Écran bobinés (Tuyau de filtre)

février 17, 2023

La demande de brides

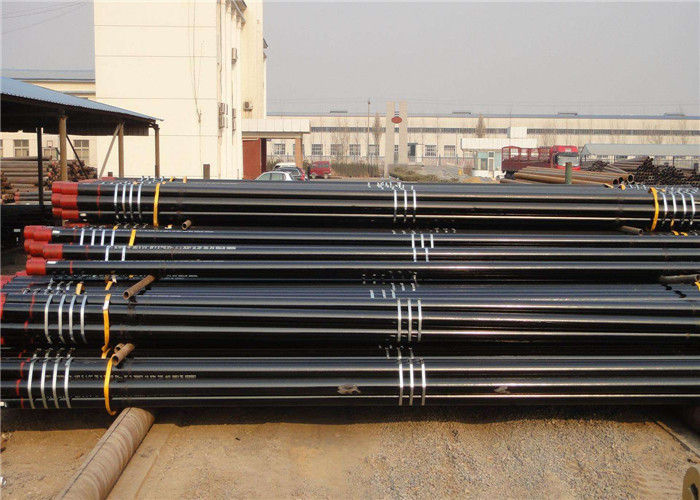

Mars 9, 2023La production de tubes en acier est un processus complexe qui nécessite une combinaison d'artisanat à l'ancienne et de technologie moderne. Le processus commence par la sélection des matières premières et se termine par la livraison du produit fini. L'ensemble du processus est divisé en plusieurs étapes, dont chacun est essentiel à la création de tuyaux en acier de la plus haute qualité.

La première étape de la production de tubes en acier est la sélection des matières premières. Les fabricants de tubes en acier achètent généralement de l'acier en bobines, bien que certains fabricants traitent des dalles d'acier. Les bobines sont découpées en bandes de la largeur et de la forme souhaitées, qui sont ensuite traités en fourrure. La forme du tuyau en acier peut varier, en fonction de l'application finale. Par exemple, un tuyau utilisé pour une conduite de gaz peut avoir une forme différente de celui utilisé pour les conduites d'eau.

Les bandes sont ensuite soumises à une série d'opérations qui les transforment en tubes ronds.. Les bandes sont d'abord chauffées dans un four puis passées à travers une série de rouleaux. Les rouleaux réduisent l'épaisseur de la bande d'acier et la façonnent en un tube rond .

La prochaine étape du processus est le soudage. Les fabricants de tubes en acier utilisent plusieurs méthodes de soudage, notamment le soudage à l'arc., soudage par résistance, et soudage à l'arc submergé. Chaque méthode a ses avantages et ses inconvénients selon l'application. Par exemple, le soudage à l'arc est une option rapide et économique, mais il ne convient pas à toutes les applications.

La prochaine étape dans la production de tubes en acier est l'ajout de revêtements et d'autres traitements. Le traitement le plus courant est la galvanisation, qui est l'application d'un revêtement de zinc sur la surface du tuyau en acier. Ce revêtement aide à protéger le tuyau contre corrosion et autres dommages environnementaux. Autres revêtements, comme l'époxy et le polyuréthane, peut également être appliqué sur le tuyau pour améliorer ses performances.

La dernière étape de la production de tubes en acier est l'inspection et les tests du produit fini.. Ceci est fait pour garantir que le tuyau répond à toutes les normes et spécifications applicables.. Les tuyaux sont testés pour leur résistance, durabilité, et résistance à la corrosion, ainsi que pour leur taille, forme, et l'épaisseur de paroi. Les tuyaux sont également inspectés pour déceler toute imperfection ou dommage qui aurait pu survenir pendant le processus de fabrication..

La production de tubes en acier est un processus complexe qui nécessite de nombreuses années d'expérience et d'expertise.. Avec la bonne combinaison de savoir-faire ancien et de technologie moderne, les fabricants de tuyaux en acier peuvent créer des tuyaux de haute qualité et fiables, durable, et en toute sécurité. Avec le bon niveau d'expérience, les fabricants de tubes en acier peuvent garantir que leurs produits répondent aux normes et spécifications les plus élevées. Avec la bonne attention aux détails, les fabricants de tubes en acier peuvent garantir que leurs produits sont de la plus haute qualité et peuvent être utilisés en toute sécurité dans une variété d'applications.

L'usine de tubes en acier est un incontournable de l'industrie manufacturière depuis quatre ans, fournir des tuyaux en acier de qualité à une variété d'industries. Pendant ce temps, l'usine a connu beaucoup de croissance et de développement, de l'introduction de nouvelles technologies et processus à l'expansion de sa clientèle. Cet article explorera les quatre années d’expérience de fabrication de l’usine de tubes en acier, examiner comment l'entreprise a évolué et ce qu'elle a réalisé.

Depuis sa création, l'usine de tubes en acier s'est consacrée à la production de tubes en acier de la plus haute qualité pour une variété d'applications. L'entreprise fabrique une gamme de tubes en acier standards et personnalisés en utilisant des technologies avancées de formage à froid et à chaud.. Tous les tuyaux sont fabriqués à partir de matières premières répondant à des normes de qualité strictes, garantir que les tuyaux sont durables et fiables. L'usine a également adopté une gamme de techniques avancées, comme le soudage et le filetage, pour garantir que les tuyaux sont de la plus haute qualité.

En plus de son engagement à produire des tubes en acier de haute qualité, l'usine de tubes en acier s'est également engagée à fournir un excellent service client. Cela est évident dans l’accent mis par l’usine sur la fourniture de livraisons dans les délais et de prix compétitifs.. L'entreprise a travaillé dur pour établir des relations solides avec ses clients, s'assurer que toutes les commandes sont exécutées rapidement et avec précision. L'usine propose également une gamme complète de services, y compris l'installation et la maintenance sur site, pour garantir que les clients aient la meilleure expérience possible.

Au cours des quatre dernières années, l'usine de tubes en acier a également connu un certain nombre de changements et d'améliorations. Afin de garder une longueur d'avance sur la concurrence, l'entreprise a adopté des techniques de production avancées, comme le soudage robotisé et la découpe automatisée. Cela a permis à l'usine de produire des tuyaux de meilleure qualité avec une plus grande cohérence et efficacité.. L'usine a également investi dans des équipements de pointe, tels que les bras robotisés et les machines d'inspection automatisées, pour garantir que tous les tuyaux répondent à des normes de qualité strictes.

Afin de garantir à ses clients la meilleure expérience possible, l'usine de tubes en acier propose également une gamme de services après-vente. L'entreprise offre une assistance technique et des conseils, ainsi que l'installation et la maintenance sur site. L'usine propose également des formations et des enseignements à ses clients, les aider à mieux comprendre les processus et les technologies utilisés pour produire des tubes en acier.

Au cours de ses quatre années d'activité, l'usine de tubes en acier a également connu une croissance significative. L'entreprise a élargi sa clientèle, accroître sa présence sur de nombreux marchés. en outre, l'usine a également augmenté sa capacité de production, lui permettant de répondre à la demande croissante de tubes en acier. L'entreprise a également constaté une nette amélioration de son efficacité, avec des délais de production de plus en plus courts et une satisfaction client croissante.

L'usine de tubes en acier a quatre années d'expérience réussie dans la fabrication, développer et élargir sa clientèle, investir dans des techniques de production avancées, et fournir un excellent service client. L'usine a également constaté une nette amélioration de son efficacité, et la satisfaction des clients augmente. Alors que l'usine de tubes en acier continue de croître et de se développer, il est sûr de rester un leader de l'industrie pendant de nombreuses années à venir.

-steel-pipe.jpg)