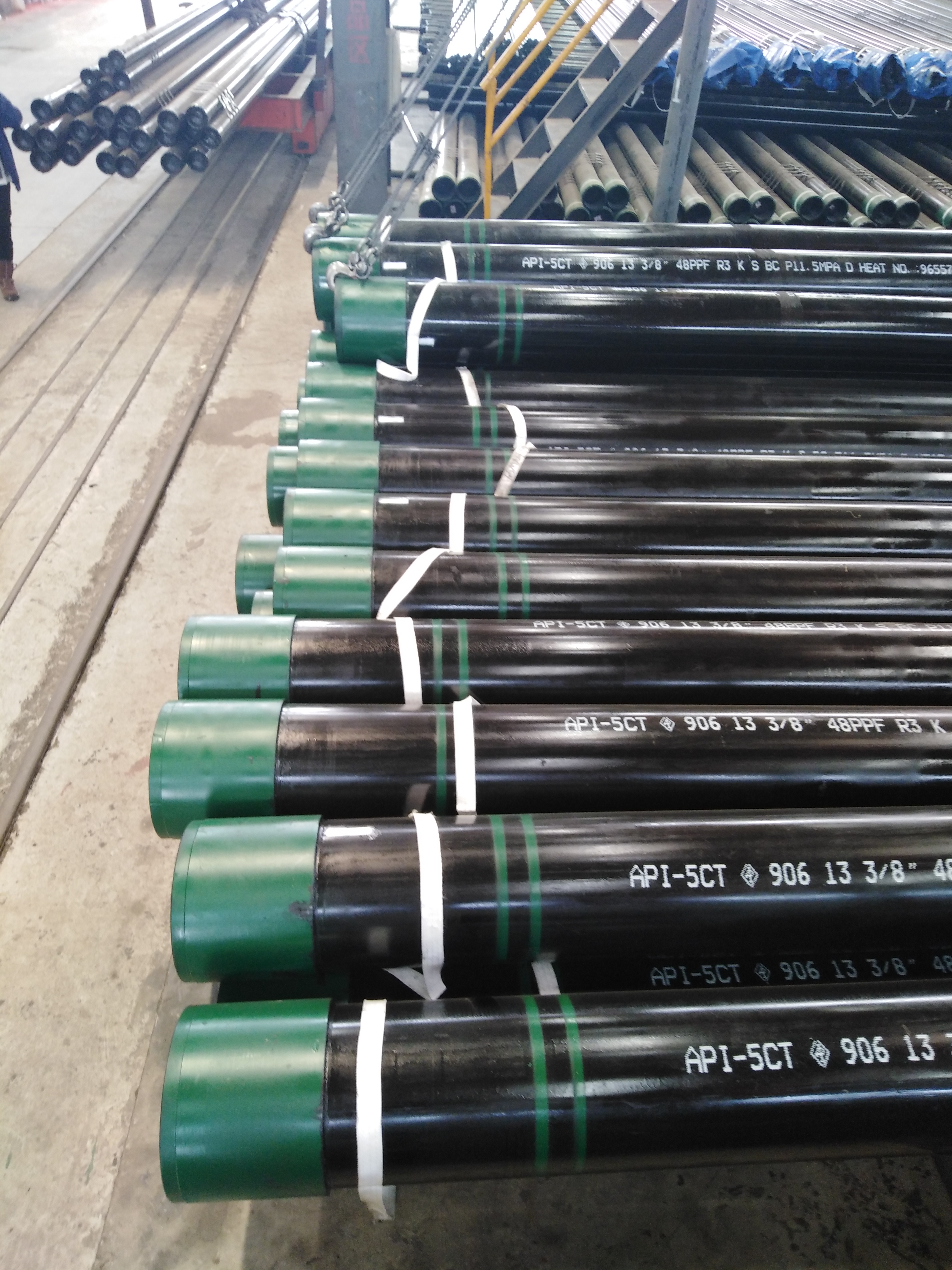

Một giới thiệu ngắn gọn về khoan ống thép

tháng tư 9, 2020

Các loại chủ đề vỏ được sử dụng

tháng tư 14, 2020Thép không gỉ được tạo thành từ các hợp kim sắt, crom (ít nhất 10.5%) và các hợp kim kim loại khác như niken, Titan, đồng hoặc molypden. Thiết yếu, it’s a family of heat and sự ăn mòn resistant metals combined to create an incredibly useful metal. The makeup of stainless steel varies depending on its intended use and corrosion resistance requirements. Stainless steel is available in a range of grades including Austenitic, Ferit, Martensitic and Duplex.

Making stainless steel involves a number of steps

- tan chảy&Vật đúc:The iron alloys are first melted together under extreme heat for around 8-12 hours.Once the metals are melted,they are cast into specific shapes(nở hoa,hóa đơn,slabs,rods and tube rounds)

- Hình thành:The steel is then hot rolled in order to form into its final shape.Blooms and billets are formed into bars and wires,and slabs become sheets,plates or strips.

- Chỉ số tính năng của thép được sử dụng làm phương pháp biểu diễn mã của nó:This involves the steel being heated and cooled under careful control to soften and relieve internal stresses.

- Descaling:The build-up formed on the steel during annealing is removed by using one of several descaling techniques.Annealing and descaling can occur at different steps depending on the type of steel that’s being worked.

- Cắt:Mechanical cutting involving shearing(guillotine knives for straight shearing or circular knives for circle shearing),cưa,blanking or nibbling is used to achieve the steel’s final size.It can also be flame cut,or cut using a plasma jet cutting method.

- Kết thúc:Surface finishing gives stainless steel its smooth and reflective appearance,while providing additional corrosion resistance.Bright,dull or mirrored finishes can be achieved depending on the steel’s intended use.