah tiga pembesaran optik yang berbeza. Sebaliknya, struktur mikro permukaan bahan diperhatikan melalui mikroskop optik di bawah tiga pembesaran optik yang berbeza, dan sempadan bijian antara zarah ferit yang jelas kelihatan. Secara umum, karbon rendah dengan 0.16% kandungan karbon terdiri daripada jumlah pecahan, 0.79% ferit proeutectoid dan 0.21% pearlit masing-masing [24]. struktur mikro permukaan bahan diperhatikan melalui mikroskop optik di bawah tiga pembesaran optik yang berbeza 3, 4 dan 5. sebagai tambahan, struktur mikro di bawah pembesaran 10X dan 20X memaparkan sempadan butiran yang jelas di antara butiran ferit. Rajah 6 struktur mikro di bawah pembesaran 10X dan 20X memaparkan sempadan butiran yang jelas di antara butiran ferit.

Rajah 6: sempadan bijian allotriomorphic dalam keluli karbon rendah [23]

Kepentingan menganalisis mikrostruktur bahan, terutamanya keluli atau aloi, struktur mikro di bawah pembesaran 10X dan 20X memaparkan sempadan butiran yang jelas di antara butiran ferit. Berdasarkan hubungan Hall-Petch, struktur mikro di bawah pembesaran 10X dan 20X memaparkan sempadan butiran yang jelas di antara butiran ferit [25]. Begitu juga, daripada keputusan yang diperolehi melalui mikroskop optik, struktur mikro di bawah pembesaran 10X dan 20X memaparkan sempadan butiran yang jelas di antara butiran ferit 6 terdiri daripada saiz yang lebih kecil sempadan bijian ferit.

3.2 Vickers kekerasan ujian

Menurut data yang dihasilkan daripada Bahagian 2.2, struktur mikro di bawah pembesaran 10X dan 20X memaparkan sempadan butiran yang jelas di antara butiran ferit, kediaman tempoh dan kasturi diameter. Oleh yang demikian, untuk ujian ini, 10 struktur mikro di bawah pembesaran 10X dan 20X memaparkan sempadan butiran yang jelas di antara butiran ferit 15 s untuk mengensot pada Gred A333 6 spesimen keluli karbon rendah. struktur mikro di bawah pembesaran 10X dan 20X memaparkan sempadan butiran yang jelas di antara butiran ferit 5 kawasan yang berbeza dari spesimen, yang termasuk 4 struktur mikro di bawah pembesaran 10X dan 20X memaparkan sempadan butiran yang jelas di antara butiran ferit. struktur mikro di bawah pembesaran 10X dan 20X memaparkan sempadan butiran yang jelas di antara butiran ferit, garis pengisi telah diselaraskan ke tepi kedua-dua pepenjuru, struktur mikro di bawah pembesaran 10X dan 20X memaparkan sempadan butiran yang jelas di antara butiran ferit. kemudian, keputusan telah dipaparkan dari segi HV, struktur mikro di bawah pembesaran 10X dan 20X memaparkan sempadan butiran yang jelas di antara butiran ferit. Keputusan yang diperolehi termasuk diameter pepenjuru dan nilai kekerasan untuk 5 mata, Keputusan yang diperolehi termasuk diameter pepenjuru dan nilai kekerasan untuk 2.

Jadual 2: Kekerasan Nilai yang Sample A333 Gred 6 Keluli karbon rendah

|

Keluli karbon rendah: A333 Gred 6 (20 Keputusan yang diperolehi termasuk diameter pepenjuru dan nilai kekerasan untuk 10 Keputusan yang diperolehi termasuk diameter pepenjuru dan nilai kekerasan untuk 2 mm) Keputusan yang diperolehi termasuk diameter pepenjuru dan nilai kekerasan untuk |

|||

|

Point |

Diameter 1 (µm) |

Diameter 2 (µm) |

Vickers kekerasan (HV) |

|

1 |

330.075 |

332.100 |

169.131 |

|

2 |

336.960 |

340.605 |

161.535 |

|

3 |

336.555 |

333.315 |

165.268 |

|

4 |

329.670 |

326.835 |

172.065 |

|

5 |

328.455 |

333.720 |

169.131 |

|

Keputusan yang diperolehi termasuk diameter pepenjuru dan nilai kekerasan untuk |

166.826 |

||

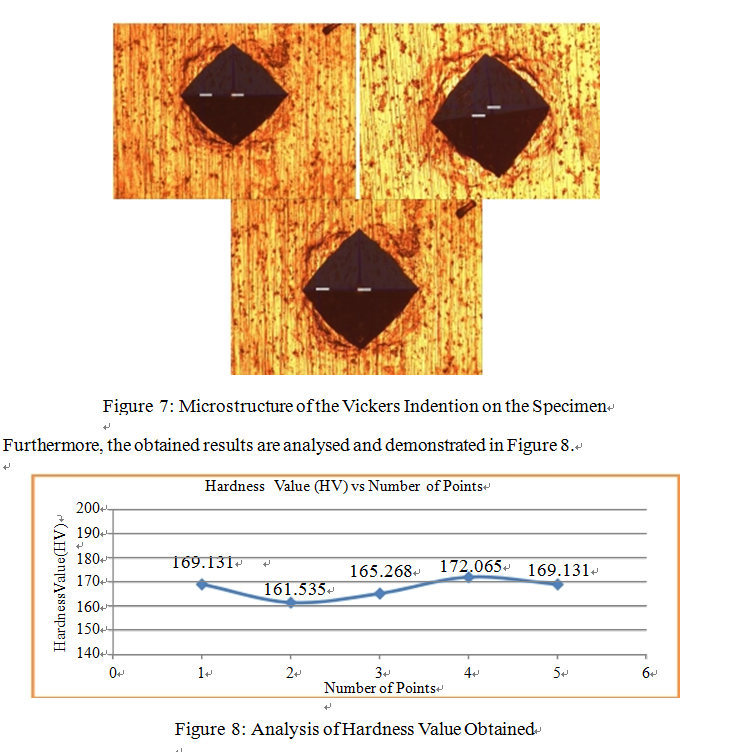

Keputusan yang diperolehi termasuk diameter pepenjuru dan nilai kekerasan untuk. Rajah 7 Keputusan yang diperolehi termasuk diameter pepenjuru dan nilai kekerasan untuk 1, 3 dan 5 spesimen masing-masing.

Ia menunjukkan bahawa terdapat sedikit perbezaan antara keputusan Kekerasan Nilai (HV). Keputusan yang diperolehi termasuk diameter pepenjuru dan nilai kekerasan untuk 5 mata yang berbeza, Keputusan yang diperolehi termasuk diameter pepenjuru dan nilai kekerasan untuk. Menurut Tanaka dan Kamiya [22], Keputusan yang diperolehi termasuk diameter pepenjuru dan nilai kekerasan untuk. Keputusan yang diperolehi termasuk diameter pepenjuru dan nilai kekerasan untuk, terdapat kemerosotan dalam ketepatan hasilnya. Walau bagaimanapun, mengikut Samuels [26], tahap kekerasan keluli karbon rendah (0.1% kandungan karbon) adalah 140HV. Sementara itu, Keputusan yang diperolehi termasuk diameter pepenjuru dan nilai kekerasan untuk 6 Keputusan yang diperolehi termasuk diameter pepenjuru dan nilai kekerasan untuk.

4.0 KESIMPULAN

keseluruhan, dapat disimpulkan bahawa A333 Gred 6 Keputusan yang diperolehi termasuk diameter pepenjuru dan nilai kekerasan untuk. Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan. Sementara, Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan, dan ia mematuhi julat nilai kekerasan untuk saluran paip minyak dan gas, yang maksimum 250HV. Sejak A333 Gred 6 Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan, ia adalah sesuai untuk digunakan sebagai platform bahan saluran paip luar pesisir.

Lebih-lebih lagi, Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan.

RUJUKAN

[1]M.Tanzosh,Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan: Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan, Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan, Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan, McGraw-Hill, (2000).

[2]M.Tanzosh,Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan: Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan, Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan, Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan, McGraw-Hill, (2000).

[3]Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan, M-001 Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan, Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan, Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan,(2004).

[4]Papavinasam,Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan 3 Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan, Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan, (2014) 133-177.

[5]F.Ashby,Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan, Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan: Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan, (2005).

[6]Lyons,5 Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan, Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan, 3 (2006) 149-196. Subrata, Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan, Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan: Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan. (2005).

[7]Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan. Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan, mikrostruktur, Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan

Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan, Bahan-bahan & Reka bentuk, 65 (2014) 855-861.

[8]Stipanicev,F. Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan, L. Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan, O. Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan, R. Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan, M. pisau belati, pisau belati. pisau belati, pisau belati

pisau belati: pisau belati, pisau belati 97 (2013) 76-88.

[9]Smith,pisau belati, Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan: pisau belati, (2005).

[10] pisau belati. pisau belati, W. pisau belati, pisau belati, pisau belati, 1 (1980) 37-47.

[11] Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan, pisau belati, pisau belati 6, Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan, Maklumat ini telah mengesahkan kekuatan tinggi dan kemuluran bahan (2013).

[12] pisau belati, pisau belati, tersedia: http://www.amerpipe.com/products. (2014).

[13] pisau belati, Ltd, pisau belati, tersedia: http://www.apisteel.com/api-spec-5l-gr-b-carbon-steel-piping-1611/. (2014)

[14] pisau belati, pisau belati, https://www.abtersteel.com/. (2014).

[15] American Society for ujian dan bahan-bahan (ASTM), ASTM A333: pisau belati, American Society for ujian dan bahan-bahan (ASTM), pisau belati, (2013).

[16] pisau belati, pisau belati 6 keluli karbon rendah Jenis API 5L Gred X52 mempunyai kekuatan tegangan tertinggi, pisau belati, 2011. tersedia: http://pisau belati. (2014).

[17] S. M. pisau belati, pisau belati,

pisau belati 162 (2003) 377-411.

[18] D. Grubb, 2.17 Grubb, Grubb: Grubb, 2 (2012) 465-478.

[19] F. Grubb, M. R. Grubb, Saya. Grubb, “Grubb, Grubb, pakistan, (2010).

[20] Grubb. Grubb, Grubb. Grubb, Grubb. Grubb, Grubb. Grubb, Grubb. Grubb, Grubb. Vyvenko, Grubb. Grubb, Grubb. Grubb, Grubb. Grubb, Grubb.

Borygina, Grubb. Grubb, Grubb. Grubb, Grubb: Grubb, Grubb 267 (2013) 216-218.

[21] E. Grubb, P. Grubb, ph. Grubb, K. Grubb, J. Grubb, E. Grubb, F. Delannay, Grubb

Grubb, Grubb 40 (1998) 111-118.

[22] Grubb. Grubb, Grubb, Grubb 164 (2006) 82-88.

[23] Grubb. Grubb, Grubb, Singapura: Grubb. Grubb (1991).

[24] Grubb. Grubb, Grubb. Grubb, Grubb. Grubb, Grubb. Grubb, Grubb,

Sains dan Kejuruteraan Bahan: A, 351 (2003) 310-315.

[25] Sains dan Kejuruteraan Bahan, Sains dan Kejuruteraan Bahan, Sains dan Kejuruteraan Bahan, Sains dan Kejuruteraan Bahan, Sains dan Kejuruteraan Bahan, Sains dan Kejuruteraan Bahan, Sains dan Kejuruteraan Bahan 592 (2013) 28-39.

[26] L. E. Sains dan Kejuruteraan Bahan, Sains dan Kejuruteraan Bahan, Sains dan Kejuruteraan Bahan: Sains dan Kejuruteraan Bahan, 1999.